Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

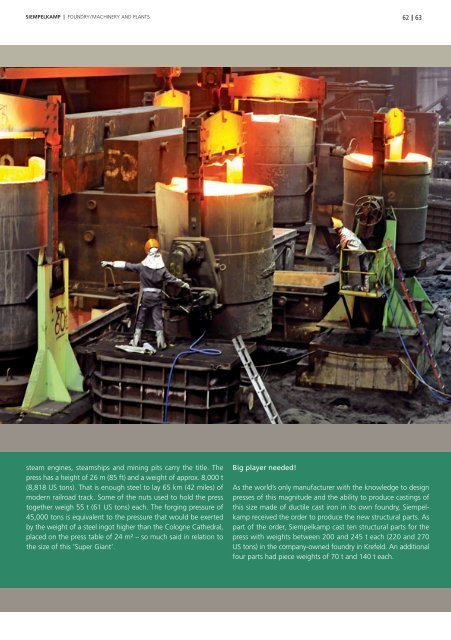

SIEMPELKAMP | FOUNDRY/MACHINERY AND PLANTS<br />

steam engines, steamships and mining pits carry the title. The<br />

press has a height of 26 m (85 ft) and a weight of approx. 8,000 t<br />

(8,818 US tons). That is enough steel to lay 65 km (42 miles) of<br />

modern railroad track. Some of the nuts used to hold the press<br />

together weigh 55 t (61 US tons) each. The forging pressure of<br />

45,000 tons is equivalent to the pressure that would be exerted<br />

by the weight of a steel ingot higher than the Cologne Cathedral,<br />

placed on the press table of 24 m² – so much said in relation to<br />

the size of this ‘Super Giant’.<br />

Big player needed!<br />

As the world’s only manufacturer with the knowledge to design<br />

presses of this magnitude and the ability to produce castings of<br />

this size made of ductile cast iron in its own foundry, <strong>Siempelkamp</strong><br />

received the order to produce the new structural parts. As<br />

part of the order, <strong>Siempelkamp</strong> cast ten structural parts for the<br />

press with weights between 200 and 245 t each (220 and 270<br />

US tons) in the company-owned foundry in Krefeld. An additional<br />

four parts had piece weights of 70 t and 140 t each.<br />

62<br />

63