Threads and Threading - Sportpilot.info

Threads and Threading - Sportpilot.info

Threads and Threading - Sportpilot.info

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

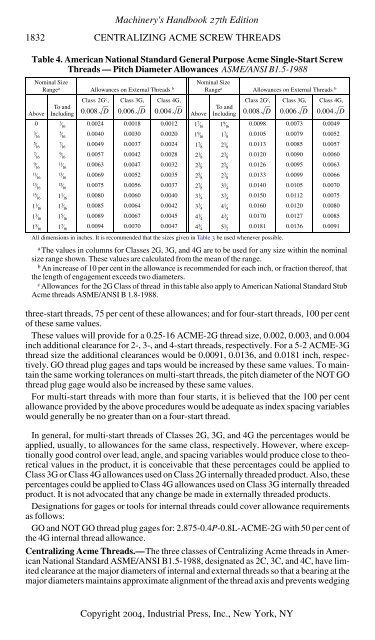

1832 CENTRALIZING ACME SCREW THREADS<br />

Table 4. American National St<strong>and</strong>ard General Purpose Acme Single-Start Screw<br />

<strong>Threads</strong> — Pitch Diameter Allowances ASME/ANSI B1.5-1988<br />

Nominal Size<br />

Range a Allowances on External <strong>Threads</strong> b<br />

Machinery's H<strong>and</strong>book 27th Edition<br />

Nominal Size<br />

Rangea Allowances on External <strong>Threads</strong> b<br />

Class 2G<br />

Above<br />

To <strong>and</strong><br />

Including<br />

c , Class 3G, Class 4G,<br />

Class 2G<br />

Above<br />

To <strong>and</strong><br />

Including<br />

c , Class 3G, Class 4G,<br />

0 3<br />

⁄16 0.0024 0.0018 0.0012 17 ⁄ 16 19 ⁄ 16 0.0098 0.0073 0.0049<br />

3<br />

⁄16<br />

5<br />

⁄16 0.0040 0.0030 0.0020 19 ⁄ 16 17 ⁄ 8 0.0105 0.0079 0.0052<br />

5<br />

⁄16<br />

7<br />

⁄16 0.0049 0.0037 0.0024 17 ⁄ 8 21 ⁄ 8 0.0113 0.0085 0.0057<br />

7<br />

⁄16<br />

9<br />

⁄16 0.0057 0.0042 0.0028 21 ⁄ 8 23 ⁄ 8 0.0120 0.0090 0.0060<br />

9<br />

⁄16<br />

11<br />

⁄16 0.0063 0.0047 0.0032 23 ⁄ 8 25 ⁄ 8 0.0126 0.0095 0.0063<br />

11<br />

⁄16<br />

13<br />

⁄16 0.0069 0.0052 0.0035 25 ⁄ 8 27 ⁄ 8 0.0133 0.0099 0.0066<br />

13<br />

⁄16<br />

15<br />

⁄16 0.0075 0.0056 0.0037 27 ⁄ 8 31 ⁄ 4 0.0140 0.0105 0.0070<br />

15<br />

⁄16 11 ⁄ 16 0.0080 0.0060 0.0040 31 ⁄ 4 33 ⁄ 4 0.0150 0.0112 0.0075<br />

11 ⁄ 16 13 ⁄ 16 0.0085 0.0064 0.0042 33 ⁄ 4 41 ⁄ 4 0.0160 0.0120 0.0080<br />

13 ⁄ 16 15 ⁄ 16 0.0089 0.0067 0.0045 41 ⁄ 4 43 ⁄ 4 0.0170 0.0127 0.0085<br />

15 ⁄ 16 17 ⁄ 16 0.0094 0.0070 0.0047 43 ⁄ 4 51 0.008 D 0.006 D 0.004 D 0.008 D 0.006 D 0.004 D<br />

⁄ 2 0.0181 0.0136 0.0091<br />

All dimensions in inches. It is recommended that the sizes given in Table 3 be used whenever possible.<br />

a The values in columns for Classes 2G, 3G, <strong>and</strong> 4G are to be used for any size within the nominal<br />

size range shown. These values are calculated from the mean of the range.<br />

b An increase of 10 per cent in the allowance is recommended for each inch, or fraction thereof, that<br />

the length of engagement exceeds two diameters.<br />

c Allowances for the 2G Class of thread in this table also apply to American National St<strong>and</strong>ard Stub<br />

Acme threads ASME/ANSI B 1.8-1988.<br />

three-start threads, 75 per cent of these allowances; <strong>and</strong> for four-start threads, 100 per cent<br />

of these same values.<br />

These values will provide for a 0.25-16 ACME-2G thread size, 0.002, 0.003, <strong>and</strong> 0.004<br />

inch additional clearance for 2-, 3-, <strong>and</strong> 4-start threads, respectively. For a 5-2 ACME-3G<br />

thread size the additional clearances would be 0.0091, 0.0136, <strong>and</strong> 0.0181 inch, respectively.<br />

GO thread plug gages <strong>and</strong> taps would be increased by these same values. To maintain<br />

the same working tolerances on multi-start threads, the pitch diameter of the NOT GO<br />

thread plug gage would also be increased by these same values.<br />

For multi-start threads with more than four starts, it is believed that the 100 per cent<br />

allowance provided by the above procedures would be adequate as index spacing variables<br />

would generally be no greater than on a four-start thread.<br />

In general, for multi-start threads of Classes 2G, 3G, <strong>and</strong> 4G the percentages would be<br />

applied, usually, to allowances for the same class, respectively. However, where exceptionally<br />

good control over lead, angle, <strong>and</strong> spacing variables would produce close to theoretical<br />

values in the product, it is conceivable that these percentages could be applied to<br />

Class 3G or Class 4G allowances used on Class 2G internally threaded product. Also, these<br />

percentages could be applied to Class 4G allowances used on Class 3G internally threaded<br />

product. It is not advocated that any change be made in externally threaded products.<br />

Designations for gages or tools for internal threads could cover allowance requirements<br />

as follows:<br />

GO <strong>and</strong> NOT GO thread plug gages for: 2.875-0.4P-0.8L-ACME-2G with 50 per cent of<br />

the 4G internal thread allowance.<br />

Centralizing Acme <strong>Threads</strong>.—The three classes of Centralizing Acme threads in American<br />

National St<strong>and</strong>ard ASME/ANSI B1.5-1988, designated as 2C, 3C, <strong>and</strong> 4C, have limited<br />

clearance at the major diameters of internal <strong>and</strong> external threads so that a bearing at the<br />

major diameters maintains approximate alignment of the thread axis <strong>and</strong> prevents wedging<br />

Copyright 2004, Industrial Press, Inc., New York, NY