shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

C H A P T E R N I N E<br />

THERMAL F A T IGUE & HEA T EFF ECTS<br />

32<br />

E F F E C T S O F H E A T<br />

Caution should be exercised when parts are<br />

heated after <strong>shot</strong> <strong>peening</strong>. The amount of<br />

compressive <strong>stress</strong> that is relieved is a<br />

function of temperature, time and material.<br />

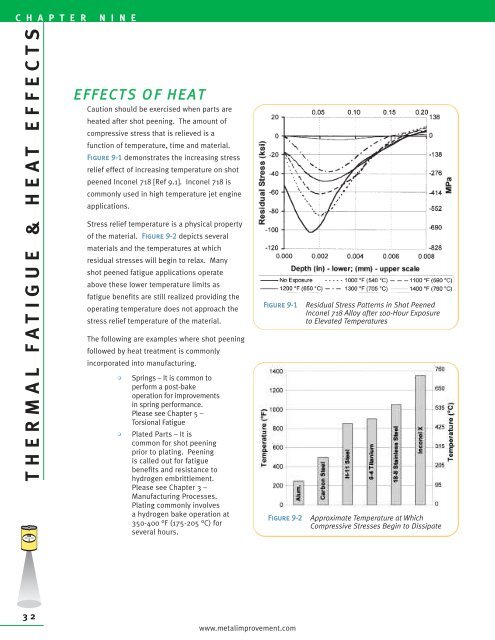

Figure 9-1 demonstrates the increasing <strong>stress</strong><br />

relief effect of increasing temperature on <strong>shot</strong><br />

peened Inconel 718 [Ref 9.1]. Inconel 718 is<br />

commonly used in high temperature jet engine<br />

applications.<br />

Stress relief temperature is a physical property<br />

of the material. Figure 9-2 depicts several<br />

materials and the temperatures at which<br />

<strong>residual</strong> <strong>stress</strong>es will begin to relax. Many<br />

<strong>shot</strong> peened fatigue applications operate<br />

above these lower temperature limits as<br />

fatigue benefits are still realized providing the<br />

operating temperature does not approach the<br />

<strong>stress</strong> relief temperature of the material.<br />

The following are examples where <strong>shot</strong> <strong>peening</strong><br />

followed by heat treatment is commonly<br />

incorporated into manufacturing.<br />

• Springs – It is common to<br />

perform a post-bake<br />

operation for improvements<br />

in spring performance.<br />

Please see Chapter 5 –<br />

Torsional Fatigue<br />

• Plated Parts – It is<br />

common for <strong>shot</strong> <strong>peening</strong><br />

prior to plating. Peening<br />

is called out for fatigue<br />

benefits and resistance to<br />

hydrogen embrittlement.<br />

Please see Chapter 3 –<br />

Manufacturing Processes.<br />

Plating commonly involves<br />

a hydrogen bake operation at<br />

350-400 °F (175-205 °C) for<br />

several hours.<br />

www.metalimprovement.com<br />

Figure 9-1 Residual Stress Patterns in Shot Peened<br />

Inconel 718 Alloy after 100-Hour Exposure<br />

to Elevated Temperatures<br />

Figure 9-2 Approximate Temperature at Which<br />

Compressive Stresses Begin to Dissipate