Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SIEMPELKAMP | FOUNDRY/MACHINERY AND PLANTS 64 65<br />

For Alcoa, <strong>Siempelkamp</strong> is a well-known<br />

and trusted partner. <strong>Siempelkamp</strong> has<br />

developed and built several forging presses<br />

for Alcoa in the past. Both companies<br />

can look back on a relationship of mutual<br />

trust.<br />

Among other parts, the scope of supply<br />

for Alcoa consisted of 14 large cast parts<br />

for the upper, cross and lower beams as<br />

well as the foundation beams. For the<br />

manufacturing of these replacement<br />

parts, Alcoa had given three requirements:<br />

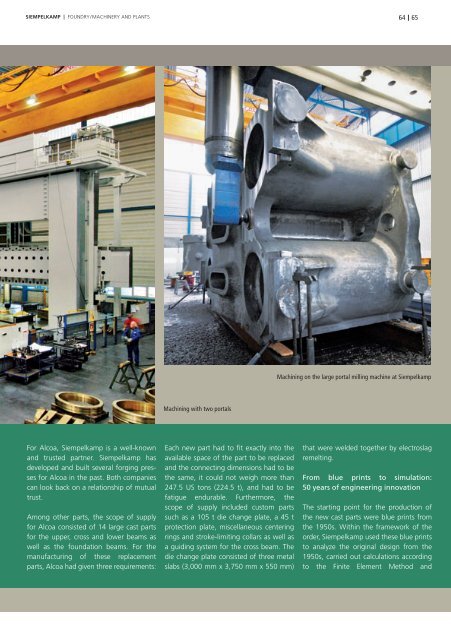

Machining with two portals<br />

Each new part had to fi t exactly into the<br />

available space of the part to be replaced<br />

and the connecting dimensions had to be<br />

the same, it could not weigh more than<br />

247.5 US tons (224.5 t), and had to be<br />

fatigue endurable. Furthermore, the<br />

scope of supply included custom parts<br />

such as a 105 t die change plate, a 45 t<br />

protection plate, miscellaneous centering<br />

rings and stroke-limiting collars as well as<br />

a guiding system for the cross beam. The<br />

die change plate consisted of three metal<br />

slabs (3,000 mm x 3,750 mm x 550 mm)<br />

Machining on the large portal milling machine at <strong>Siempelkamp</strong><br />

that were welded together by electroslag<br />

remelting.<br />

From blue prints to simulation:<br />

50 years of engineering innovation<br />

The starting point for the production of<br />

the new cast parts were blue prints from<br />

the 1950s. Within the framework of the<br />

order, <strong>Siempelkamp</strong> used these blue prints<br />

to analyze the original design from the<br />

1950s, carried out calculations according<br />

to the Finite Element Method and