Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:270<br />

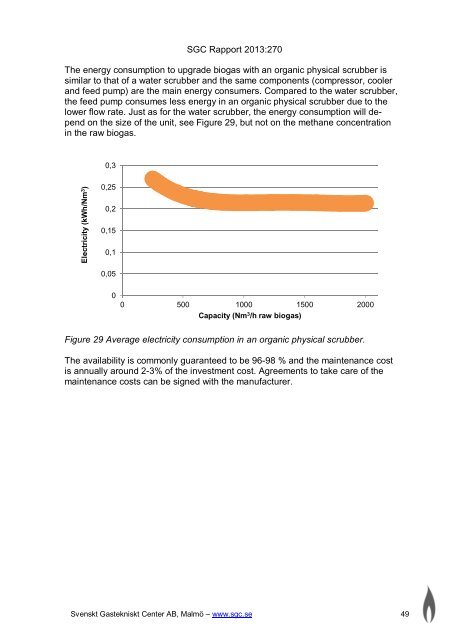

The energy consumption to upgrade biogas with an organic physical scrubber is<br />

similar to that <strong>of</strong> a water scrubber and the same components (compressor, cooler<br />

and feed pump) are the main energy consumers. Compared to the water scrubber,<br />

the feed pump consumes less energy in an organic physical scrubber due to the<br />

lower flow rate. Just as for the water scrubber, the energy consumption will depend<br />

on the size <strong>of</strong> the unit, see Figure 29, but not on the methane concentration<br />

in the raw biogas.<br />

Electricity (kWh/Nm 3 )<br />

0,3<br />

0,25<br />

0,2<br />

0,15<br />

0,1<br />

0,05<br />

0<br />

0 500 1000 1500 2000<br />

Capacity (Nm3 /h raw biogas)<br />

Figure 29 Average electricity consumption in an organic physical scrubber.<br />

The availability is commonly guaranteed to be 96-98 % and the maintenance cost<br />

is annually around 2-3% <strong>of</strong> the investment cost. Agreements to take care <strong>of</strong> the<br />

maintenance costs can be signed with the manufacturer.<br />

Svenskt Gastekniskt Center AB, Malmö <strong>–</strong> www.sgc.se 49