Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:270<br />

solubility <strong>of</strong> methane according to Eq. 4. The water that is transported to the desorption<br />

column will contain the main part <strong>of</strong> the carbon dioxide but less than 1%<br />

<strong>of</strong> the methane in the raw biogas.<br />

The pressure in the flash column has to be decreased to maintain the same methane<br />

slip if the methane concentration in the raw biogas increases. The reason is<br />

that more methane and less carbon dioxide is transported with the water into the<br />

flash column, resulting in a changed composition <strong>–</strong> more CH4 and less CO2 <strong>–</strong> in<br />

the flash column gas volume. If the pressure is kept constant, the partial pressure<br />

<strong>of</strong> methane will increase significantly resulting in higher solubility in the water according<br />

to Eq. 4. For a system working at 8 bar(a), the flash pressure has to be<br />

decreased from about 3 bar(a) to about 2 bar(a) when the methane concentration<br />

is increased from 50% to 80% in the incoming raw biogas.<br />

The flash column has no packing and is designed with a diameter wide enough<br />

to decrease the vertical speed <strong>of</strong> the water to such an extent that even small gas<br />

bubbles are able to rise instead <strong>of</strong> being dragged into the desorption column. The<br />

top <strong>of</strong> the flash column should be designed so that water is not sucked into the gas<br />

going back to the compressor. The volume <strong>of</strong> this gas stream going back to the<br />

compressor is usually 20-30% <strong>of</strong> the incoming raw gas flow.<br />

After removing most <strong>of</strong> the methane from the water in the flash column, the carbon<br />

dioxide is released from the water in the desorption column. The water enters<br />

the top <strong>of</strong> the desorption column, while air is entering at the bottom. This column is<br />

also filled with random packing to increase the contact surface between the air and<br />

the water. The low percentage <strong>of</strong> carbon dioxide in the air in combination with decreased<br />

pressure results in a partial pressure <strong>of</strong> carbon dioxide close to zero and<br />

thus a very low solubility <strong>of</strong> carbon dioxide in the water. The water leaving the desorption<br />

column is virtually free from carbon dioxide and is pumped back into the<br />

top <strong>of</strong> the absorption column. The time it takes to circulate a specific volume <strong>of</strong><br />

water one time in a water scrubbing system is around 1-5 minutes depending on<br />

design and current load.<br />

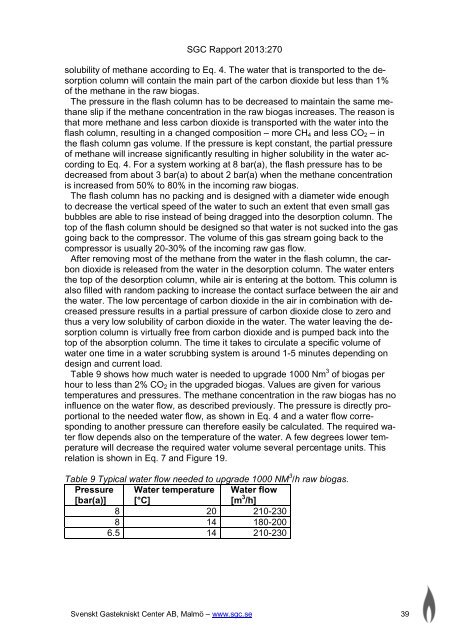

Table 9 shows how much water is needed to upgrade 1000 Nm 3 <strong>of</strong> biogas per<br />

hour to less than 2% CO2 in the upgraded biogas. Values are given for various<br />

temperatures and pressures. The methane concentration in the raw biogas has no<br />

influence on the water flow, as described previously. The pressure is directly proportional<br />

to the needed water flow, as shown in Eq. 4 and a water flow corresponding<br />

to another pressure can therefore easily be calculated. The required water<br />

flow depends also on the temperature <strong>of</strong> the water. A few degrees lower temperature<br />

will decrease the required water volume several percentage units. This<br />

relation is shown in Eq. 7 and Figure 19.<br />

Table 9 Typical water flow needed to upgrade 1000 NM 3 /h raw biogas.<br />

Pressure Water temperature Water flow<br />

[bar(a)] [°C]<br />

[m 3 /h]<br />

8 20 210-230<br />

8 14 180-200<br />

6.5 14 210-230<br />

Svenskt Gastekniskt Center AB, Malmö <strong>–</strong> www.sgc.se 39