The Potential of Electricity Generation from Poultry Waste in ...

The Potential of Electricity Generation from Poultry Waste in ...

The Potential of Electricity Generation from Poultry Waste in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

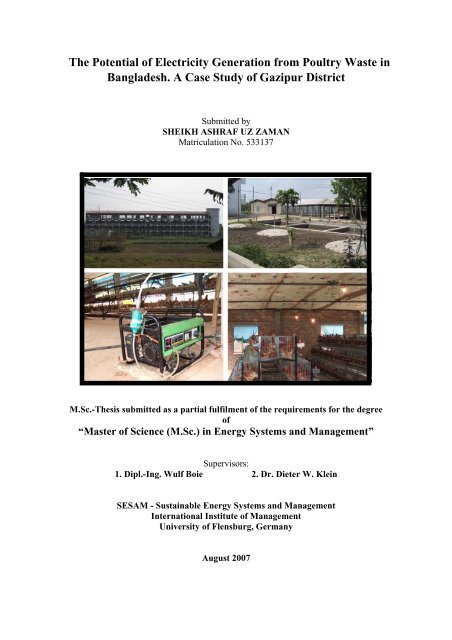

<strong>The</strong> <strong>Potential</strong> <strong>of</strong> <strong>Electricity</strong> <strong>Generation</strong> <strong>from</strong> <strong>Poultry</strong> <strong>Waste</strong> <strong>in</strong><br />

Bangladesh. A Case Study <strong>of</strong> Gazipur District<br />

Submitted by<br />

SHEIKH ASHRAF UZ ZAMAN<br />

Matriculation No. 533137<br />

M.Sc.-<strong>The</strong>sis submitted as a partial fulfilment <strong>of</strong> the requirements for the degree<br />

<strong>of</strong><br />

“Master <strong>of</strong> Science (M.Sc.) <strong>in</strong> Energy Systems and Management”<br />

Supervisors:<br />

1. Dipl.-Ing. Wulf Boie 2. Dr. Dieter W. Kle<strong>in</strong><br />

SESAM - Susta<strong>in</strong>able Energy Systems and Management<br />

International Institute <strong>of</strong> Management<br />

University <strong>of</strong> Flensburg, Germany<br />

August 2007

TABLE OF CONTENTS<br />

Title Page<br />

TABLE OF CONTENTS ........................................................................................................ii<br />

LIST OF ABBREVIATION ...................................................................................................v<br />

LIST OF TABLE ...................................................................................................................vii<br />

LIST OF FIGURES..............................................................................................................viii<br />

LIST OF UNITS.......................................................................................................................x<br />

ACKNOWLEDGEMENT......................................................................................................xi<br />

EXECUTIVE SUMMARY ...................................................................................................xii<br />

ZUSAMMENFASSUNG (Summary <strong>in</strong> German)..............................................................xvi<br />

CHAPTER 1 INTRODUCTION ........................................................................................1<br />

1.1 Background................................................................................................................1<br />

1.2 Objective <strong>of</strong> the Study ...............................................................................................2<br />

1.3 Research Question .....................................................................................................3<br />

1.4 Research Hypothesis:.................................................................................................3<br />

1.5 Significance <strong>of</strong> the Study:..........................................................................................4<br />

1.6 Overview <strong>of</strong> the Chapters ..........................................................................................4<br />

CHAPTER 2 BACKGROUND INFORMATION ............................................................5<br />

2.1 Country Background..................................................................................................5<br />

2.1.1 General Overview ...........................................................................................5<br />

2.1.2 Energy Sector <strong>in</strong> Bangladesh..........................................................................7<br />

2.1.3 <strong>Poultry</strong> Sector <strong>in</strong> Bangladesh........................................................................13<br />

2.2 Study Area Background...........................................................................................15<br />

2.2.1 Geography.....................................................................................................15<br />

2.2.2 Key Statistics <strong>of</strong> the Study Area ...................................................................16<br />

2.2.3 Available Energy <strong>in</strong>formation <strong>in</strong> the study area ...........................................16<br />

2.2.4 <strong>Poultry</strong> Sector <strong>in</strong> the Study Area ..................................................................17<br />

CHAPTER 3 METHODOLOGY .....................................................................................20<br />

3.1 Approach..................................................................................................................20<br />

3.2 Sampl<strong>in</strong>g Method.....................................................................................................21<br />

3.3 Data Collection ........................................................................................................22<br />

3.3.1 Secondary Data Collection ...........................................................................23<br />

3.3.2 Primary Data Collection ...............................................................................23<br />

3.4 Data Analysis...........................................................................................................23<br />

ii

TABLE OF CONTENTS (Contd…)<br />

Title Page<br />

3.5 Scenario Method ......................................................................................................24<br />

3.6 <strong>The</strong> Scope and Limitation <strong>of</strong> the Study ...................................................................25<br />

CHAPTER 4 ENERGY CONSUMPTION STATUS IN POULTRY FARMS ............27<br />

4.1 EXISTING UTILIZATION OF ELECTRICITY....................................................27<br />

4.1.1 <strong>Electricity</strong> consumption <strong>of</strong> major electrical appliances used........................27<br />

4.1.2 Daily <strong>Electricity</strong> Consumption Pattern .........................................................32<br />

4.1.3 <strong>Electricity</strong> Deficit and the Use <strong>of</strong> Back Up System......................................33<br />

4.2 EXISTING UTILIZATION OF OTHER ENERGY ...............................................35<br />

4.2.1 Use <strong>of</strong> Biogas + Size <strong>of</strong> Exist<strong>in</strong>g Biogas Plant.............................................35<br />

4.2.2 Use <strong>of</strong> Slurry and Disposal <strong>of</strong> <strong>Poultry</strong> <strong>Waste</strong> ...............................................36<br />

4.3 Attitudes and Barriers ..............................................................................................38<br />

CHAPTER 5 PRESENT STATUS OF ELECTRICITY GENERATION FROM<br />

POULTRY WASTE ...................................................................................39<br />

5.1 Some Properties <strong>of</strong> Biogas:......................................................................................41<br />

5.1.1 Characteristics <strong>of</strong> Biogas ..............................................................................41<br />

5.1.2 Impact <strong>of</strong> H2S................................................................................................42<br />

5.1.3 Impact <strong>of</strong> CO2 ...............................................................................................42<br />

5.2 Status <strong>of</strong> Technology Used <strong>in</strong> GTZ Flagship Project at Raj <strong>Poultry</strong> Farm .............43<br />

5.2.1 Biogas plant ..................................................................................................44<br />

5.2.2 H2S Removal Unit.........................................................................................45<br />

5.2.3 Moisture Removal Unit.................................................................................47<br />

5.2.4 Generator.......................................................................................................48<br />

5.2.5 Regeneration <strong>of</strong> Steel Wool and Silica Gel ..................................................49<br />

5.3 Status <strong>of</strong> Technology used <strong>in</strong> the Study Area:.........................................................49<br />

5.4 Status <strong>of</strong> Energy <strong>Generation</strong> ....................................................................................51<br />

5.5 Problems Encountered with the Technology (Owners’ View):...............................52<br />

CHAPTER 6 POTENTIAL OF ELECTRICITY GENERATION FROM POULTRY<br />

WASTE........................................................................................................53<br />

6.1 F<strong>in</strong>ancial Analysis....................................................................................................54<br />

6.1.1 Assumptions:.................................................................................................55<br />

6.1.2 Overview <strong>of</strong> Scenario result: ........................................................................60<br />

6.2 Analysis <strong>of</strong> Scenario I & II results:..........................................................................62<br />

6.3 Estimate <strong>of</strong> Total <strong>Potential</strong>.......................................................................................67<br />

6.4 Sensitivity Analysis .................................................................................................69<br />

6.4.1 Effect <strong>of</strong> variation <strong>of</strong> <strong>in</strong>vestment cost...........................................................69<br />

6.4.2 Effect <strong>of</strong> variation <strong>of</strong> Discount Rate .............................................................71<br />

iii

TABLE OF CONTENTS (Contd…)<br />

Title Page<br />

CHAPTER 7 CONCLUSION AND RECOMMENDATION........................................75<br />

7.1 Conclusions..............................................................................................................75<br />

7.2 Recommendation .....................................................................................................77<br />

BIBLIOGRAPHY..................................................................................................................78<br />

APPENDICES .....................................................................................................................81<br />

