shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

shot peening residual stress - Metal Improvement Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

C H A P T E R T W E L V E<br />

C ONTROLL ING THE PROCESS<br />

50<br />

S P E C I F Y I N G S H O T<br />

P E E N I N G<br />

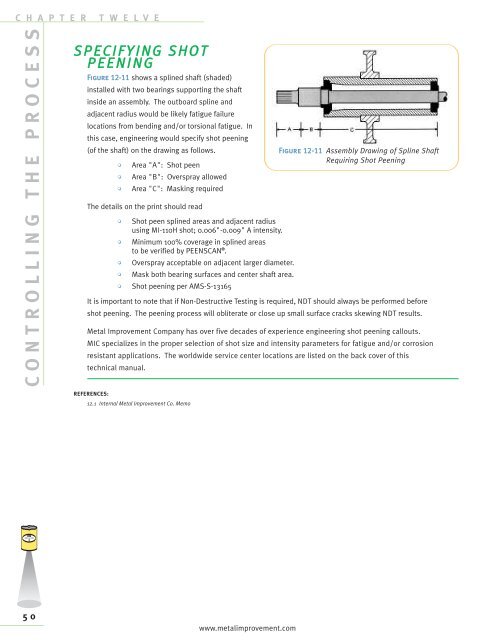

Figure 12-11 shows a splined shaft (shaded)<br />

installed with two bearings supporting the shaft<br />

inside an assembly. The outboard spline and<br />

adjacent radius would be likely fatigue failure<br />

locations from bending and/or torsional fatigue. In<br />

this case, engineering would specify <strong>shot</strong> <strong>peening</strong><br />

(of the shaft) on the drawing as follows.<br />

• Area "A": Shot peen<br />

• Area "B": Overspray allowed<br />

• Area "C": Masking required<br />

The details on the print should read<br />

• Shot peen splined areas and adjacent radius<br />

using MI-110H <strong>shot</strong>; 0.006"-0.009" A intensity.<br />

• Minimum 100% coverage in splined areas<br />

to be verified by PEENSCAN ® .<br />

• Overspray acceptable on adjacent larger diameter.<br />

• Mask both bearing surfaces and center shaft area.<br />

• Shot <strong>peening</strong> per AMS-S-13165<br />

It is important to note that if Non-Destructive Testing is required, NDT should always be performed before<br />

<strong>shot</strong> <strong>peening</strong>. The <strong>peening</strong> process will obliterate or close up small surface cracks skewing NDT results.<br />

<strong>Metal</strong> <strong>Improvement</strong> <strong>Company</strong> has over five decades of experience engineering <strong>shot</strong> <strong>peening</strong> callouts.<br />

MIC specializes in the proper selection of <strong>shot</strong> size and intensity parameters for fatigue and/or corrosion<br />

resistant applications. The worldwide service center locations are listed on the back cover of this<br />

technical manual.<br />

REFERENCES:<br />

12.1 Internal <strong>Metal</strong> <strong>Improvement</strong> Co. Memo<br />

www.metalimprovement.com<br />

Figure 12-11 Assembly Drawing of Spline Shaft<br />

Requiring Shot Peening