Abstract SYMPHOS 2011

Abstract SYMPHOS 2011

Abstract SYMPHOS 2011

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

By Eng. Luis María de Urquiola<br />

Technical Manager<br />

COMSPAIN<br />

COOLING FERTILIZERS AND PHOSPHATES :<br />

BY ROTARY DRUM OR FLUID BED ?<br />

PH-O-10<br />

OVER 30 years ago, fluidification – the use of the fluid bed – began to be adopted on a commercial scale by industry.<br />

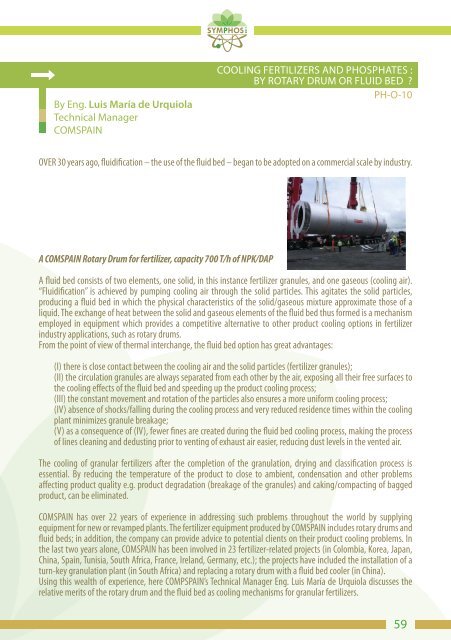

A COMSPAIN Rotary Drum for fertilizer, capacity 700 T/h of NPK/DAP<br />

A fluid bed consists of two elements, one solid, in this instance fertilizer granules, and one gaseous (cooling air).<br />

“Fluidification” is achieved by pumping cooling air through the solid particles. This agitates the solid particles,<br />

producing a fluid bed in which the physical characteristics of the solid/gaseous mixture approximate those of a<br />

liquid. The exchange of heat between the solid and gaseous elements of the fluid bed thus formed is a mechanism<br />

employed in equipment which provides a competitive alternative to other product cooling options in fertilizer<br />

industry applications, such as rotary drums.<br />

From the point of view of thermal interchange, the fluid bed option has great advantages:<br />

(I) there is close contact between the cooling air and the solid particles (fertilizer granules);<br />

(II) the circulation granules are always separated from each other by the air, exposing all their free surfaces to<br />

the cooling effects of the fluid bed and speeding up the product cooling process;<br />

(III) the constant movement and rotation of the particles also ensures a more uniform cooling process;<br />

(IV) absence of shocks/falling during the cooling process and very reduced residence times within the cooling<br />

plant minimizes granule breakage;<br />

(V) as a consequence of (IV), fewer fines are created during the fluid bed cooling process, making the process<br />

of lines cleaning and dedusting prior to venting of exhaust air easier, reducing dust levels in the vented air.<br />

The cooling of granular fertilizers after the completion of the granulation, drying and classification process is<br />

essential. By reducing the temperature of the product to close to ambient, condensation and other problems<br />

affecting product quality e.g. product degradation (breakage of the granules) and caking/compacting of bagged<br />

product, can be eliminated.<br />

COMSPAIN has over 22 years of experience in addressing such problems throughout the world by supplying<br />

equipment for new or revamped plants. The fertilizer equipment produced by COMSPAIN includes rotary drums and<br />

fluid beds; in addition, the company can provide advice to potential clients on their product cooling problems. In<br />

the last two years alone, COMSPAIN has been involved in 23 fertilizer-related projects (in Colombia, Korea, Japan,<br />

China, Spain, Tunisia, South Africa, France, Ireland, Germany, etc.); the projects have included the installation of a<br />

turn-key granulation plant (in South Africa) and replacing a rotary drum with a fluid bed cooler (in China).<br />

Using this wealth of experience, here COMPSPAIN’s Technical Manager Eng. Luis María de Urquiola discusses the<br />

relative merits of the rotary drum and the fluid bed as cooling mechanisms for granular fertilizers.<br />

59