DECLARATION .................................................................................................................100<br />

iv

LIST OF ABBREVIATION<br />

°C : degree Celsius<br />

°F : degree Fahrenheit<br />

am : ante meridiem<br />

BB : Bangladesh Bank<br />

BBS : Bangladesh Bureau <strong>of</strong> Statistics<br />

BCAS : Bangladesh Centre for Advance Studies<br />

BCSIR : Bangladesh Council for Scientific and Industrial Research<br />

BDT : Bangladesh currency Taka<br />

BPDB : Bangladesh Power Development Board<br />

cc : cubic centimeter<br />

CDM : Clean Development Mechanism<br />

CFL : Compact Fluorescent Lamp<br />

CPP : Captive Power Plant<br />

dia : diameter<br />

DLO : District Livestock Officer<br />

DLS : Department <strong>of</strong> Livestock Services<br />

ft 3 : cubic feet<br />

g : gram<br />

GDP : Gross Domestic Product<br />

GS : Grameen Shakti<br />

GTZ : German Technical Cooperation<br />

GWh : Gigawatt hour<br />

HP : Horse Power<br />

HZ : Hertz<br />

IRR : Internal rate <strong>of</strong> return<br />

IPP : Independent Power Producer<br />

kg : kilogram<br />

kgoe : kilogram <strong>of</strong> oil equivalent<br />

KV : kilovolt<br />

kW : Kilowatt<br />

kWh : Kilowatt hour<br />

v

LIST OF ABBREVIATION (Contd…)<br />

l : litre<br />

LGED : Local Government Eng<strong>in</strong>eer<strong>in</strong>g Department<br />

LPG : Liquid Petroleum Gas<br />

m³ : Cubic meter<br />

MJ : Mega Joule<br />

MMCF : Million cubic feet<br />

MW : Megawatt<br />

MWh : Megawatt hour<br />

NEP : National Energy Policy<br />

NPV : Net present value<br />

PBP : Pay back period<br />

PBS : Palli Bidyuit Samity<br />

pm : post meridiem<br />

PPA : Power Purchase Agreement<br />

ppm : parts per million<br />

PVC : Polyv<strong>in</strong>yl chloride<br />

REB : Rural Electrification Board<br />

SPP : Small Power Plant<br />

sq km : square kilometer<br />

TCE : Ton <strong>of</strong> coal equivalent<br />

TCF : Trillion cubic feet<br />

TGTDCL : Titas Gas Transmission and Distribution Company Limited<br />

VAT : Value Added Tax<br />

vi

LIST OF TABLE<br />

Title Page<br />

Table 2.1 Estimated sizes <strong>of</strong> the poultry farms........................................................................14<br />

Table 2.2 Key Statistic <strong>of</strong> Gazipur District..............................................................................16<br />

Table 3.1 Sample distribution <strong>of</strong> different size <strong>of</strong> poultry farm ..............................................22<br />

Table 5.1 Heat<strong>in</strong>g values <strong>of</strong> commercial fuels and its correspond to Biogas..........................41<br />

Table 5.2 Test results <strong>of</strong> dry biogas produced <strong>from</strong> poultry litter ...........................................42<br />

Table 6.1 Cost <strong>of</strong> Generators ...................................................................................................57<br />

Table 6.2 F<strong>in</strong>ancial parameters................................................................................................60<br />

Table 6.3 Cost <strong>of</strong> different sizes generators <strong>from</strong> Fair Trade International.............................64<br />

Table 6.4 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation, fertilizer production and<br />

CO2 sav<strong>in</strong>gs <strong>in</strong> Scenario I ................................................................................................68<br />

Table 6.5 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation, fertilizer production and<br />

CO2 sav<strong>in</strong>gs <strong>in</strong> Scenario II...............................................................................................68<br />

Table 6.6 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation <strong>in</strong> GWh/ Year <strong>in</strong> Gazipur<br />

district ..............................................................................................................................71<br />

Table 6.7 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation <strong>in</strong> GWh/ Year <strong>in</strong><br />

Bangladesh.......................................................................................................................71<br />

Table 6.8 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation <strong>in</strong> GWh/ Year <strong>in</strong> Gazipur<br />

district ..............................................................................................................................73<br />

Table 6.9 Summary <strong>of</strong> estimated potential <strong>of</strong> electricity generation <strong>in</strong> GWh/ Year <strong>in</strong><br />

Bangladesh.......................................................................................................................74<br />

vii

LIST OF FIGURES<br />

Title page<br />

Figure 2.1 Show<strong>in</strong>g the Geography <strong>of</strong> Bangladesh ...................................................................6<br />

Figure 2.2 Consumption <strong>of</strong> natural gas by category <strong>of</strong> sectors..................................................7<br />

Figure 2.3 Total Installed Capacity by Type <strong>of</strong> Fuel.................................................................8<br />

Figure 2.4 Sector wise F<strong>in</strong>al Consumption <strong>of</strong> Commercial Energy ..........................................9<br />

Figure 2.5 Estimates <strong>of</strong> Energy Supplied by Traditional Fuels.................................................9<br />

Figure 2.6 Trend <strong>of</strong> growth <strong>of</strong> poultry birds <strong>in</strong> Bangladesh dur<strong>in</strong>g 2001-02 to 2005-06.......13<br />

Figure 2.7 Trend <strong>of</strong> growth <strong>of</strong> poultry farms <strong>in</strong> Bangladesh <strong>in</strong> different periods ...................13<br />

Figure 2.8 Geography <strong>of</strong> Gazipur District ...............................................................................15<br />

Figure 2.9 Upazillawise total number <strong>of</strong> poultry farm ............................................................18<br />

Figure 2.10 Upazillawise total number <strong>of</strong> poultry bird............................................................18<br />

Figure 2.11 Average number <strong>of</strong> bird <strong>in</strong> layer farm <strong>in</strong> different upazilla .................................19<br />

Figure 3.1 Sample distribution accord<strong>in</strong>g to upazilla and biogas plant...................................22<br />

Figure 4.1 Show<strong>in</strong>g different types <strong>of</strong> lamp ............................................................................28<br />

Figure 4.2 <strong>The</strong> percentage <strong>of</strong> poultry farms us<strong>in</strong>g different types <strong>of</strong> bulb ..............................28<br />

Figure 4.3 Show<strong>in</strong>g Fan...........................................................................................................29<br />

Figure 4.4 Duration <strong>of</strong> us<strong>in</strong>g fan <strong>in</strong> poultry farms...................................................................30<br />

Figure 4.5 Show<strong>in</strong>g the brooder...............................................................................................31<br />

Figure 4.6 Show<strong>in</strong>g Electric Pump and Hand Tube Well........................................................32<br />

Figure 4.7 <strong>The</strong> daily electricity consumption pattern <strong>in</strong> summer ............................................33<br />

Figure 4.8 <strong>The</strong> daily energy consumption pattern <strong>in</strong> w<strong>in</strong>ter....................................................33<br />

Figure 4.9 Duration <strong>of</strong> load shedd<strong>in</strong>g frequency .....................................................................34<br />

Figure 4.10 Percentage <strong>of</strong> back up system...............................................................................34<br />

Figure 4.11 Exist<strong>in</strong>g size <strong>of</strong> biogas plant as a percentage <strong>of</strong> total potential............................36<br />

Figure 4.12 Disposal <strong>of</strong> poultry dropp<strong>in</strong>gs ..............................................................................37<br />

Figure 5.1 Show<strong>in</strong>g different components <strong>of</strong> power plant at Bogra <strong>Poultry</strong> Complex ...........39<br />

Figure 5.2 Show<strong>in</strong>g different components <strong>of</strong> power plant at Bogra <strong>Poultry</strong> Complex ...........40<br />

Figure 5.3 Moisture filter and Generator set <strong>in</strong> Faridpur Muslim Mission .............................41<br />

Figure 5.4 Flow diagram <strong>of</strong> GTZ Flagship Project at Raj <strong>Poultry</strong> Farm.................................44<br />

Figure 5.5 Biogas plants <strong>in</strong> Raj <strong>Poultry</strong> Farm..........................................................................45<br />

Figure 5.6 Shows the H2S removal unit...................................................................................46<br />

Figure 5.7 Moisture removal unit ............................................................................................48<br />

viii

LIST OF FIGURE (Contd...)<br />

Title page<br />

Figure 5.8 Shows the generator and venturi ............................................................................49<br />

Figure 5.9 Flow diagram <strong>of</strong> produc<strong>in</strong>g electricity <strong>in</strong> the study area........................................50<br />

Figure 5.10 Different components <strong>of</strong> the plant........................................................................51<br />

Figure 6.1 Cost <strong>of</strong> bio gas plant...............................................................................................56<br />

Figure 6.2 NPV <strong>of</strong> different size <strong>of</strong> farms with different product for revenue under Scenario I<br />

.........................................................................................................................................61<br />

Figure 6.3 NPV <strong>of</strong> different size <strong>of</strong> farms with different product for revenue under Scenario II<br />

.........................................................................................................................................61<br />

Figure 6.4 IRR <strong>of</strong> different size <strong>of</strong> farms with different product for revenue under Scenario I<br />

.........................................................................................................................................62<br />

Figure 6.5 IRR <strong>of</strong> different size <strong>of</strong> farms with different product for revenue under Scenario II<br />

.........................................................................................................................................62<br />

Figure 6.6 IRR <strong>of</strong> different size <strong>of</strong> farms with cost digression <strong>of</strong> generators for Scenario I...65<br />

Figure 6.7 IRR <strong>of</strong> different size <strong>of</strong> farms with cost digression <strong>of</strong> generators for Scenario II .66<br />

Figure 6.8 IRR at different <strong>in</strong>vestment cost (1000 birds farm)................................................70<br />

Figure 6.9 IRR at different <strong>in</strong>vestment cost (1000 birds farm)................................................70<br />

Figure 6.10 NPV at different discount factor (3000 birds farm) .............................................72<br />

