Technical Documentation Pressure Independent Characterized ...

Technical Documentation Pressure Independent Characterized ...

Technical Documentation Pressure Independent Characterized ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J20728 - 04/07 - Subject to change. © Belimo Aircontrols (USA), Inc.<br />

2.16 CONTROL VALVES<br />

®<br />

A. Control Valves: Factory fabricated of type, body<br />

material, and pressure class based on maximum<br />

pressure and temperature rating of the piping<br />

system, unless otherwise indicated.<br />

B. <strong>Pressure</strong> <strong>Independent</strong> Control Valves<br />

a. Manufacturers:<br />

i. BELIMO AIRCONTROLS (USA), INC.<br />

b. The modulating control valves shall be<br />

pressure independent.<br />

c. The control valves shall accurately control the flow<br />

from 0 to 100% full rated flow with an equal<br />

percentage flow characteristic. The flow shall not<br />

vary more than +/- 5% due to system pressure<br />

fluctuations across the valve with a minimum of<br />

5 PSID across the valve.<br />

d. Forged brass body rated at no less than 400 PSI,<br />

chrome plated brass ball and stem, female NPT<br />

union ends, dual EPDM lubricated O-rings and<br />

TEFZEL characterizing disc.<br />

e. Combination of actuator and valve shall provide a<br />

minimum close-off pressure rating of 200 PSID.<br />

f. The control valve shall require no maintenance<br />

and shall not include replaceable cartridges.<br />

g. All actuators shall be electronically programmed<br />

by use of a handheld programming device or<br />

external computer software. Programming using<br />

actuator mounted switches or multi-turn actuators<br />

are NOT acceptable. [Actuators for 3-wire<br />

floating (tri-state) on 1/2” – 1” pressure<br />

independent control valves shall fail in place<br />

and have a mechanical device inserted<br />

between the valve and the actuator for the<br />

adjustment of flow.] [Actuators for two-position<br />

1/2” – 1” pressure independent control<br />

valves shall fail in place and have a mechanical<br />

device inserted between the valve and the<br />

actuator for the adjustment of flow.] [Actuators<br />

shall be provided with an auxiliary switch to<br />

prove valve position.]<br />

h. The actuator shall be of the same manufacturer<br />

as the valve, integrally mounted to the valve at the<br />

factory via a single screw on a four-way DIN<br />

mounting-base.<br />

i. The control valve shall require no maintenance<br />

and shall not include replaceable cartridges.<br />

j. The manufacturer shall warrant all components<br />

for a period 5 years from the date of production,<br />

with the first two years unconditional.<br />

k. The use of pressure independent valves piped in<br />

parallel to achieve the rated coil flow shall be<br />

permitted. Actuators shall be electronically<br />

programmed to permit sequencing the flow with a<br />

single control output point. The use of external<br />

devices to permit sequencing is NOT acceptable.<br />

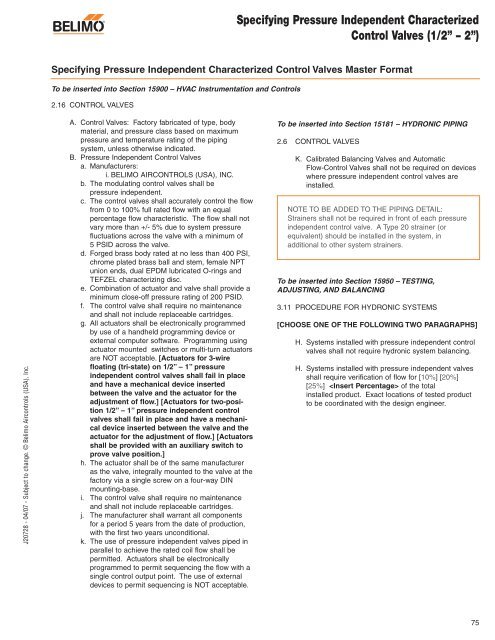

Specifying <strong>Pressure</strong> <strong>Independent</strong> <strong>Characterized</strong><br />

Control Valves (1/2” – 2”)<br />

Specifying <strong>Pressure</strong> <strong>Independent</strong> <strong>Characterized</strong> Control Valves Master Format<br />

To be inserted into Section 15900 – HVAC Instrumentation and Controls<br />

To be inserted into Section 15181 – HYDRONIC PIPING<br />

2.6 CONTROL VALVES<br />

K. Calibrated Balancing Valves and Automatic<br />

Flow-Control Valves shall not be required on devices<br />

where pressure independent control valves are<br />

installed.<br />

NOTE TO BE ADDED TO THE PIPING DETAIL:<br />

Strainers shall not be required in front of each pressure<br />

independent control valve. A Type 20 strainer (or<br />

equivalent) should be installed in the system, in<br />

additional to other system strainers.<br />

To be inserted into Section 15950 – TESTING,<br />

ADJUSTING, AND BALANCING<br />

3.11 PROCEDURE FOR HYDRONIC SYSTEMS<br />

[CHOOSE ONE OF THE FOLLOWING TWO PARAGRAPHS]<br />

H. Systems installed with pressure independent control<br />

valves shall not require hydronic system balancing.<br />

H. Systems installed with pressure independent valves<br />

shall require verification of flow for [10%] [20%]<br />

[25%] of the total<br />

installed product. Exact locations of tested product<br />

to be coordinated with the design engineer.<br />

75