FLEISCHWIRTSCHAFT international 1/2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

............................................<br />

............................................<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

57<br />

Research &Development<br />

chicken meat while the treated group had 50% minced chicken meat.<br />

Noodles were formed by amanuallyoperated stainless steel extruder<br />

into around shape in atray and were dried in ahot air oven (SciTech) at<br />

65±2 °C for the required time (7 to 8h). The dried and cooled noodles<br />

were manuallybroken into 10 to 15 cm and were packed and sealed with<br />

asealer (Singhal, HSP-200, India) in pre-sterilised LDPE. The LDPE bags<br />

containing chicken meat noodles and control were kept at ambient<br />

temperature for further analysis of different physico-chemical parameters<br />

(moisture, fat, protein, crude fibre and ash), pH, water activity (aw),<br />

water absorption index (WAI), water solubility index (WSI), free fatty acid<br />

(FFA), 2-Thiobarbituric acid reactive substances (TBARS) value, textural<br />

profile analysis (TPA), microbial quality and sensory attributes during the<br />

storage study at ambient temperature of 35±2 °C up to 30 days.<br />

Analytical techniques<br />

Proximate composition<br />

The moisture, protein, fat and ash content of the chicken meat noodles<br />

were determined following standard methods as per (AOAC 1995).<br />

Crude fiber<br />

Crude fiber was determined by refluxing 2gof each sample with 100mlof<br />

0.3 NH2SO4 for 1h.The hot mixture was filtered through afibre sieve cloth.<br />

The residue obtained was returned to the flask and refluxed for another<br />

1hwith 100mlof0.3N NaOH solution. The mixture was filtered through a<br />

sieve cloth and the residue washed with 10 ml of acetone. The residue<br />

was then washed with 50 ml hot distilled water twice on the sieve cloth<br />

before it was finallytransferred into the crucible. The crucible with<br />

residue was oven dried at 105°Covernight, and weighed. The crucible and<br />

its content was then transferred into amuffle furnace set at 550 °C and<br />

heated for 4h,cooled and re-weighed. The weight of crude fibre was<br />

then calculated as g/100gof original sample (SAURA-CALIXTO et al. 1983).<br />

pH<br />

The pH of the noodles was determined according to (TROUT et al., 1992) by<br />

blending 10 gofsample with 100mldistilled water for 1min. using pestle<br />

and mortar.The pH of the suspension was recorded by dipping acombined<br />

glass electrode of an Elico pH meter (Model LI 127).<br />

Water activity (aw)<br />

Water activity was determined using ahand held portable digital water<br />

activity meter (Rotonix Hygro Palm AW1Set/40). Afinelyground sample<br />

was filled up (80%) in amoisture free sample cup provided along with the<br />

aw meter.The sample cup was placed into the sample holder, and then<br />

Source: VERMA et al. <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2017</strong><br />

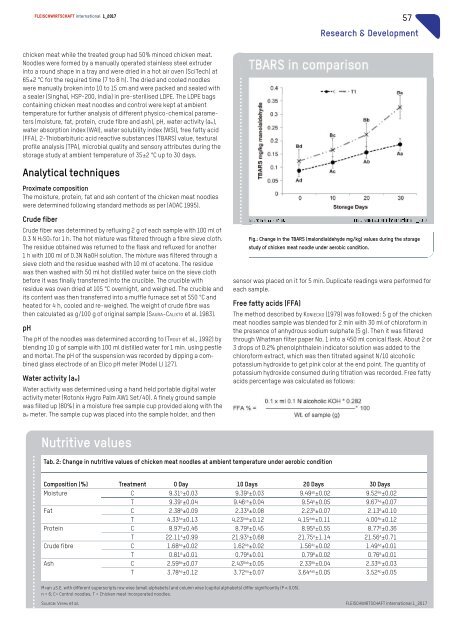

Fig.:Change in the TBARS (malondialdehyde mg/kg) values during the storage<br />

study of chicken meat noodle under aerobic condition.<br />

sensor was placed on it for 5min. Duplicate readings were performed for<br />

each sample.<br />

Free fatty acids (FFA)<br />

The method described by KONIECKO (1979) was followed: 5gof the chicken<br />

meat noodles sample was blended for 2min with 30 ml of chloroform in<br />

the presence of anhydrous sodium sulphate (5 g). Then it was filtered<br />

through Whatman filter paper No. 1into a450 ml conical flask. About 2or<br />

3drops of 0.2% phenolphthalein indicator solution was added to the<br />

chloroform extract, which was then titrated against N/10 alcoholic<br />

potassium hydroxide to get pink color at the end point. The quantity of<br />

potassium hydroxide consumed during titration was recorded. Free fatty<br />

acids percentage was calculated as follows:<br />

Tab. 2: Change in nutritive values of chicken meat noodles at ambient temperature under aerobic condition<br />

Composition (%) Treatment 0Day 10 Days 20 Days 30 Days<br />

Moisture C 9.31 b ±0.03 9.39 b ±0.03 9.49 ab ±0.02 9.52 Ba ±0.02<br />

T 9.39 c ±0.04 9.46 cb ±0.04 9.54 b ±0.05 9.67 Aa ±0.07<br />

Fat C 2.38 B ±0.09 2.33 B ±0.08 2.23 B ±0.07 2.13 B ±0.10<br />

T 4.33 Aa ±0.13 4.23 Aab ±0.12 4.15 Aab ±0.11 4.00 Ab ±0.12<br />

Protein C 8.97 B ±0.46 8.79 B ±0.45 8.95 B ±0.55 8.77 B ±0.36<br />

T 22.11 A ±0.99 21.93 A ±0.68 21.75 A ±1.14 21.56 A ±0.71<br />

Crude fibre C 1.68 Aa ±0.02 1.62 Ab ±0.02 1.56 Ac ±0.02 1.49 Ad ±0.01<br />

T 0.81 B ±0.01 0.79 B ±0.01 0.79 B ±0.02 0.76 B ±0.01<br />

Ash C 2.59 Ba ±0.07 2.43 Bab ±0.05 2.33 Bb ±0.04 2.33 Bb ±0.03<br />

T 3.78 Aa ±0.12 3.72 Aa ±0.07 3.64 Aab ±0.05 3.52 Ab ±0.05<br />

Mean ±S.E.withdifferent superscripts row wise (small alphabets) and column wise (capital alphabets) differ significantly(P