Figure 6.11 NPV at different discount factor (3000 birds farm) .............................................73<br />

ix

LIST OF UNITS<br />

1 Ton <strong>of</strong> coal equivalent = 0.695 Ton <strong>of</strong> oil equivalent<br />

1 Ton <strong>of</strong> coal equivalent = 27.55 ×10 6 British thermal unit<br />

1 MMSCF <strong>of</strong> natural gas = 172.3 barrels <strong>of</strong> crude oil equivalent<br />

1 MJ = 947.8171 British thermal unit<br />

1 GWh = 10 9 kWh<br />

1 kWh = 3.6 MJ<br />

1 HP = 0.746 kW<br />

1 MMCF = 28316.85 m³<br />

1 kgoe = 42 MJ = 11.63 kWh<br />

1 m 3 = 35.31 ft 3<br />

Currency conversion<br />

<strong>The</strong> exchange rate was considered at 68.50 BDT/ US$.<br />

Source: http://www.bangladesh-bank.org/econdata/exchangerate.php date:06.07.2007<br />

x

ACKNOWLEDGEMENT<br />

<strong>The</strong> author is grateful to express his s<strong>in</strong>cere gratitude to Deutscher Akademischer Austausch-<br />

Dienst (DAAD) for provid<strong>in</strong>g him an opportunity to pursue higher education <strong>in</strong> Germany.<br />

<strong>The</strong> author is also grateful to University <strong>of</strong> Flensburg, where he ga<strong>in</strong>ed <strong>in</strong>valuable academic<br />

knowledge dur<strong>in</strong>g sem<strong>in</strong>ar phase. In this connection, the author expresses his hearty gratitude<br />

to the pr<strong>of</strong>essors and lecturers who contributed a lot <strong>in</strong> the sem<strong>in</strong>ars. <strong>The</strong> author is gratified to<br />

express his deep s<strong>in</strong>cere thanks to Dipl.-Ing. Wulf Boie and Dr.Dieter W. Kle<strong>in</strong> for their<br />

valuable guidance and suggestion at different stages <strong>of</strong> this research. <strong>The</strong> author would like to<br />

express his gratitude to Pr<strong>of</strong>. Dr. M. A. Rashid Sarkar for supervis<strong>in</strong>g him dur<strong>in</strong>g the field<br />

research. <strong>The</strong>n his s<strong>in</strong>cere thanks go to Dr. Khursheed-Ul-Islam and Dr. M. Khaleq-uz-zaman<br />

<strong>of</strong> GTZ Bangladesh and Mr. M. A. G<strong>of</strong>ran <strong>of</strong> Grameen Shakti for support<strong>in</strong>g to carry out the<br />

field visit and provid<strong>in</strong>g relevant <strong>in</strong>formation <strong>of</strong> the study. <strong>The</strong> author also expresses his<br />

s<strong>in</strong>cere thanks to all the stakeholders <strong>of</strong> the study area for provid<strong>in</strong>g <strong>in</strong>formation regard<strong>in</strong>g<br />

this research. <strong>The</strong> author is also grateful to Titas Gas Transmission & Distribution Company<br />

Limited for giv<strong>in</strong>g the opportunity to pursue this study. At last but not least, the author<br />

expresses his s<strong>in</strong>cere thanks Ms. Khetsiwe Khumalo and Ms. Skadi Zscheile for their k<strong>in</strong>d<br />

cooperation.<br />

<strong>The</strong> Author<br />

xi

EXECUTIVE SUMMARY<br />

Introduction: <strong>The</strong> Per capita energy consumption <strong>in</strong> Bangladesh is 197 kg <strong>of</strong> oil equivalent<br />

(kgoe), which is far less than the averages for low <strong>in</strong>come (563 kgoe) countries 1 . Around<br />

33% (Hossa<strong>in</strong> and Tamim, 2005/2006, p. 16) <strong>of</strong> the total population is covered by electricity<br />

network and 4% (ibid, p. 13) are covered under natural gas network. About 40% <strong>of</strong> the total<br />

primary energy <strong>of</strong> the country comes <strong>from</strong> renewable energy, ma<strong>in</strong>ly biomass (Draft NEP,<br />

2006, p. 1). Biogas is one <strong>of</strong> the promis<strong>in</strong>g renewable energy sources <strong>in</strong> Bangladesh.<br />

Different sources <strong>of</strong> biogas <strong>in</strong> the country are cattle dung, poultry dropp<strong>in</strong>g, crop residue,<br />

kitchen waste etc. <strong>The</strong> country has a promis<strong>in</strong>g poultry <strong>in</strong>dustry to meet up the prote<strong>in</strong> need<br />

<strong>of</strong> the people. <strong>The</strong>re were about 130 thousand poultry farms <strong>in</strong> the country <strong>in</strong> 2005-2006 2 .<br />

<strong>The</strong> number <strong>of</strong> birds <strong>in</strong> poultry farms was about 194.82 million <strong>in</strong> 2005-2006 (ibid). <strong>The</strong>se<br />

poultry farms have a huge potential to produce biogas which can later be used to generate<br />

electricity. Recently, the government, non government organizations (NGO) and private<br />

entrepreneurs have <strong>in</strong>stalled small scale gas generators <strong>in</strong> some poultry farms to produce<br />

electricity. At the same time the poultry farms <strong>in</strong> the country are fac<strong>in</strong>g enormous power<br />

shortage every day which hampers the production <strong>of</strong> the <strong>in</strong>dustry. Dissem<strong>in</strong>ation <strong>of</strong> the<br />

technology could meet the poultry sector’s electricity demand as well as the need <strong>of</strong> adjacent<br />

households. This can reduce the burden on national electricity grid and contribute to the<br />

national economy as well.<br />

Objective: <strong>The</strong> ma<strong>in</strong> objective <strong>of</strong> the study was to identify the economic potential <strong>of</strong><br />

electricity generation <strong>from</strong> poultry waste <strong>in</strong> commercial poultry sector <strong>in</strong> Bangladesh.<br />

Methodology: <strong>The</strong> study was carried out as a case study <strong>in</strong> Gazipur district <strong>of</strong> Bangladesh<br />

dur<strong>in</strong>g April 2007 to June 2007. Data was collected by <strong>in</strong>terview<strong>in</strong>g poultry farmers with<br />

structured questionnaire, visit<strong>in</strong>g poultry farms, discussions and <strong>in</strong>terviews with key<br />

personnel and visit<strong>in</strong>g different concerned <strong>in</strong>stitutions. All the quantitative data was analyzed<br />

us<strong>in</strong>g Micros<strong>of</strong>t excel. To f<strong>in</strong>d out the m<strong>in</strong>imum size <strong>of</strong> poultry farm f<strong>in</strong>ancial analysis was<br />

done for different size <strong>of</strong> poultry farms. For f<strong>in</strong>ancial analysis, the technology used <strong>in</strong> GTZ<br />

flagship project at Raj <strong>Poultry</strong> Farm <strong>in</strong> Faridpur district was considered. Two different<br />

scenarios were considered <strong>in</strong> the analysis based on the time duration for which the poultry<br />

1<br />

http://www.acdis.uiuc.edu/Research/OPs/Samr<strong>in</strong>a/contents/part1.html, pr<strong>in</strong>ted on 18.08.2007<br />

2<br />

Data provided by Mr. A. S. Md. Abdul Hannan, Scientific Officer, Department <strong>of</strong> Livestock Services (DLS),<br />

Dhaka-1215, Bangladesh, 17.05.2007<br />

xii

farms can produce electricity. Scenario I considered electricity production for five hours <strong>in</strong><br />

the country peak hour while Scenario II considered electricity production for twelve hours,<br />

which is the total daily consumption <strong>of</strong> the poultry farms. Four different cases were<br />

considered under each scenario. <strong>The</strong> first case considered only electricity as a product to earn<br />

revenue, while the second case considered cost <strong>of</strong> CO2 and cost <strong>of</strong> electricity as revenue<br />

earn<strong>in</strong>g products. Third case considered the cost <strong>of</strong> fertilizer and cost <strong>of</strong> electricity as<br />

products to earn revenue and lastly, the fourth case considered CO2, fertilizer and electricity<br />

all together as revenue earn<strong>in</strong>g products. All these cases were considered under each scenario<br />

to f<strong>in</strong>d out the m<strong>in</strong>imum sizes <strong>of</strong> poultry farm. <strong>The</strong>n the potential <strong>of</strong> electricity production for<br />

different cases under different scenarios were estimated on the basis <strong>of</strong> sample data <strong>in</strong> the<br />

study area.<br />

Energy Consumption Status <strong>in</strong> <strong>Poultry</strong> Farms: <strong>Electricity</strong> is <strong>in</strong>evitable for the production<br />

<strong>of</strong> eggs and for the growth <strong>of</strong> the birds as well. <strong>Electricity</strong> is used <strong>in</strong> the <strong>in</strong>dustry ma<strong>in</strong>ly by<br />

lamps to provide proper light<strong>in</strong>g <strong>in</strong> the poultry shed, fans to ma<strong>in</strong>ta<strong>in</strong> the required<br />

temperature, brooder to brood up the chicks and the water pumps to supply water.<br />

