Technical Documentation Pressure Independent Characterized ...

Technical Documentation Pressure Independent Characterized ...

Technical Documentation Pressure Independent Characterized ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J20728 - 04/07 - Subject to change. © Belimo Aircontrols (USA), Inc.<br />

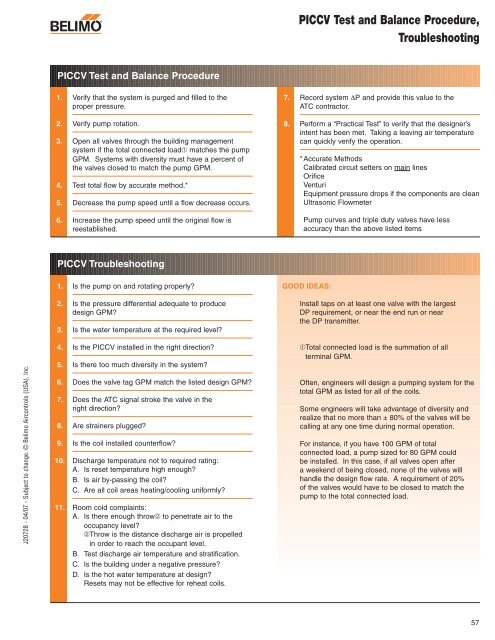

1. Verify that the system is purged and filled to the<br />

proper pressure.<br />

2. Verify pump rotation.<br />

® PICCV<br />

PICCV Test and Balance Procedure<br />

3. Open all valves through the building management<br />

system if the total connected load➀ matches the pump<br />

GPM. Systems with diversity must have a percent of<br />

the valves closed to match the pump GPM.<br />

4. Test total flow by accurate method.*<br />

5. Decrease the pump speed until a flow decrease occurs.<br />

6. Increase the pump speed until the original flow is<br />

reestablished.<br />

PICCV Troubleshooting<br />

1. Is the pump on and rotating properly?<br />

2. Is the pressure differential adequate to produce<br />

design GPM?<br />

3. Is the water temperature at the required level?<br />

4. Is the PICCV installed in the right direction?<br />

5. Is there too much diversity in the system?<br />

6. Does the valve tag GPM match the listed design GPM?<br />

7. Does the ATC signal stroke the valve in the<br />

right direction?<br />

8. Are strainers plugged?<br />

9. Is the coil installed counterflow?<br />

10. Discharge temperature not to required rating:<br />

A. Is reset temperature high enough?<br />

B. Is air by-passing the coil?<br />

C. Are all coil areas heating/cooling uniformly?<br />

11. Room cold complaints:<br />

A. Is there enough throw➁ to penetrate air to the<br />

occupancy level?<br />

➁Throw is the distance discharge air is propelled<br />

in order to reach the occupant level.<br />

B. Test discharge air temperature and stratification.<br />

C. Is the building under a negative pressure?<br />

D. Is the hot water temperature at design?<br />

Resets may not be effective for reheat coils.<br />

Test and Balance Procedure,<br />

Troubleshooting<br />

7. Record system ΔP and provide this value to the<br />

ATC contractor.<br />

8. Perform a “Practical Test” to verify that the designer’s<br />

intent has been met. Taking a leaving air temperature<br />

can quickly verify the operation.<br />

*Accurate Methods<br />

Calibrated circuit setters on main lines<br />

Orifice<br />

Venturi<br />

Equipment pressure drops if the components are clean<br />

Ultrasonic Flowmeter<br />

Pump curves and triple duty valves have less<br />

accuracy than the above listed items<br />

GOOD IDEAS:<br />

Install taps on at least one valve with the largest<br />

DP requirement, or near the end run or near<br />

the DP transmitter.<br />

➀Total connected load is the summation of all<br />

terminal GPM.<br />

Often, engineers will design a pumping system for the<br />

total GPM as listed for all of the coils.<br />

Some engineers will take advantage of diversity and<br />

realize that no more than ± 80% of the valves will be<br />

calling at any one time during normal operation.<br />

For instance, if you have 100 GPM of total<br />

connected load, a pump sized for 80 GPM could<br />

be installed. In this case, if all valves open after<br />

a weekend of being closed, none of the valves will<br />

handle the design flow rate. A requirement of 20%<br />

of the valves would have to be closed to match the<br />

pump to the total connected load.<br />

57