Troels Dyhr Pedersen.indd - Solid Mechanics

Troels Dyhr Pedersen.indd - Solid Mechanics

Troels Dyhr Pedersen.indd - Solid Mechanics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Emissions<br />

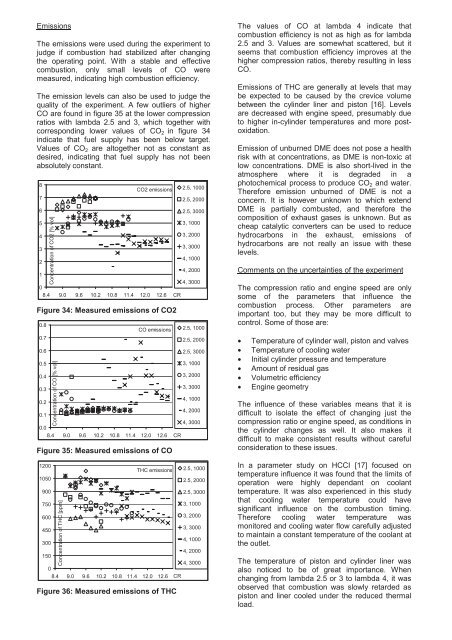

The emissions were used during the experiment to<br />

judge if combustion had stabilized after changing<br />

the operating point. With a stable and effective<br />

combustion, only small levels of CO were<br />

measured, indicating high combustion efficiency.<br />

The emission levels can also be used to judge the<br />

quality of the experiment. A few outliers of higher<br />

CO are found in figure 35 at the lower compression<br />

ratios with lambda 2.5 and 3, which together with<br />

corresponding lower values of CO2 in figure 34<br />

indicate that fuel supply has been below target.<br />

Values of CO2 are altogether not as constant as<br />

desired, indicating that fuel supply has not been<br />

absolutely constant.<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Concentration of CO2 [% vol]<br />

CO2 emissions<br />

2.5, 1000<br />

2.5, 2000<br />

2.5, 3000<br />

3, 1000<br />

3, 2000<br />

3, 3000<br />

4, 1000<br />

4, 2000<br />

1<br />

4, 3000<br />

0<br />

8.4 9.0 9.6 10.2 10.8 11.4 12.0 12.6 CR<br />

Figure 34: Measured emissions of CO2<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

Concentration of CO [% vol]<br />

CO emissions<br />

2.5, 1000<br />

2.5, 2000<br />

2.5, 3000<br />

3, 1000<br />

3, 2000<br />

3, 3000<br />

4, 1000<br />

4, 2000<br />

0.1<br />

4, 3000<br />

0.0<br />

8.4 9.0 9.6 10.2 10.8 11.4 12.0 12.6 CR<br />

Figure 35: Measured emissions of CO<br />

1200<br />

1050<br />

900<br />

750<br />

600<br />

450<br />

300<br />

Concentration of THC [ppm]<br />

THC emissions<br />

2.5, 1000<br />

2.5, 2000<br />

2.5, 3000<br />

3, 1000<br />

3, 2000<br />

3, 3000<br />

4, 1000<br />

4, 2000<br />

150<br />

4, 3000<br />

0<br />

8.4 9.0 9.6 10.2 10.8 11.4 12.0 12.6 CR<br />

Figure 36: Measured emissions of THC<br />

The values of CO at lambda 4 indicate that<br />

combustion efficiency is not as high as for lambda<br />

2.5 and 3. Values are somewhat scattered, but it<br />

seems that combustion efficiency improves at the<br />

higher compression ratios, thereby resulting in less<br />

CO.<br />

Emissions of THC are generally at levels that may<br />

be expected to be caused by the crevice volume<br />

between the cylinder liner and piston [16]. Levels<br />

are decreased with engine speed, presumably due<br />

to higher in-cylinder temperatures and more postoxidation.<br />

Emission of unburned DME does not pose a health<br />

risk with at concentrations, as DME is non-toxic at<br />

low concentrations. DME is also short-lived in the<br />

atmosphere where it is degraded in a<br />

photochemical process to produce CO2 and water.<br />

Therefore emission unburned of DME is not a<br />

concern. It is however unknown to which extend<br />

DME is partially combusted, and therefore the<br />

composition of exhaust gases is unknown. But as<br />

cheap catalytic converters can be used to reduce<br />

hydrocarbons in the exhaust, emissions of<br />

hydrocarbons are not really an issue with these<br />

levels.<br />

Comments on the uncertainties of the experiment<br />

The compression ratio and engine speed are only<br />

some of the parameters that influence the<br />

combustion process. Other parameters are<br />

important too, but they may be more difficult to<br />

control. Some of those are:<br />

• Temperature of cylinder wall, piston and valves<br />

• Temperature of cooling water<br />

• Initial cylinder pressure and temperature<br />

• Amount of residual gas<br />

• Volumetric efficiency<br />

• Engine geometry<br />

The influence of these variables means that it is<br />

difficult to isolate the effect of changing just the<br />

compression ratio or engine speed, as conditions in<br />

the cylinder changes as well. It also makes it<br />

difficult to make consistent results without careful<br />

consideration to these issues.<br />

In a parameter study on HCCI [17] focused on<br />

temperature influence it was found that the limits of<br />

operation were highly dependant on coolant<br />

temperature. It was also experienced in this study<br />

that cooling water temperature could have<br />

significant influence on the combustion timing.<br />

Therefore cooling water temperature was<br />

monitored and cooling water flow carefully adjusted<br />

to maintain a constant temperature of the coolant at<br />

the outlet.<br />

The temperature of piston and cylinder liner was<br />

also noticed to be of great importance. When<br />

changing from lambda 2.5 or 3 to lambda 4, it was<br />

observed that combustion was slowly retarded as<br />

piston and liner cooled under the reduced thermal<br />

load.