<strong>The</strong> daily electricity consumption <strong>of</strong> poultry farms usually starts at about 10 am <strong>in</strong> the<br />

morn<strong>in</strong>g and cont<strong>in</strong>ues till 10 pm <strong>in</strong> the even<strong>in</strong>g. 100% poultry farms experience load<br />

shedd<strong>in</strong>g for about 4 hours a day mostly <strong>in</strong> the even<strong>in</strong>g. Only 30% <strong>of</strong> the farms have backup<br />

system to face power cut whereas the rest 70% does not have any back up system.<br />

Biogas produced <strong>in</strong> different poultry farms is used ma<strong>in</strong>ly for household cook<strong>in</strong>g. Very few<br />

poultry farms <strong>in</strong> Gazipur district and as well as <strong>in</strong> the country use biogas both for thermal<br />

purpose and produc<strong>in</strong>g electricity. About 38% farms can sell their biogas to at least one<br />

customer and the rest 62% does not have any market to sell it. So production <strong>of</strong> electricity<br />

could be an option to utilize the biogas properly. Only 8% <strong>of</strong> the farms use slurry as fertilizer,<br />

whereas the rest 92% does not use it as fertilizer due to lack <strong>of</strong> awareness <strong>of</strong> the farmers<br />

about the benefit <strong>of</strong> us<strong>in</strong>g it. At the same time, the exist<strong>in</strong>g law does not permit farmers to sell<br />

slurry without patent. Currently there is no market for slurry. However, few large farms sell<br />

slurry as fertilizer with patent.<br />

Present Status <strong>of</strong> <strong>Electricity</strong> <strong>Generation</strong> <strong>from</strong> <strong>Poultry</strong> <strong>Waste</strong>: <strong>Electricity</strong> production <strong>from</strong><br />

poultry waste is relatively new <strong>in</strong> Bangladesh. Different types <strong>of</strong> technologies are be<strong>in</strong>g used<br />

<strong>in</strong> different poultry farms <strong>in</strong> the country. <strong>The</strong> most common one is to use natural gas<br />

generator which uses biogas as fuel. Most <strong>of</strong> the farms which are produc<strong>in</strong>g electricity <strong>from</strong><br />

poultry waste do not have any H2S removal unit. H2S is severely corrosive to all metals<br />

xiii

associated with the transportation <strong>of</strong> gas and metal parts <strong>of</strong> eng<strong>in</strong>e which is driven by such<br />

gas conta<strong>in</strong><strong>in</strong>g H2S. To overcome these problems associated with H2S, GTZ Bangladesh has<br />

<strong>in</strong>stalled a flagship project at Raj <strong>Poultry</strong> Farm <strong>in</strong> Faridpur district which is more scientific<br />

than any other technology be<strong>in</strong>g used <strong>in</strong> the currently.<br />

F<strong>in</strong>ancial Analysis: On the basis <strong>of</strong> different assumption NPV, IRR and Payback Period<br />

were calculated for poultry farms with the sizes <strong>of</strong> 500, 1000, 2000, 3000, 4000, 5000, 6000,<br />

7000, 8000, 9000, 10000, 15000, 20000 and 50000 birds. <strong>The</strong> discount rate was considered at<br />

8% and the life <strong>of</strong> the project was considered 20 years. NPV, IRR and Payback Period were<br />

calculated for each size <strong>of</strong> poultry farms under both Scenarios I & II for four different cases.<br />

<strong>The</strong> calculation was done to f<strong>in</strong>d out the m<strong>in</strong>imum sizes <strong>of</strong> poultry farms which could<br />

produce electricity with f<strong>in</strong>ancial viability.<br />

It was found that poultry farms rang<strong>in</strong>g <strong>from</strong> 500 birds to 50000 birds all face negative NPV<br />

and lower IRR than the discount rate and very high payback period <strong>in</strong> the case when only<br />

electricity is considered as a product to earn revenue. In addition <strong>of</strong> CO2 cost with electricity<br />

cost can not make any size <strong>of</strong> poultry farm f<strong>in</strong>ancially viable <strong>in</strong> Scenario I where electricity is<br />

produced for five hours a day. On the other hand <strong>in</strong> Scenario II where electricity is produced<br />

for twelve hours a day, <strong>in</strong> addition <strong>of</strong> CO2 cost with electricity cost makes the farms<br />

f<strong>in</strong>ancially viable with a capacity <strong>of</strong> 6000 birds and above. In addition <strong>of</strong> fertilizer cost <strong>in</strong><br />

stead <strong>of</strong> CO2 cost with electricity cost, makes the farms f<strong>in</strong>ancially viable with the capacity <strong>of</strong><br />

1000 birds and above. In this case NPV was found positive, IRR is higher than the discount<br />

rate and pay back period is much lower than the project life. F<strong>in</strong>ally, the addition <strong>of</strong> CO2 cost<br />

with fertilizer and electricity cost also makes viable the farms with the capacity rang<strong>in</strong>g <strong>from</strong><br />

1000 birds and above. However, for the farm with capacity <strong>of</strong> 500 birds, it was found that<br />

NPV is negative and IRR is lower than the discount rate for even consider<strong>in</strong>g CO2, fertilizer<br />

and electricity all together as product to earn revenue.<br />

Estimate <strong>of</strong> Total <strong>Potential</strong>: <strong>The</strong>re is no economic potential <strong>in</strong> the study area as well as <strong>in</strong><br />

the country to produce electricity <strong>from</strong> poultry waste <strong>in</strong> this case if only electricity is<br />

considered as a product to earn revenue. <strong>The</strong> estimated potential to produce electricity is<br />

about 13 GWh <strong>in</strong> Gazipur district and 135 GWh <strong>in</strong> the country per year when CO2 cost is<br />

added with electricity cost provided electricity is produced for twelve hours a day for the total<br />

daily consumption <strong>of</strong> the farm. However, there is no economic potential if the electricity is<br />

produced for five hours a day only dur<strong>in</strong>g the country peak. <strong>The</strong> maximum estimated<br />

potential to produce electricity for Gazipur district and the country is 34 GWh/year and 360<br />

xiv

GWh/year respectively provided fertilizer cost is added with electricity cost irrespective <strong>of</strong><br />

numbers <strong>of</strong> hours <strong>of</strong> electricity generation.<br />

Conclusion: <strong>The</strong>re is a potential to produce electricity <strong>from</strong> poultry waste and there is high<br />

<strong>in</strong>terest <strong>from</strong> farmers to produce the electricity. This <strong>in</strong>terest has come due to the fact that all<br />

the poultry farms experience load shedd<strong>in</strong>g through out the day mostly <strong>in</strong> the even<strong>in</strong>g which<br />

hampers the production <strong>of</strong> the farm. <strong>Electricity</strong> can be produced <strong>from</strong> poultry waste for the<br />

total daily consumption <strong>of</strong> most <strong>of</strong> the poultry farms and <strong>in</strong> addition electricity can also be<br />

produced for the peak hour only to save farms <strong>from</strong> be<strong>in</strong>g cut <strong>of</strong>f. <strong>Electricity</strong> generation for<br />

12 hours through out the day is more f<strong>in</strong>ancially feasible than produc<strong>in</strong>g electricity for 5<br />

hours dur<strong>in</strong>g peak hour. However, only electricity as a product to earn revenue <strong>in</strong> not enough<br />

to make the poultry farms f<strong>in</strong>ancially viable to produce electricity. Fertilizer is the most vital<br />

element as a product to earn revenue with electricity to make poultry farms f<strong>in</strong>ancially<br />

feasible to produce electricity. <strong>The</strong>refore, to harness the energy <strong>from</strong> poultry waste <strong>in</strong> the<br />

national energy mix the amendment <strong>of</strong> exist<strong>in</strong>g law is required to elim<strong>in</strong>ate the bureaucratic<br />

obstacles and awareness rais<strong>in</strong>g is required among the people regard<strong>in</strong>g the benefit <strong>of</strong> slurry<br />

as fertilizer to create the market for slurry.<br />

xv

ZUSAMMENFASSUNG (Summary <strong>in</strong> German)<br />

E<strong>in</strong>leitung. Der Pro-Kopf-Energieverbrauch <strong>in</strong> Bangladesch beträgt 197 kgoe, was<br />

wesentlich unter dem Durchschnitt der e<strong>in</strong>kommensschwachen Länder liegt. Rund 33% der<br />

Gesamtbevölkerung s<strong>in</strong>d an das Stromnetz angeschlossen, 4% werden durch Erdgas versorgt.<br />

Etwa 40% der gesamten Primärenergie des Landes wird durch erneuerbare Energien<br />

gewonnen, überwiegend Biomasse. E<strong>in</strong>e der erfolgsversprechenden Quellen im Bereich der<br />

erneuerbaren Energien <strong>in</strong> Bangladesch ist Biogas. Zu den verschiedenen Biogasquellen des<br />

