the PeoPle - OPERC - Off-highway Plant and Equipment Research ...

the PeoPle - OPERC - Off-highway Plant and Equipment Research ...

the PeoPle - OPERC - Off-highway Plant and Equipment Research ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

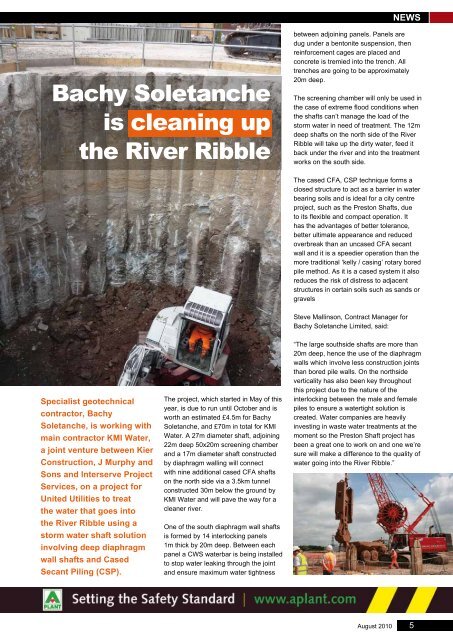

Bachy Soletanche<br />

is cleaning up<br />

<strong>the</strong> River Ribble<br />

Specialist geotechnical<br />

contractor, Bachy<br />

Soletanche, is working with<br />

main contractor KMI water,<br />

a joint venture between Kier<br />

Construction, J Murphy <strong>and</strong><br />

Sons <strong>and</strong> Interserve Project<br />

Services, on a project for<br />

United Utilities to treat<br />

<strong>the</strong> water that goes into<br />

<strong>the</strong> River Ribble using a<br />

storm water shaft solution<br />

involving deep diaphragm<br />

wall shafts <strong>and</strong> Cased<br />

Secant Piling (CSP).<br />

The project, which started in May of this<br />

year, is due to run until October <strong>and</strong> is<br />

worth an estimated £4.5m for Bachy<br />

Soletanche, <strong>and</strong> £70m in total for KMI<br />

Water. A 27m diameter shaft, adjoining<br />

22m deep 50x20m screening chamber<br />

<strong>and</strong> a 17m diameter shaft constructed<br />

by diaphragm walling will connect<br />

with nine additional cased CFA shafts<br />

on <strong>the</strong> north side via a 3.5km tunnel<br />

constructed 30m below <strong>the</strong> ground by<br />

KMI Water <strong>and</strong> will pave <strong>the</strong> way for a<br />

cleaner river.<br />

One of <strong>the</strong> south diaphragm wall shafts<br />

is formed by 14 interlocking panels<br />

1m thick by 20m deep. Between each<br />

panel a CWS waterbar is being installed<br />

to stop water leaking through <strong>the</strong> joint<br />

<strong>and</strong> ensure maximum water tightness<br />

between adjoining panels. Panels are<br />

dug under a bentonite suspension, <strong>the</strong>n<br />

reinforcement cages are placed <strong>and</strong><br />

concrete is tremied into <strong>the</strong> trench. All<br />

trenches are going to be approximately<br />

20m deep.<br />

The screening chamber will only be used in<br />

<strong>the</strong> case of extreme flood conditions when<br />

<strong>the</strong> shafts can’t manage <strong>the</strong> load of <strong>the</strong><br />

storm water in need of treatment. The 12m<br />

deep shafts on <strong>the</strong> north side of <strong>the</strong> River<br />

Ribble will take up <strong>the</strong> dirty water, feed it<br />

back under <strong>the</strong> river <strong>and</strong> into <strong>the</strong> treatment<br />

works on <strong>the</strong> south side.<br />

The cased CFA, CSP technique forms a<br />

closed structure to act as a barrier in water<br />

bearing soils <strong>and</strong> is ideal for a city centre<br />

project, such as <strong>the</strong> Preston Shafts, due<br />

to its flexible <strong>and</strong> compact operation. It<br />

has <strong>the</strong> advantages of better tolerance,<br />

better ultimate appearance <strong>and</strong> reduced<br />

overbreak than an uncased CFA secant<br />

wall <strong>and</strong> it is a speedier operation than <strong>the</strong><br />

more traditional ‘kelly / casing’ rotary bored<br />

pile method. As it is a cased system it also<br />

reduces <strong>the</strong> risk of distress to adjacent<br />

structures in certain soils such as s<strong>and</strong>s or<br />

gravels<br />

Steve Mallinson, Contract Manager for<br />

Bachy Soletanche Limited, said:<br />

“The large southside shafts are more than<br />

20m deep, hence <strong>the</strong> use of <strong>the</strong> diaphragm<br />

walls which involve less construction joints<br />

than bored pile walls. On <strong>the</strong> northside<br />

verticality has also been key throughout<br />

this project due to <strong>the</strong> nature of <strong>the</strong><br />

interlocking between <strong>the</strong> male <strong>and</strong> female<br />

piles to ensure a watertight solution is<br />

created. Water companies are heavily<br />

investing in waste water treatments at <strong>the</strong><br />

moment so <strong>the</strong> Preston Shaft project has<br />

been a great one to work on <strong>and</strong> one we’re<br />

sure will make a difference to <strong>the</strong> quality of<br />

water going into <strong>the</strong> River Ribble.”<br />

August 2010<br />

NEwS<br />

5