Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SIEMPELKAMP | FOUNDRY 18 19<br />

plaints about our parts following their installation have convinced<br />

our customers of our technical competence,” describes Dirk<br />

Howe.<br />

A top raw casting in regard to geometry and material is the<br />

basic prerequisite for a high-quality fi nished product. Prior to the<br />

actual making of each component part, it is simulated on a<br />

computer. When planning the pattern, <strong>Siempelkamp</strong> is taking<br />

unusual but successful steps in order to increase the effi ciency<br />

during production. We cast the mill heads including the<br />

trunnions, with diameters of approx. 8 m, in one piece. Heads<br />

with a larger diameter are produced in several segments (2 x<br />

180° or 4 x 90° segments) and the trunnion is produced<br />

separately. At fi rst glance, the segments seem simple, however,<br />

due to the unfavorable properties of these castings including a<br />

small wall thickness but a large area, these parts are very tricky to<br />

produce. In order to reduce costs during mechanical machining,<br />

<strong>Siempelkamp</strong> focuses on fi lling the mold quickly without<br />

turbulences, on avoiding breaking on the sand moulding edges<br />

and on minimal dross. Our successes in the area of manu facturing<br />

accuracy were a shared team effort. Indispensable in this regard<br />

are the workshops that have been developed specifi cally for this<br />

purpose.<br />

Spectacular and stress-free<br />

The <strong>Siempelkamp</strong> scope of supply does not only include the raw<br />

casting but also the mechanical machining of the casting and its<br />

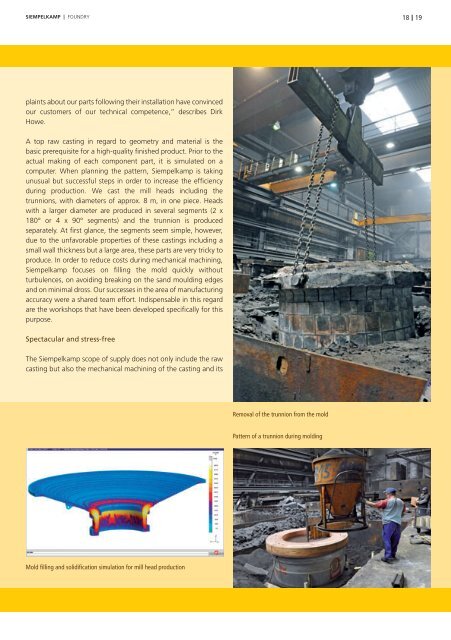

Mold fi lling and solidifi cation simulation for mill head production<br />

Removal of the trunnion from the mold<br />

Pattern of a trunnion during molding