Porcelain - Augarten Porzellan

Porcelain - Augarten Porzellan

Porcelain - Augarten Porzellan

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

froM tHe Paste<br />

to uniQue<br />

PorCelain oBJeCts<br />

<strong>Porcelain</strong> Production<br />

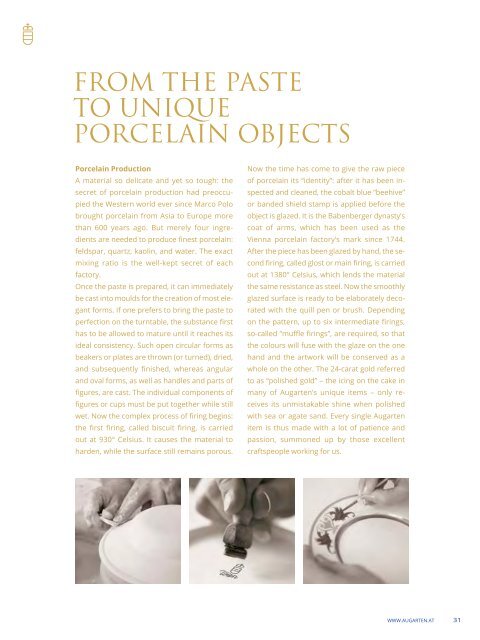

A material so delicate and yet so tough: the<br />

secret of porcelain production had preoccupied<br />

the Western world ever since Marco Polo<br />

brought porcelain from Asia to Europe more<br />

than 600 years ago. But merely four ingredients<br />

are needed to produce finest porcelain:<br />

feldspar, quartz, kaolin, and water. The exact<br />

mixing ratio is the well-kept secret of each<br />

factory.<br />

Once the paste is prepared, it can immediately<br />

be cast into moulds for the creation of most elegant<br />

forms. If one prefers to bring the paste to<br />

perfection on the turntable, the substance first<br />

has to be allowed to mature until it reaches its<br />

ideal consistency. Such open circular forms as<br />

beakers or plates are thrown (or turned), dried,<br />

and subsequently finished, whereas angular<br />

and oval forms, as well as handles and parts of<br />

figures, are cast. The individual components of<br />

figures or cups must be put together while still<br />

wet. Now the complex process of firing begins:<br />

the first firing, called biscuit firing, is carried<br />

out at 930° Celsius. It causes the material to<br />

harden, while the surface still remains porous.<br />

Now the time has come to give the raw piece<br />

of porcelain its “identity”: after it has been inspected<br />

and cleaned, the cobalt blue “beehive”<br />

or banded shield stamp is applied before the<br />

object is glazed. It is the Babenberger dynasty’s<br />

coat of arms, which has been used as the<br />

Vienna porcelain factory’s mark since 1744.<br />

After the piece has been glazed by hand, the second<br />

firing, called glost or main firing, is carried<br />

out at 1380° Celsius, which lends the material<br />

the same resistance as steel. Now the smoothly<br />

glazed surface is ready to be elaborately decorated<br />

with the quill pen or brush. Depending<br />

on the pattern, up to six intermediate firings,<br />

so-called “muffle firings”, are required, so that<br />

the colours will fuse with the glaze on the one<br />

hand and the artwork will be conserved as a<br />

whole on the other. The 24-carat gold referred<br />

to as “polished gold” – the icing on the cake in<br />

many of <strong>Augarten</strong>’s unique items – only receives<br />

its unmistakable shine when polished<br />

with sea or agate sand. Every single <strong>Augarten</strong><br />

item is thus made with a lot of patience and<br />

passion, summoned up by those excellent<br />

craftspeople working for us.<br />

www.augarten.at 31