Threads and Threading - Sportpilot.info

Threads and Threading - Sportpilot.info

Threads and Threading - Sportpilot.info

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

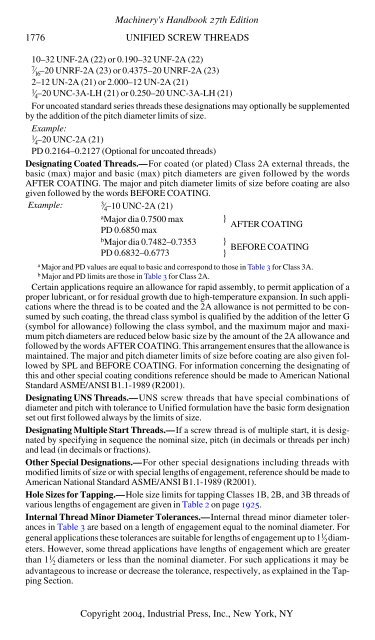

1776 UNIFIED SCREW THREADS<br />

10–32 UNF-2A (22) or 0.190–32 UNF-2A (22)<br />

7<br />

⁄16 –20 UNRF-2A (23) or 0.4375–20 UNRF-2A (23)<br />

2–12 UN-2A (21) or 2.000–12 UN-2A (21)<br />

1 ⁄4–20 UNC-3A-LH (21) or 0.250–20 UNC-3A-LH (21)<br />

For uncoated st<strong>and</strong>ard series threads these designations may optionally be supplemented<br />

by the addition of the pitch diameter limits of size.<br />

Example:<br />

1<br />

⁄4 –20 UNC-2A (21)<br />

PD 0.2164–0.2127 (Optional for uncoated threads)<br />

Designating Coated <strong>Threads</strong>.—For coated (or plated) Class 2A external threads, the<br />

basic (max) major <strong>and</strong> basic (max) pitch diameters are given followed by the words<br />

AFTER COATING. The major <strong>and</strong> pitch diameter limits of size before coating are also<br />

given followed by the words BEFORE COATING.<br />

Example:<br />

Machinery's H<strong>and</strong>book 27th Edition<br />

3 ⁄4 –10 UNC-2A (21)<br />

a Major dia 0.7500 max<br />

PD 0.6850 max<br />

b Major dia 0.7482–0.7353<br />

} AFTER COATING<br />

}<br />

BEFORE COATING<br />

PD 0.6832–0.6773 }<br />

Certain applications require an allowance for rapid assembly, to permit application of a<br />

proper lubricant, or for residual growth due to high-temperature expansion. In such applications<br />

where the thread is to be coated <strong>and</strong> the 2A allowance is not permitted to be consumed<br />

by such coating, the thread class symbol is qualified by the addition of the letter G<br />

(symbol for allowance) following the class symbol, <strong>and</strong> the maximum major <strong>and</strong> maximum<br />

pitch diameters are reduced below basic size by the amount of the 2A allowance <strong>and</strong><br />

followed by the words AFTER COATING. This arrangement ensures that the allowance is<br />

maintained. The major <strong>and</strong> pitch diameter limits of size before coating are also given followed<br />

by SPL <strong>and</strong> BEFORE COATING. For <strong>info</strong>rmation concerning the designating of<br />

this <strong>and</strong> other special coating conditions reference should be made to American National<br />

St<strong>and</strong>ard ASME/ANSI B1.1-1989 (R2001).<br />

Designating UNS <strong>Threads</strong>.—UNS screw threads that have special combinations of<br />

diameter <strong>and</strong> pitch with tolerance to Unified formulation have the basic form designation<br />

set out first followed always by the limits of size.<br />

Designating Multiple Start <strong>Threads</strong>.—If a screw thread is of multiple start, it is designated<br />

by specifying in sequence the nominal size, pitch (in decimals or threads per inch)<br />

<strong>and</strong> lead (in decimals or fractions).<br />

Other Special Designations.—For other special designations including threads with<br />

modified limits of size or with special lengths of engagement, reference should be made to<br />

American National St<strong>and</strong>ard ASME/ANSI B1.1-1989 (R2001).<br />

Hole Sizes for Tapping.—Hole size limits for tapping Classes 1B, 2B, <strong>and</strong> 3B threads of<br />

various lengths of engagement are given in Table 2 on page 1925.<br />

Internal Thread Minor Diameter Tolerances.—Internal thread minor diameter tolerances<br />

in Table 3 are based on a length of engagement equal to the nominal diameter. For<br />

general applications these tolerances are suitable for lengths of engagement up to 11 ⁄ 2 diameters.<br />

However, some thread applications have lengths of engagement which are greater<br />

than 11 a Major <strong>and</strong> PD values are equal to basic <strong>and</strong> correspond to those in Table 3 for Class 3A.<br />

b Major <strong>and</strong> PD limits are those in Table 3 for Class 2A.<br />

⁄ 2 diameters or less than the nominal diameter. For such applications it may be<br />

advantageous to increase or decrease the tolerance, respectively, as explained in the Tapping<br />

Section.<br />

Copyright 2004, Industrial Press, Inc., New York, NY