Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:270<br />

Using a filter with activated carbon to separate H2S before the PSA columns will<br />

include a consumption <strong>of</strong> activated carbon for this separation. This demand is<br />

however rather limited. Maintenance <strong>of</strong> a PSA-unit is usually planned to twice a<br />

year, according to system producers.<br />

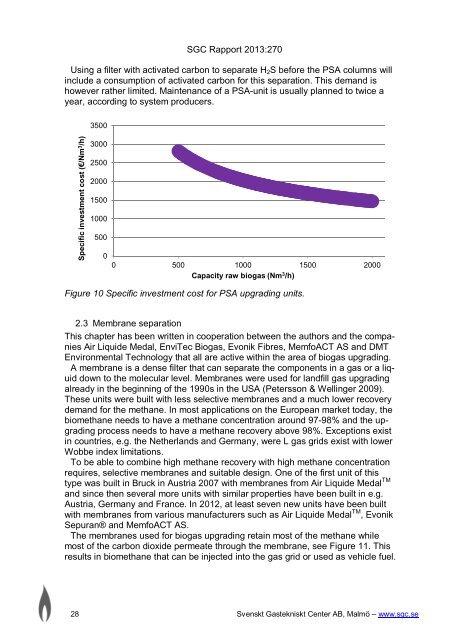

Specific investment cost (€/Nm 3 /h)<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

0 500 1000<br />

Capacity raw biogas (Nm<br />

1500 2000<br />

3 /h)<br />

Figure 10 Specific investment cost for PSA <strong>upgrading</strong> units.<br />

2.3 Membrane separation<br />

This chapter has been written in cooperation between the authors and the companies<br />

Air Liquide Medal, EnviTec <strong>Biogas</strong>, Evonik Fibres, MemfoACT AS and DMT<br />

Environmental Technology that all are active within the area <strong>of</strong> biogas <strong>upgrading</strong>.<br />

A membrane is a dense filter that can separate the components in a gas or a liquid<br />

down to the molecular level. Membranes were used for landfill gas <strong>upgrading</strong><br />

already in the beginning <strong>of</strong> the 1990s in the USA (Petersson & Wellinger 2009).<br />

These units were built with less selective membranes and a much lower recovery<br />

demand for the methane. In most applications on the European market today, the<br />

biomethane needs to have a methane concentration around 97-98% and the <strong>upgrading</strong><br />

process needs to have a methane recovery above 98%. Exceptions exist<br />

in countries, e.g. the Netherlands and Germany, were L gas grids exist with lower<br />

Wobbe index limitations.<br />

To be able to combine high methane recovery with high methane concentration<br />

requires, selective membranes and suitable design. One <strong>of</strong> the first unit <strong>of</strong> this<br />

type was built in Bruck in Austria 2007 with membranes from Air Liquide Medal TM<br />

and since then several more units with similar properties have been built in e.g.<br />

Austria, Germany and France. In 2012, at least seven new units have been built<br />

with membranes from various manufacturers such as Air Liquide Medal TM , Evonik<br />

Sepuran® and MemfoACT AS.<br />

The membranes used for biogas <strong>upgrading</strong> retain most <strong>of</strong> the methane while<br />

most <strong>of</strong> the carbon dioxide permeate through the membrane, see Figure 11. This<br />

results in biomethane that can be injected into the gas grid or used as vehicle fuel.<br />

28 Svenskt Gastekniskt Center AB, Malmö <strong>–</strong> www.sgc.se