shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C H A P T E R T W O<br />

RESPONSE OF METALS<br />

14<br />

T I T A N I U M<br />

High Cycle Fatigue (HCF) - HCF of<br />

titanium is illustrated by Figure 2-4 that<br />

compares the capabilities of titanium<br />

alloy connecting rods for a high<br />

performance European sports car. The<br />

rods are manufactured using various<br />

processes. With <strong>shot</strong> <strong>peening</strong>, the<br />

fatigue limit was increased by<br />

approximately 20% while weight was<br />

reduced by some 40% as compared to<br />

steel connecting rods [Ref 2.12].<br />

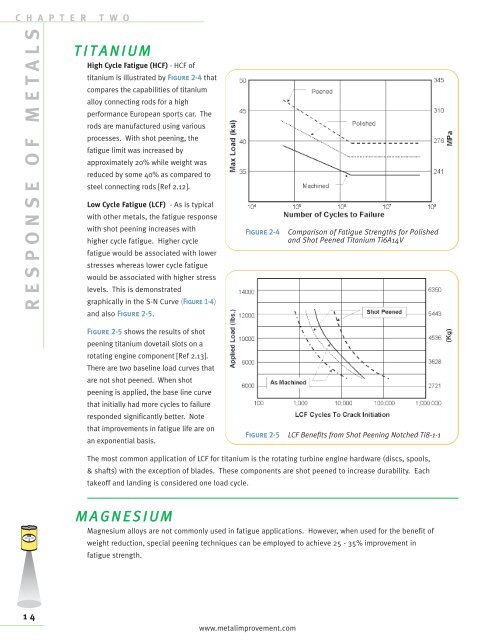

Low Cycle Fatigue (LCF) - As is typical<br />

with other metals, the fatigue response<br />

with <strong>shot</strong> <strong>peening</strong> increases with<br />

higher cycle fatigue. Higher cycle<br />

fatigue would be associated with lower<br />

<strong>stress</strong>es whereas lower cycle fatigue<br />

would be associated with higher <strong>stress</strong><br />

levels. This is demonstrated<br />

graphically in the S-N Curve (Figure 1-4)<br />

and also Figure 2-5.<br />

Figure 2-5 shows the results of <strong>shot</strong><br />

<strong>peening</strong> titanium dovetail slots on a<br />

rotating engine component [Ref 2.13].<br />

There are two baseline load curves that<br />

are not <strong>shot</strong> peened. When <strong>shot</strong><br />

<strong>peening</strong> is applied, the base line curve<br />

that initially had more cycles to failure<br />

responded significantly better. Note<br />

that improvements in fatigue life are on<br />

an exponential basis.<br />

Figure 2-4 Comparison of Fatigue Strengths for Polished<br />

and Shot Peened Titanium Ti6A14V<br />

Figure 2-5 LCF Benefits from Shot Peening Notched Ti8-1-1<br />

The most common application of LCF for titanium is the rotating turbine engine hardware (discs, spools,<br />

& shafts) with the exception of blades. These components are <strong>shot</strong> peened to increase durability. Each<br />

takeoff and landing is considered one load cycle.<br />

M A G N E S I U M<br />

Magnesium alloys are not commonly used in fatigue applications. However, when used for the benefit of<br />

weight reduction, special <strong>peening</strong> techniques can be employed to achieve 25 - 35% improvement in<br />

fatigue strength.<br />

www.metalimprovement.com