Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

Bulletin 2/2010 - Siempelkamp NIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

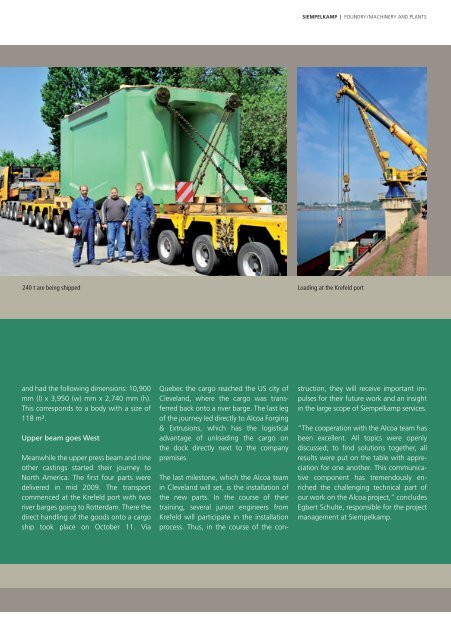

240 t are being shipped<br />

and had the following dimensions: 10,900<br />

mm (l) x 3,950 (w) mm x 2,740 mm (h).<br />

This corresponds to a body with a size of<br />

118 m³.<br />

Upper beam goes West<br />

Meanwhile the upper press beam and nine<br />

other castings started their journey to<br />

North America. The fi rst four parts were<br />

delivered in mid 2009. The transport<br />

commenced at the Krefeld port with two<br />

river barges going to Rotterdam. There the<br />

direct handling of the goods onto a cargo<br />

ship took place on October 11. Via<br />

Quebec the cargo reached the US city of<br />

Cleveland, where the cargo was transferred<br />

back onto a river barge. The last leg<br />

of the journey led directly to Alcoa Forging<br />

& Extrusions, which has the logistical<br />

advantage of unloading the cargo on<br />

the dock directly next to the company<br />

premises.<br />

The last milestone, which the Alcoa team<br />

in Cleveland will set, is the installation of<br />

the new parts. In the course of their<br />

training, several junior engineers from<br />

Krefeld will participate in the installation<br />

process. Thus, in the course of the con-<br />

SIEMPELKAMP | FOUNDRY/MACHINERY AND PLANTS<br />

Loading at the Krefeld port<br />

struction, they will receive important impulses<br />

for their future work and an insight<br />

in the large scope of <strong>Siempelkamp</strong> services.<br />

“The cooperation with the Alcoa team has<br />

been excellent. All topics were openly<br />

discussed; to fi nd solutions together, all<br />

results were put on the table with appreciation<br />

for one another. This communicative<br />

component has tremendously enriched<br />

the challenging technical part of<br />

our work on the Alcoa project,” concludes<br />

Egbert Schulte, responsible for the project<br />

management at <strong>Siempelkamp</strong>.