Abstract SYMPHOS 2011

Abstract SYMPHOS 2011

Abstract SYMPHOS 2011

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

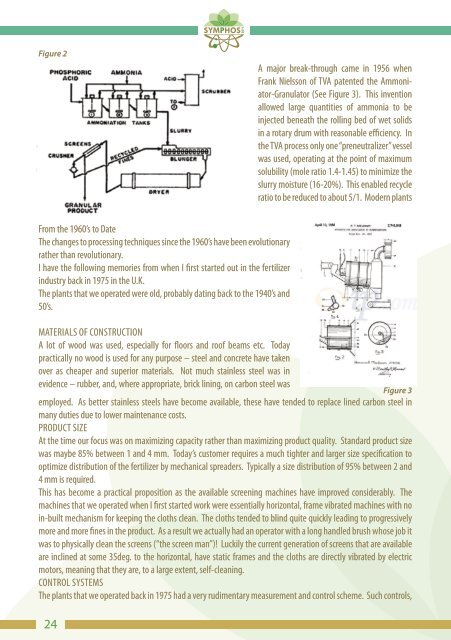

Figure 2<br />

From the 1960’s to Date<br />

The changes to processing techniques since the 1960’s have been evolutionary<br />

rather than revolutionary.<br />

I have the following memories from when I first started out in the fertilizer<br />

industry back in 1975 in the U.K.<br />

The plants that we operated were old, probably dating back to the 1940’s and<br />

50’s.<br />

MATERIALS OF CONSTRUCTION<br />

A lot of wood was used, especially for floors and roof beams etc. Today<br />

practically no wood is used for any purpose – steel and concrete have taken<br />

over as cheaper and superior materials. Not much stainless steel was in<br />

evidence – rubber, and, where appropriate, brick lining, on carbon steel was<br />

employed. As better stainless steels have become available, these have tended to replace lined carbon steel in<br />

many duties due to lower maintenance costs.<br />

PRODUCT SIZE<br />

At the time our focus was on maximizing capacity rather than maximizing product quality. Standard product size<br />

was maybe 85% between 1 and 4 mm. Today’s customer requires a much tighter and larger size specification to<br />

optimize distribution of the fertilizer by mechanical spreaders. Typically a size distribution of 95% between 2 and<br />

4 mm is required.<br />

This has become a practical proposition as the available screening machines have improved considerably. The<br />

machines that we operated when I first started work were essentially horizontal, frame vibrated machines with no<br />

in-built mechanism for keeping the cloths clean. The cloths tended to blind quite quickly leading to progressively<br />

more and more fines in the product. As a result we actually had an operator with a long handled brush whose job it<br />

was to physically clean the screens (“the screen man”)! Luckily the current generation of screens that are available<br />

are inclined at some 35deg. to the horizontal, have static frames and the cloths are directly vibrated by electric<br />

motors, meaning that they are, to a large extent, self-cleaning.<br />

CONTROL SYSTEMS<br />

The plants that we operated back in 1975 had a very rudimentary measurement and control scheme. Such controls,<br />

24<br />

A major break-through came in 1956 when<br />

Frank Nielsson of TVA patented the Ammoniator-Granulator<br />

(See Figure 3). This invention<br />

allowed large quantities of ammonia to be<br />

injected beneath the rolling bed of wet solids<br />

in a rotary drum with reasonable efficiency. In<br />

the TVA process only one “preneutralizer” vessel<br />

was used, operating at the point of maximum<br />

solubility (mole ratio 1.4-1.45) to minimize the<br />

slurry moisture (16-20%). This enabled recycle<br />

ratio to be reduced to about 5/1. Modern plants<br />

Figure 3