Landes gehören Kuhdung, Geflügeldung, Getreideabfälle, Küchenabfälle etc. Das Land<br />

besitzt e<strong>in</strong>e vielversprechende Geflügel<strong>in</strong>dustrie, die den Prote<strong>in</strong>bedarf der Menschen decken<br />

soll. In den Jahren 2005 bis 2006 gab es rund 130.000 Geflügelfarmen im Land. Die Anzahl<br />

der Vögel auf den Geflügelfarmen betrug dabei rund 194,82 Millionen. Diese<br />

Geflügelfarmen besitzen e<strong>in</strong> sehr großes <strong>Potential</strong>, Biogas zu produzieren, welches später zur<br />

Sromerzeugung verwendet werden kann. Kürzlich haben die Regierung,<br />

regierungsunabhängige Organisationen und private Unternehmer Kle<strong>in</strong>gasgeneratoren <strong>in</strong><br />

e<strong>in</strong>igen Geflügelfarmen angebracht, um Strom zu erzeugen. Gleichzeitig s<strong>in</strong>d die<br />

Geflügelfarmen im Land täglich Energieengpässen ausgesetzt, was die Produktion hemmt.<br />

Die Verbreitung der Technologie könnte den Elektrizitätsbedarf im Bereich der<br />

Geflügelzucht sowie den Bedarf der angrenzenden Haushalte befriedigen. Dies kann dann die<br />

Belastung auf das nationale Stromnetz verr<strong>in</strong>gern und e<strong>in</strong>en Beitrag zur Volkswirtschaft<br />

leisten.<br />

Ziel der Studie. Das Hauptziel der Studie war, das wirtschaftliche <strong>Potential</strong> der<br />

Stromerzeugung mittels Geflügeldung im kommerziellen Geflügelbereich <strong>in</strong> Bangladesch zu<br />

bestimmen.<br />

Methodik. Die Studie wurde als Fallstudie im Gazipur Bezirk von Bangladesch von April bis<br />

Juni 2007 durchgeführt. Daten wurden gesammelt, <strong>in</strong>dem Geflügellandwirte mit<br />

strukturiertem Fragebögen befragt und Geflügelfarmen besichtigt wurden. Außerdem wurden<br />

Diskussionen und Interviews mit Schlüsselpersonal geführt und unterschiedliche beteiligte<br />

E<strong>in</strong>richtungen besichtigt. Alle quantitativen Daten wurden mit Hilfe von Micros<strong>of</strong>t Excel<br />

analysiert. Um die m<strong>in</strong>imale Größe e<strong>in</strong>er Geflügelfarm zu bestimmen, wurde e<strong>in</strong>e f<strong>in</strong>anzielle<br />

Analyse für Geflügelfarmen mit unterschiedlicher Größe durchgeführt. Für die f<strong>in</strong>anzielle<br />

Analyse wurde die Technologie, die im GTZ Flaggschiffprojekt auf Raj Geflügelfarm im<br />

Faridpur Bezirk verwendet wurde, <strong>in</strong> Betracht gezogen. Bei der Analyse wurden zwei<br />

xvi

unterschiedliche Szenarien berücksichtigt, die darauf basierten, <strong>in</strong> welcher Zeitspanne die<br />

Geflügelfarmen Strom produzieren können. Szenario I betrachtete die Stromerzeugung fünf<br />

Stunden lang <strong>in</strong> der Spitzenzeit des Landes, während Szenario II die Stromerzeugung zwölf<br />

Stunden lang betrachtete, was dem Gesamttagesverbrauch der Geflügelfarmen entspricht.<br />

Vier unterschiedliche Fälle wurden jeweils bei den Szenarien betrachtet. Beim ersten Fall<br />

wurde Strom nur als e<strong>in</strong> Produkt betrachtet, um E<strong>in</strong>nahmen zu erzielen, während beim<br />

zweiten Fall Kosten für CO2 und die Kosten für Strom als E<strong>in</strong>nahmequellen betrachtet<br />

wurden. Beim dritten Fall wurden die Kosten für Düngemittel und die Kosten für Elektrizität<br />

als E<strong>in</strong>nahmequellen betrachtet. Beim vierten Fall schließlich wurden CO2, Düngemittel und<br />

Strom zusammen als gew<strong>in</strong>nbr<strong>in</strong>gende Produkte angesehen. Alle Fälle wurden unter jedem<br />

Szenario betrachtet, um die m<strong>in</strong>imale Größe e<strong>in</strong>er Geflügelfarm zu ermitteln. Dann wurde<br />

das <strong>Potential</strong> der Stromgew<strong>in</strong>nung, auf der Grundlage von Beispieldaten im Studiengebiet,<br />

für unterschiedliche Fälle unter unterschiedlichen Szenarien geschätzt.<br />

Status des Stromverbrauchs auf Geflügelfarmen. Elektrizität ist für die Produktion der<br />

Eier und für das Wachstum der Vögel unabd<strong>in</strong>gbar. Elektrizität wird <strong>in</strong> der Industrie<br />

hauptsächlich für Lampen verwendet, um korrekte Beleuchtung <strong>in</strong> der Geflügelhalle zu<br />

erzeugen, für Ventilatoren, um die erforderliche Temperatur zu gewährleisten, im Brutkasten,<br />

um die Küken zu brüten und für die Wasserpumpen, die das Wasser liefern. Der tägliche<br />

Stromverbrauch der Geflügelfarmen beg<strong>in</strong>nt gewöhnlich 10 Uhr morgens und setzt sich bis<br />

10 Uhr abends fort. 100% der Geflügelfarmen haben e<strong>in</strong>en Lastabwurf von ca. 4 Stunden pro<br />

Tag, meistens am Abend. Nur 30% der Farmen haben e<strong>in</strong>e Ausweichanlage für den Fall e<strong>in</strong>es<br />

Stromausfalls, die restlichen 70% verfügen über ke<strong>in</strong>erlei Sicherungssystem. Biogas, das auf<br />

den unterschiedlichen Geflügelfarmen produziert wird, wird hauptsächlich für das Kochen im<br />

Haushalt verwendet. Nur e<strong>in</strong>e sehr ger<strong>in</strong>e Anzahl von Geflügelfarmen im Gazipur Bezirk<br />

sowie im gesamten Land benutzt Biogas sowohl für Wärmeerzeugung als auch zur<br />

Stromerzeugung. Ungefähr 38% der Farmen können ihr Biogas an m<strong>in</strong>destens e<strong>in</strong>en Kunden<br />

verkaufen, der Rest von 62% hat ke<strong>in</strong>en Markt, um es zu verkaufen. Daher könnte die<br />

Erzeugung von Strom e<strong>in</strong>e Methode se<strong>in</strong>, das Biogas <strong>in</strong> geeigneter Weise zu verwenden.<br />

Nur auf 8% der Farmen wird Flüssigmist als Düngemittel benutzt, während die restlichen<br />

92% der Landwirte Flüssigmist nicht als Düngemittel verwenden, da ihnen das Wissen über<br />

den Nutzen fehlt. Gleichzeitig verbietet das geltende Recht den Landwirten, den Flüssigmist<br />

ohne Patent zu verkaufen. Z.Z. gibt es daher ke<strong>in</strong>en Markt für Flüssigmist. Jedoch verkaufen<br />

wenige große Farmen Flüssigmist als Düngemittel mit Patent.<br />

xvii

Gegenwärtiger Status der Stromerzeugung durch Geflügeldung. Stromerzeugung ist<br />

relativ neu <strong>in</strong> Bangladesch. In den unterschiedlichen Geflügelfarmen des Landes werden<br />

verschiedene Technologien verwendet. Die gebräuchlichste ist die Verwendung e<strong>in</strong>es<br />

Erdgasgenerators, der Biogas als Treibst<strong>of</strong>f verwendet. Die meisten Farmen, die Strom durch<br />

Geflügeldung gew<strong>in</strong>nen, haben ke<strong>in</strong>e H2S-Abfuhr. H2S ist gegenüber allen Metallen streng<br />

ätzend, die mit dem Transport der Gas- und Metallteile e<strong>in</strong>er Masch<strong>in</strong>e verbunden s<strong>in</strong>d, die<br />

durch e<strong>in</strong> solches Gas, das H2S enthält, angetrieben wird. Um die mit H2S verbundenen<br />

Probleme zu überw<strong>in</strong>den, hat GTZ Bangladesch e<strong>in</strong> Flaggschiffprojekt auf der Raj Geflügel-<br />

Farm im Faridpur Bezirk <strong>in</strong>s Leben gerufen, das wissenschaftlicher ist als jede mögliche<br />

andere Technologie, die z.Z. verwendet wird.<br />

F<strong>in</strong>azielle Analyse. Auf der Grundlage von unterschiedliche Annahmen, wurden NPV, IRR<br />

und Amortisationsdauer für Geflügelfarmen mit den Größen von 500, 1000, 2000, 3000,<br />

4000, 5000, 6000, 7000, 8000, 9000, 10000, 15000, 20000 und 50000 Vögeln errechnet. Der<br />

Diskontsatz wurde bei 8% betrachtet und die Lebensdauer des Projektes wurde auf 20 Jahre<br />

festgesetzt. NPV, IRR und Amortisationsdauer wurden für jede Größe von Geflügelfarmen<br />

unter den Szenarien I und II für vier unterschiedliche Fälle errechnet. Die Berechnung wurde<br />

durchgeführt, um die m<strong>in</strong>imale Größe für Geflügelfarmen, die Elektrizität mit f<strong>in</strong>anzieller<br />

