Download (5Mb) - Covenant University Repository

Download (5Mb) - Covenant University Repository

Download (5Mb) - Covenant University Repository

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

act as weak points when the fabric is elongated under<br />

stress. In addition, the amount of static charge decreased<br />

as a result of lipase treatment of PET. This may be<br />

attributed to the creation of hydroxyl and carboxyl groups<br />

consequently enhanced the moisture regain and the<br />

amount of static charge decreased. Improvement of pilling<br />

resistance and dissipation of electrostatic charge soil<br />

release resistance were noticed. Lipase pretreatment of<br />

PET also reduced the susceptibility of the fabric to stain<br />

by corn oil in comparison to the control. Presumably<br />

enzymatic hydrolysis of PET and formation of hydroxyl<br />

and carboxyl groups decrease hydrophobicity and<br />

attraction for oily soil thereby enabling the easier removal<br />

of the corn oil stain.<br />

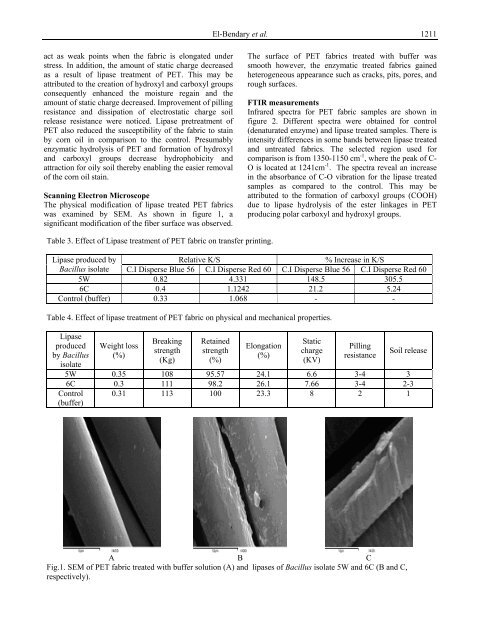

Scanning Electron Microscope<br />

The physical modification of lipase treated PET fabrics<br />

was examined by SEM. As shown in figure 1, a<br />

significant modification of the fiber surface was observed.<br />

El-Bendary et al.<br />

Table 3. Effect of Lipase treatment of PET fabric on transfer printing.<br />

1211<br />

The surface of PET fabrics treated with buffer was<br />

smooth however, the enzymatic treated fabrics gained<br />

heterogeneous appearance such as cracks, pits, pores, and<br />

rough surfaces.<br />

FTIR measurements<br />

Infrared spectra for PET fabric samples are shown in<br />

figure 2. Different spectra were obtained for control<br />

(denaturated enzyme) and lipase treated samples. There is<br />

intensity differences in some bands between lipase treated<br />

and untreated fabrics. The selected region used for<br />

comparison is from 1350-1150 cm -1 , where the peak of C-<br />

O is located at 1241cm -1 . The spectra reveal an increase<br />

in the absorbance of C-O vibration for the lipase treated<br />

samples as compared to the control. This may be<br />

attributed to the formation of carboxyl groups (COOH)<br />

due to lipase hydrolysis of the ester linkages in PET<br />

producing polar carboxyl and hydroxyl groups.<br />

Lipase produced by<br />

Relative K/S % Increase in K/S<br />

Bacillus isolate C.I Disperse Blue 56 C.I Disperse Red 60 C.I Disperse Blue 56 C.I Disperse Red 60<br />

5W 0.82 4.331 148.5 305.5<br />

6C 0.4 1.1242 21.2 5.24<br />

Control (buffer) 0.33 1.068 - -<br />

Table 4. Effect of lipase treatment of PET fabric on physical and mechanical properties.<br />

Lipase<br />

produced<br />

by Bacillus<br />

isolate<br />

Weight loss<br />

(%)<br />

Breaking<br />

strength<br />

(Kg)<br />

Retained<br />

strength<br />

(%)<br />

Elongation<br />

(%)<br />

Static<br />

charge<br />

(KV)<br />

Pilling<br />

resistance<br />

Soil release<br />

5W 0.35 108 95.57 24.1 6.6 3-4 3<br />

6C 0.3 111 98.2 26.1 7.66 3-4 2-3<br />

Control<br />

(buffer)<br />

0.31 113 100 23.3 8 2 1<br />

A<br />

B<br />

C<br />

Fig.1. SEM of PET fabric treated with buffer solution (A) and lipases of Bacillus isolate 5W and 6C (B and C,<br />

respectively).