Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:270<br />

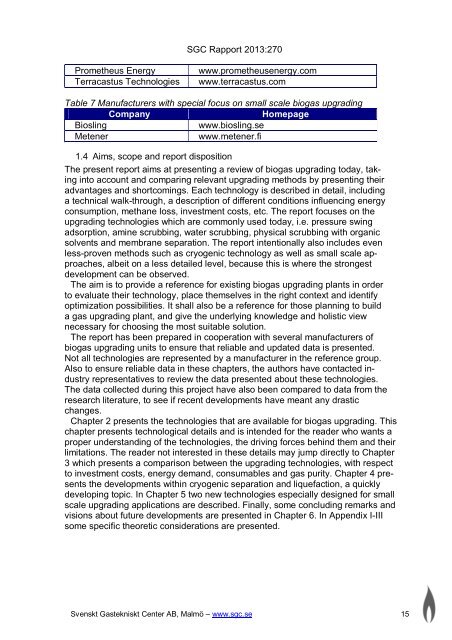

Prometheus Energy www.prometheusenergy.com<br />

Terracastus Technologies www.terracastus.com<br />

Table 7 Manufacturers with special focus on small scale biogas <strong>upgrading</strong><br />

Company Homepage<br />

Biosling www.biosling.se<br />

Metener www.metener.fi<br />

1.4 Aims, scope and report disposition<br />

The present report aims at presenting a review <strong>of</strong> biogas <strong>upgrading</strong> today, taking<br />

into account and comparing relevant <strong>upgrading</strong> methods by presenting their<br />

advantages and shortcomings. Each technology is described in detail, including<br />

a technical walk-through, a description <strong>of</strong> different conditions influencing energy<br />

consumption, methane loss, investment costs, etc. The report focuses on the<br />

<strong>upgrading</strong> <strong>technologies</strong> which are commonly used today, i.e. pressure swing<br />

adsorption, amine scrubbing, water scrubbing, physical scrubbing with organic<br />

solvents and membrane separation. The report intentionally also includes even<br />

less-proven methods such as cryogenic technology as well as small scale approaches,<br />

albeit on a less detailed level, because this is where the strongest<br />

development can be observed.<br />

The aim is to provide a reference for existing biogas <strong>upgrading</strong> plants in order<br />

to evaluate their technology, place themselves in the right context and identify<br />

optimization possibilities. It shall also be a reference for those planning to build<br />

a gas <strong>upgrading</strong> plant, and give the underlying knowledge and holistic view<br />

necessary for choosing the most suitable solution.<br />

The report has been prepared in cooperation with several manufacturers <strong>of</strong><br />

biogas <strong>upgrading</strong> units to ensure that reliable and updated data is presented.<br />

Not all <strong>technologies</strong> are represented by a manufacturer in the reference group.<br />

Also to ensure reliable data in these chapters, the authors have contacted industry<br />

representatives to review the data presented about these <strong>technologies</strong>.<br />

The data collected during this project have also been compared to data from the<br />

research literature, to see if recent developments have meant any drastic<br />

changes.<br />

Chapter 2 presents the <strong>technologies</strong> that are available for biogas <strong>upgrading</strong>. This<br />

chapter presents technological details and is intended for the reader who wants a<br />

proper understanding <strong>of</strong> the <strong>technologies</strong>, the driving forces behind them and their<br />

limitations. The reader not interested in these details may jump directly to Chapter<br />

3 which presents a comparison between the <strong>upgrading</strong> <strong>technologies</strong>, with respect<br />

to investment costs, energy demand, consumables and gas purity. Chapter 4 presents<br />

the developments within cryogenic separation and liquefaction, a quickly<br />

developing topic. In Chapter 5 two new <strong>technologies</strong> especially designed for small<br />

scale <strong>upgrading</strong> applications are described. Finally, some concluding remarks and<br />

visions about future developments are presented in Chapter 6. In Appendix I-III<br />

some specific theoretic considerations are presented.<br />

Svenskt Gastekniskt Center AB, Malmö <strong>–</strong> www.sgc.se 15