Rentabilität erzeugen können, herauszuf<strong>in</strong>den. Es wurde festgestellt, dass Geflügelfarmen,<br />

mit 500 Vögeln bis zu 50.000 Vögeln alle e<strong>in</strong>em negativen NPV und niedrigeren IRR<br />

gegenüberstehen, als der Diskontsatz sowie e<strong>in</strong>e sehr hohe Amortisationsdauer <strong>in</strong> dem Falle,<br />

dass Elektrizität als alle<strong>in</strong>ige E<strong>in</strong>kommensquellle angesehen wird. Auch wenn es CO2– und<br />

Elektrizitätse<strong>in</strong>nahmen gibt, ist nicht jede Größe von Geflügelfarmen f<strong>in</strong>anziell<br />

kostendeckend, wie im Szenario I, wo täglich 5 Stunden Elektrizität pro Tag erzeugt wird. Im<br />

Szenario II h<strong>in</strong>gegen, wo Elektrizität für zwölf Stunden pro Tag produziert wird, s<strong>in</strong>d die<br />

Farmen dann f<strong>in</strong>anziell kostendeckend, wenn Sie e<strong>in</strong>e Kapazität von 6000 Vögeln und mehr<br />

aufweisen. Werden anstelle des CO2 Gew<strong>in</strong>ne durch Düngemittel und Strom erzielt, muss mit<br />

m<strong>in</strong>destens 1000 Vögeln und mehr gewirtschaftet werden. In diesem Fall konnte das NPV als<br />

positiv erachtet werden; das IRR ist höher als der Diskontsatz und der Rückzahlungszeitraum<br />

ist wesentlich ger<strong>in</strong>ger als die Projektlebensdauer. Letztendlich arbeiten Farmen, die CO2 –,<br />

Düngemittel- und Elektrizitätse<strong>in</strong>nahmen haben dann kostendeckend, wenn Sie e<strong>in</strong>e<br />

Kapazität von 1000 Vögeln und mehr haben. Bei Farmen, die e<strong>in</strong>e Kapazität von 500 Vögeln<br />

haben, ist der NPV jedoch negativ und das IRR ger<strong>in</strong>ger als der Diskontsatz, selbst wenn man<br />

das CO2, Düngemittel und Elektrizität als E<strong>in</strong>nahmequellen betrachtet.<br />

xviii

Es besteht ke<strong>in</strong> wirtschaftliches <strong>Potential</strong>, sowohl im Studiengebiet als auch im Rest des<br />

Landes, um Elektrizität durch Geflügeldung zu erzeugen, wenn nur die daraus resultierende<br />

Stromerzeugung als E<strong>in</strong>kommensquelle dient. Das geschätzte <strong>Potential</strong> der<br />

Elektrizitätserzeugung entspricht etwa 13 GWh im Gazipur Bereich und 135 GWh im<br />

gesamten Land pro Jahr, wenn die CO2--E<strong>in</strong>nahmen zu den Elektrizitätse<strong>in</strong>nahmen<br />

dazugerechnet werden. Dabei wird vorausgesetzt, dass 12 Stunden/Tag für den<br />

Gesamtverbrauch der Farm produziert wird.<br />

Wenn jedoch nur 5 Stunden/Tag Energie während der Spitzendstunden des Landes erzeugt<br />

wird, besteht ke<strong>in</strong> wirtschaftliches <strong>Potential</strong>. Das geschätzte maximale <strong>Potential</strong> der<br />

Elektrizitätserzeugung im Gazipur Bereich entspricht 34 GWh/Jahr und 360 GWh im<br />

gesamten Land pro Jahr, wenn entsprechend die E<strong>in</strong>nahmen für Düngemittel zu den<br />

Elektrizitätse<strong>in</strong>nahmen dazugerechnet werden, unabhängig von der Stundenanzahl der<br />

Stromerzeugung.<br />

Fazit. Elektrizität aus Geflügeldung zu gew<strong>in</strong>nen, stellt e<strong>in</strong> <strong>Potential</strong> dar. Seitens der<br />

Landwirte besteht e<strong>in</strong> hohes Interesse an dieser Form der Stromerzeugung. Dieses Interesse<br />

besteht aufgrund der Tatsache, daß alle Geflügelfarmen während des Tages, meistens am<br />

Abend, e<strong>in</strong>en Lastabwurf haben, was die Produktion der Farm hemmt. Die gewonnene<br />

Elektrizität aus Geflügeldung kann den Gesamttagesverbrauch der meisten Geflügelfarmen<br />

decken. Zusätzlich kann Elektrizität auch nur für die Spitzenzeiten produziert werden, was<br />

die Farmen vor e<strong>in</strong>em Stromausfall bewahrt. Die Stromerzeugung für zwölf Stunden pro Tag<br />

ist f<strong>in</strong>anziell kostengünstiger, als die Stromerzeugung für 5 Stunden während der<br />

Spitzenzeiten. Allerd<strong>in</strong>gs wirtschaften die Farmen nicht kostendeckend, wenn der gewonnene<br />

Strom die e<strong>in</strong>zige E<strong>in</strong>nahmequelle darstellt. Düngemittel ist das wichtigste Element, damit<br />

mit der Stromerzeugung E<strong>in</strong>nahmen erzielt werden können, denn nur so können die Farmen<br />

die Kosten, die mit der Stromgew<strong>in</strong>nung e<strong>in</strong>hergehen, decken. Um die Stromgew<strong>in</strong>nung<br />

durch Geflügeldung <strong>in</strong> den nationalen Energiemix e<strong>in</strong>zubr<strong>in</strong>gen, ist e<strong>in</strong>e Änderung des<br />

vorhandenen Gesetzes notwendig, die daraus besteht, die bürokratischen H<strong>in</strong>dernisse zu<br />

beseitigen. Außerdem muss den Menschen bewusst gemacht werden, dass Flüssigmist als<br />

Düngemittel verwendet werden kann. So kann e<strong>in</strong> Markt für dieses Produkt geschafft werden.<br />

xix

1.1 Background<br />

CHAPTER 1 INTRODUCTION<br />

<strong>The</strong> Per capita energy consumption <strong>in</strong> Bangladesh is 197 kg <strong>of</strong> oil equivalent (kgoe), which is<br />

far less than the averages for low <strong>in</strong>come (563 kgoe) countries 3 . Around 33% (Hossa<strong>in</strong> and<br />

Tamim, 2005/2006, p. 16) <strong>of</strong> the total population is covered by electricity network and 4%<br />

(ibid, p. 13) are covered under natural gas network. About 82% <strong>of</strong> total electricity comes<br />

<strong>from</strong> natural gas 4 . Lack <strong>of</strong> energy is the ma<strong>in</strong> h<strong>in</strong>der<strong>in</strong>g force for poverty alleviation. On the<br />

other hand the reserves <strong>of</strong> natural gas are runn<strong>in</strong>g out. To make the energy system <strong>of</strong> the<br />

country susta<strong>in</strong>able, search<strong>in</strong>g for alternative sources <strong>of</strong> energy is mandatory.<br />

Biogas is one <strong>of</strong> the promis<strong>in</strong>g renewable energy sources <strong>in</strong> Bangladesh. Different sources <strong>of</strong><br />

biogas <strong>in</strong> the country are cattle dung, poultry dropp<strong>in</strong>g, crop residue, kitchen waste etc.<br />

Bangladesh has a promis<strong>in</strong>g poultry <strong>in</strong>dustry to meet up the prote<strong>in</strong> need <strong>of</strong> the people.<br />

Commercial poultry farms <strong>in</strong> Bangladesh are grow<strong>in</strong>g at a rate <strong>of</strong> 7% per year s<strong>in</strong>ce 2001-<br />

2002 5 and the number <strong>of</strong> birds <strong>in</strong> the poultry farms is grow<strong>in</strong>g at 5.59% per year s<strong>in</strong>ce 2000-<br />

2001 (ibid). <strong>The</strong>re were about 130 thousand poultry farms <strong>in</strong> the country <strong>in</strong> 2005-2006 6 . <strong>The</strong><br />

number <strong>of</strong> birds <strong>in</strong> poultry farms was about 194.82 million <strong>in</strong> 2005-2006 (ibid). <strong>The</strong>oretically<br />

<strong>from</strong> these poultry farms about 19482 tonnes <strong>of</strong> chicken’s dropp<strong>in</strong>gs can be produced every<br />

day. <strong>The</strong>re are two types <strong>of</strong> poultry farms <strong>in</strong> the country and these are; layer farms and broiler<br />

farms. <strong>The</strong> dropp<strong>in</strong>gs <strong>from</strong> broiler farms are not used for biogas generation <strong>in</strong> the country due<br />

to the nature <strong>of</strong> rear<strong>in</strong>g the broiler birds which produces dropp<strong>in</strong>gs <strong>in</strong> batch not cont<strong>in</strong>uous.<br />

