Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SIEMPELKAMP | NUCLEAR TECHNOLOGY<br />

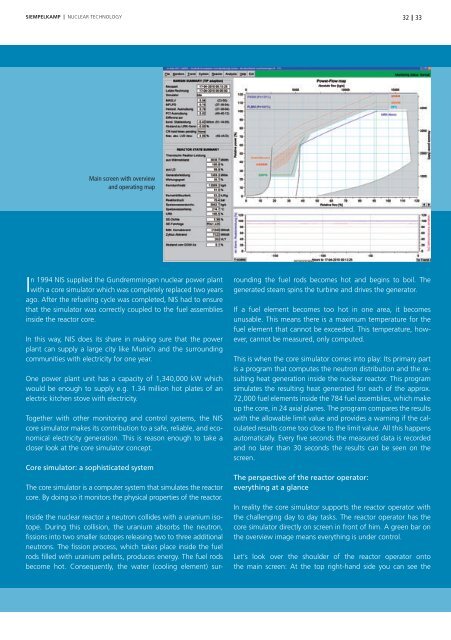

Main screen with overview<br />

and operating map<br />

In 1994 <strong>NIS</strong> supplied the Gundremmingen nuclear power plant<br />

with a core simulator which was completely replaced two years<br />

ago. After the refueling cycle was completed, <strong>NIS</strong> had to ensure<br />

that the simulator was correctly coupled to the fuel assemblies<br />

inside the reactor core.<br />

In this way, <strong>NIS</strong> does its share in making sure that the power<br />

plant can supply a large city like Munich and the surrounding<br />

communities with electricity for one year.<br />

One power plant unit has a capacity of 1,340,000 kW which<br />

would be enough to supply e.g. 1.34 million hot plates of an<br />

electric kitchen stove with electricity.<br />

Together with other monitoring and control systems, the <strong>NIS</strong><br />

core simulator makes its contribution to a safe, reliable, and economical<br />

electricity generation. This is reason enough to take a<br />

closer look at the core simulator concept.<br />

Core simulator: a sophisticated system<br />

The core simulator is a computer system that simulates the reactor<br />

core. By doing so it monitors the physical properties of the reactor.<br />

Inside the nuclear reactor a neutron collides with a uranium isotope.<br />

During this collision, the uranium absorbs the neutron,<br />

fi ssions into two smaller isotopes releasing two to three additional<br />

neutrons. The fi ssion process, which takes place inside the fuel<br />

rods fi lled with uranium pellets, produces energy. The fuel rods<br />

become hot. Consequently, the water (cooling element) sur-<br />

rounding the fuel rods becomes hot and begins to boil. The<br />

generated steam spins the turbine and drives the generator.<br />

If a fuel element becomes too hot in one area, it becomes<br />

unusable. This means there is a maximum temperature for the<br />

fuel element that cannot be exceeded. This temperature, however,<br />

cannot be measured, only computed.<br />

This is when the core simulator comes into play: Its primary part<br />

is a program that computes the neutron distribution and the resulting<br />

heat generation inside the nuclear reactor. This program<br />

simulates the resulting heat generated for each of the approx.<br />

72,000 fuel elements inside the 784 fuel assemblies, which make<br />

up the core, in 24 axial planes. The program compares the results<br />

with the allowable limit value and provides a warning if the calculated<br />

results come too close to the limit value. All this happens<br />

automatically. Every fi ve seconds the measured data is recorded<br />

and no later than 30 seconds the results can be seen on the<br />

screen.<br />

The perspective of the reactor operator:<br />

everything at a glance<br />

In reality the core simulator supports the reactor operator with<br />

the challenging day to day tasks. The reactor operator has the<br />

core simulator directly on screen in front of him. A green bar on<br />

the overview image means everything is under control.<br />

Let‘s look over the shoulder of the reactor operator onto<br />

the main screen: At the top right-hand side you can see the<br />

32<br />

33