However, the dropp<strong>in</strong>gs <strong>from</strong> broiler farms can be used to produce electricity by <strong>in</strong>c<strong>in</strong>eration<br />

technology. Biogas can be produced <strong>from</strong> the layer poultry dropp<strong>in</strong>gs through digester<br />

technology. <strong>The</strong> total amount <strong>of</strong> biogas that can be produced <strong>from</strong> poultry dropp<strong>in</strong>g <strong>in</strong> the<br />

country is about 753046 m 3 per day 7 . At present, biogas is used mostly for thermal purposes<br />

especially for household cook<strong>in</strong>g and very few for electricity production. <strong>The</strong> total amount <strong>of</strong><br />

3<br />

http://www.acdis.uiuc.edu/Research/OPs/Samr<strong>in</strong>a/contents/part1.html, pr<strong>in</strong>ted on 18.08.2007<br />

4<br />

http://www.bpdb.gov.bd/<strong>in</strong>stalled_fuel.htm, pr<strong>in</strong>ted on 20.08.2007<br />

5<br />

own calculation based on data provided by Mr. A. S. Md. Abdul Hannan, Scientific Officer, Department <strong>of</strong><br />

Livestock Services (DLS), Dhaka-1215, Bangladesh, 17.05.2007<br />

6<br />

Data provided by Mr. A. S. Md. Abdul Hannan, Scientific Officer, Department <strong>of</strong> Livestock Services (DLS),<br />

Dhaka-1215, Bangladesh, 17.05.2007<br />

7<br />

own calculation based on data provided by Mr. A. S. Md. Abdul Hannan, Scientific Officer, Department <strong>of</strong><br />

Livestock Services (DLS), Dhaka-1215, Bangladesh, 17.05.2007 and data provided by Mr. Md. Kafiludd<strong>in</strong><br />

Bhuyan, District Livestock Officer, Gazipur, 13.05.2007<br />

1

electricity that could be produced <strong>from</strong> the poultry farms through digester technology is about<br />

1000 MWh per day (ibid).<br />

Recently, the government, non government organizations and private entrepreneurs have<br />

<strong>in</strong>stalled small scale gas generators <strong>in</strong> some poultry farms to produce electricity. For<br />

example, Local Government Eng<strong>in</strong>eer<strong>in</strong>g Department (LGED) <strong>of</strong> Bangladesh has <strong>in</strong>stalled an<br />

electricity generation unit <strong>from</strong> poultry waste at Faridpur Muslim Mission which serves the<br />

farm’s own electricity demand dur<strong>in</strong>g power cut. On the other hand, Bogra <strong>Poultry</strong> Complex<br />

itself has <strong>in</strong>stalled a system to produce electricity <strong>from</strong> poultry waste to meet the farms own<br />

electricity demand through out the day. <strong>The</strong> biogas produced <strong>from</strong> the poultry waste is us<strong>in</strong>g<br />

to generate electricity mostly by natural gas generator.<br />

<strong>The</strong> poultry farms <strong>in</strong> the country are fac<strong>in</strong>g enormous power shortage every day which<br />

hampers the production <strong>of</strong> the <strong>in</strong>dustry. Dissem<strong>in</strong>ation <strong>of</strong> the technology could meet the<br />

poultry sector’s electricity demand as well as the need <strong>of</strong> adjacent households. This can<br />

reduce the burden on national electricity grid and contribute to the national economy as well.<br />

1.2 Objective <strong>of</strong> the Study<br />

<strong>The</strong> ma<strong>in</strong> objective <strong>of</strong> the study is to identify the economic potential <strong>of</strong> electricity generation<br />

<strong>from</strong> poultry waste <strong>in</strong> commercial poultry sector <strong>in</strong> Bangladesh.<br />

Specific objective:<br />

1. To estimate the amount <strong>of</strong> electricity which can be produced if only electricity is<br />

considered as a product to earn revenue under different scenarios.<br />

2. To estimate the amount <strong>of</strong> electricity which can be produced if CO2 and electricity are<br />

considered as a product to earn revenue under different scenarios.<br />

3. To estimate the amount <strong>of</strong> electricity which can be produced if fertilizer and<br />

electricity are considered as a product to earn revenue under different scenarios?<br />

4. To estimate the amount <strong>of</strong> electricity which can be produced if CO2, fertilizer and<br />

electricity are considered as a product to earn revenue under different scenarios.<br />

2

1.3 Research Question<br />

To satisfy the above specific objectives, the study <strong>in</strong>tends to <strong>in</strong>vestigate the follow<strong>in</strong>g<br />

research questions;<br />

1. What is the energy consumption pattern and energy needs <strong>in</strong> poultry farms?<br />

2. What k<strong>in</strong>d <strong>of</strong> technology is presently used to produce electricity <strong>from</strong> poultry waste <strong>in</strong><br />

the country?<br />

<strong>The</strong> above two questions correspond to all the specific objectives.<br />

3. What is the m<strong>in</strong>imum poultry farm size that is economically viable to produce<br />

electricity if only electricity is considered as a product to earn revenue under different<br />

scenarios?<br />

<strong>The</strong> above question corresponds to the first specific objective.<br />

4. What is the m<strong>in</strong>imum poultry farm size that is economically viable to produce<br />

electricity if CO2 and electricity is considered as a product to earn revenue under<br />

different scenarios?<br />

<strong>The</strong> above question corresponds to the second specific objective.<br />

5. What is the m<strong>in</strong>imum poultry farm size that is economically viable to produce<br />

electricity if fertilizer and electricity is considered as a product to earn revenue under<br />

different scenarios?<br />

<strong>The</strong> above question corresponds to the third specific objective.<br />

6. What is the m<strong>in</strong>imum poultry farm size that is economically viable to produce<br />

electricity if CO2, fertilizer and electricity are considered as a product to earn revenue<br />

under different scenarios?<br />

<strong>The</strong> above question corresponds to the fourth specific objective.<br />

1.4 Research Hypothesis:<br />

1. <strong>Poultry</strong> waste <strong>in</strong> commercial poultry sector as a source <strong>of</strong> biogas has substantial<br />

potential for electricity generation.<br />

2. Produc<strong>in</strong>g electricity <strong>from</strong> poultry waste <strong>of</strong> commercial poultry sector as a source <strong>of</strong><br />

biogas is economically feasible.<br />

3

1.5 Significance <strong>of</strong> the Study:<br />

Bangladesh is one <strong>of</strong> the least developed countries <strong>in</strong> the world and energy poverty is the<br />

ma<strong>in</strong> h<strong>in</strong>drance for poverty alleviation <strong>in</strong> the country. This study will give the policy makers<br />

a new direction to a more susta<strong>in</strong>able energy source which can reduce the energy crisis <strong>of</strong> the<br />

country significantly. This will help to reduce the dependency on fossil fuel to meet up the<br />

energy demand <strong>of</strong> the country. <strong>The</strong> study looks <strong>in</strong>to the present status <strong>of</strong> energy consumption<br />

<strong>in</strong> different poultry farms which will give the people concerned an idea to f<strong>in</strong>d a way to<br />

reduce the energy consumption <strong>in</strong> poultry sector. <strong>The</strong> study aims to identify the m<strong>in</strong>imum<br />

poultry farms size which is f<strong>in</strong>ancially feasible to produce electricity. To dissem<strong>in</strong>ate the<br />

technology it is necessary to know the m<strong>in</strong>imum size <strong>of</strong> poultry farm which are f<strong>in</strong>ancially<br />

viable. <strong>The</strong>refore, the study will help the different stakeholders to dissem<strong>in</strong>ate the technology<br />

<strong>in</strong> a susta<strong>in</strong>able manner. <strong>The</strong> study also estimates the total potential <strong>of</strong> electricity that could<br />

be generated <strong>from</strong> poultry waste. This will help the public and private sector <strong>in</strong>vestors to take<br />

decision <strong>in</strong> <strong>in</strong>vest<strong>in</strong>g for electricity generation <strong>from</strong> poultry waste.<br />

1.6 Overview <strong>of</strong> the Chapters<br />

This report is divided <strong>in</strong>to seven chapters. Each chapter is further divided <strong>in</strong>to sub chapters to<br />

look at the subject matter <strong>in</strong> depth. <strong>The</strong> first chapter describes an <strong>in</strong>troductory background <strong>of</strong><br />

the study, significance <strong>of</strong> the study, research questions and ma<strong>in</strong> objectives <strong>of</strong> the study.<br />

Second chapter provides the background <strong>in</strong>formation <strong>of</strong> the country as well as the study area<br />

relevant to the study such as energy sector <strong>in</strong> the country, energy policy issues, poultry sector<br />

etc. and some general features. Third chapter discusses the methodology <strong>of</strong> the study which<br />

<strong>in</strong>cludes the approach <strong>of</strong> the study, data collection, data analysis, different scenario methods<br />

and scope and limitation <strong>of</strong> the study. Fourth chapter gives a detail analysis <strong>of</strong> the energy<br />

consumption status <strong>in</strong> poultry farms. Fifth chapter describes the present status <strong>of</strong> electricity<br />

generation <strong>from</strong> poultry waste <strong>in</strong> the country. Sixth chapter describes an <strong>in</strong> depth analysis <strong>of</strong><br />

the potential <strong>of</strong> electricity generation <strong>from</strong> poultry waste <strong>in</strong> the country as well as <strong>in</strong> the study<br />

area. F<strong>in</strong>ally, chapter seven concludes the f<strong>in</strong>d<strong>in</strong>gs <strong>of</strong> the study and proposes some<br />

recommendations based upon the f<strong>in</strong>d<strong>in</strong>gs.<br />

4

CHAPTER 2 BACKGROUND INFORMATION<br />

2.1 Country Background<br />

2.1.1 General Overview<br />

Geographically, Bangladesh lies <strong>in</strong> the north eastern part <strong>of</strong> South Asia between 20º34´ and<br />

26º38´ north latitude and 88º01’ and 92º41’ east longitude (BBS, 2007, p. XIX). Bangladesh<br />

is surrounded by India on west, north and north-east and Myanmar on the south-east and the<br />

Bay <strong>of</strong> Bengal on the south (ibid). <strong>The</strong> total land area <strong>of</strong> the country is 56,977 square miles or<br />

1,47,570 square kilometer (sq km) (ibid). <strong>The</strong> map <strong>of</strong> the country is given <strong>in</strong> figure 2.1. <strong>The</strong><br />

climate <strong>of</strong> Bangladesh is sub-tropical monsoon climate. In w<strong>in</strong>ter the temperature ranges<br />

<strong>from</strong> a m<strong>in</strong>imum <strong>of</strong> 7.22º C -12.77º C to maximum <strong>of</strong> 23.88º C -31.11º C. <strong>The</strong> maximum<br />

temperature <strong>of</strong> the country recorded <strong>in</strong> summer <strong>from</strong> 36.66º C to 40.55º C (ibid, p. XX).<br />

<strong>The</strong> enumerated population <strong>of</strong> the country is currently 123.8 million (accord<strong>in</strong>g to the<br />

population census 2001). (BBS, 2007, p. XIX-XX). Out <strong>of</strong> which the percentage <strong>of</strong> rural<br />

population is 80.2% and the rest 19.8 % is urban population (ibid, p.32-33 and own<br />

calculation ). <strong>The</strong> <strong>in</strong>ter-censal growth rate <strong>of</strong> population <strong>in</strong> 2001 was 1.48% per annum. (ibid,<br />

p.33) <strong>The</strong> density <strong>of</strong> population is 839 per sq km (ibid, p. XIX-XX and own calculation). <strong>The</strong><br />

literacy rate <strong>in</strong> the country is 45.3% for population 7 years or above (ibid, p. XIX-XX).<br />

Bangladesh has six adm<strong>in</strong>istrative divisions (ibid, p. XXI). <strong>The</strong>se divisions are subdivided<br />

<strong>in</strong>to district or zilla (ibid). <strong>The</strong> total number <strong>of</strong> district or zilla <strong>in</strong> the country is 64 (ibid). Each<br />

district or zilla is further sub-divided <strong>in</strong>to upazila or thana. (ibid).<br />

In 2004-2005 the per capita GDP <strong>of</strong> the country at current market prices was 27061 BDT or<br />

US$ 440 (1 US$= 61.39 BDT, ibid, p.418) approximately.<br />

5

Figure 2.1 Show<strong>in</strong>g the Geography <strong>of</strong> Bangladesh<br />

Source: www.un.org/Depts/Cartographic/map/pr<strong>of</strong>ile/banglade.pdf pr<strong>in</strong>ted on 04.06.07<br />

6<br />

Gazipur<br />

District

2.1.2 Energy Sector <strong>in</strong> Bangladesh<br />

Primary Commercial Energy Resources<br />

About 60% <strong>of</strong> the total primary energy <strong>in</strong> the country comes <strong>from</strong> commercial energy sources<br />

(NEP, 2006, p. 1).<strong>The</strong> primary commercial energy resources <strong>in</strong> Bangladesh are natural gas<br />

and recently discovered coal. <strong>The</strong> recoverable proven and probable natural gas reserve <strong>in</strong> the<br />

country is 20.51 Trillion Cubic Feet (TCF) and the cumulative production up to June, 2004<br />

was 5.90 TCF (BBS, 2007, p. 244). <strong>The</strong> total gas consumption <strong>in</strong> 1999-00 and 2004-05 was<br />

8780 MMCF and 12922 MMCF respectively (BBS, 2007, p. 251). <strong>The</strong> average growth <strong>of</strong> gas<br />

consumption <strong>in</strong> the last six years is 7.86%. (ibid and own calculation) With this average<br />

growth <strong>of</strong> consumption the reserve <strong>of</strong> natural gas could susta<strong>in</strong> the country up to the year<br />

2020 without any discovery <strong>of</strong> new gas fields (BBS, 2007, p. 244, 246, 251 and own<br />

calculation). Natural gas is used both as primary and secondary fuel <strong>in</strong> the energy mix <strong>of</strong> the<br />

country. Figure 2.2 shows the consumption <strong>of</strong> natural gas <strong>in</strong> different sectors.<br />

<strong>in</strong> MMCM<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

Figure 2.2 Consumption <strong>of</strong> natural gas by category <strong>of</strong> sectors<br />

3976<br />

2661<br />

1463<br />

7<br />

137<br />

1486<br />

1199<br />

Power Fertilizer Industrial Commercial Domestic Others<br />

Sector<br />

Source: BBS, 2007, p. 246 and own plott<strong>in</strong>g<br />

<strong>The</strong> proven coal reserve <strong>in</strong> Bangladesh is estimated at over 1 billion tons which is equivalent<br />

to 38 TCF <strong>of</strong> natural gas which is more than three times the rema<strong>in</strong><strong>in</strong>g proven and probable<br />

gas reserve <strong>in</strong> the country (NEP, 2006, p. 15).

Power Sector<br />

<strong>The</strong> total <strong>in</strong>stalled capacity <strong>of</strong> electricity generation <strong>in</strong> Bangladesh is 5245 MW 8 . Currently<br />

the country is fac<strong>in</strong>g enormous electricity deficit. <strong>The</strong> amount <strong>of</strong> load shedd<strong>in</strong>g is 572 MW<br />

aga<strong>in</strong>st a maximum load <strong>of</strong> 3548 MW as on 03.06.2007 9 . Natural gas is the prime source <strong>of</strong><br />

primary energy <strong>in</strong> electricity generation followed by furnace oil. Figure 2.3 shows the<br />

<strong>in</strong>stalled capacity <strong>of</strong> electricity generation by type <strong>of</strong> fuel.<br />

4.08%<br />

Figure 2.3 Total Installed Capacity by Type <strong>of</strong> Fuel<br />

5.34% 4.39% 4.77%<br />

Total 5245 MW<br />

8<br />

81.84%<br />

Gas<br />

Diesel<br />

Furnace oil<br />

Hydro<br />

Source: http://www.bpdb.gov.bd/<strong>in</strong>stalled_fuel.htm pr<strong>in</strong>ted on 20.08.2007<br />

F<strong>in</strong>al Consumption <strong>of</strong> Commercial Energy<br />

Commercial energy <strong>in</strong>cludes natural gas, electricity, petroleum products and coal (BBS,<br />

2007, p. 252). <strong>The</strong> commercial energy consumed by different sectors is shown <strong>in</strong> Figure 2.4.<br />

<strong>The</strong> total f<strong>in</strong>al energy consumption was 33416 thousand tons <strong>of</strong> coal equivalents (TCE) <strong>in</strong><br />

2003-04 (ibid). <strong>The</strong> share <strong>of</strong> consumption <strong>of</strong> f<strong>in</strong>al commercial energy <strong>in</strong> different sectors are<br />

as follows: domestic 17.43%, <strong>in</strong>dustrial 9.83%, commercial 0.95%, transport 23.70%,<br />

agriculture & others 12.45% and non energy use ( use as a raw material for fertilizer<br />

production) 35.63%. (ibid and own calculation)<br />

8 http://www.bpdb.gov.bd/key_statistics.htm pr<strong>in</strong>ted on 20.08.2007<br />

9 http://www.bpdb.gov.bd/download/Daily_Summery_Report.pdf pr<strong>in</strong>ted on 20.08.2007<br />

Coal

'000' tons <strong>of</strong> coal equivalent<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

0<br />

Figure 2.4 Sector wise F<strong>in</strong>al Consumption <strong>of</strong> Commercial Energy<br />

5826<br />

Demestic/<br />

Residential<br />

Traditional Fuel Supply<br />

3286<br />

317<br />

Industrial Commercial/<br />

Services<br />

9<br />

Sector<br />

7921<br />

4160<br />

Transport Agriculture &<br />

Others<br />

11906<br />

Non-energy<br />

use<br />

Source: BBS, 2007, p. 252 and own plott<strong>in</strong>g<br />

About 40% <strong>of</strong> the total primary energy <strong>of</strong> the country comes <strong>from</strong> renewable energy, ma<strong>in</strong>ly<br />

biomass (NEP, 2006, p. 1). <strong>The</strong> total amount <strong>of</strong> energy supplied by traditional biomass fuel <strong>in</strong><br />