Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Biogas upgrading – Review of commercial technologies - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:270<br />

2.2 Pressure swing adsorption<br />

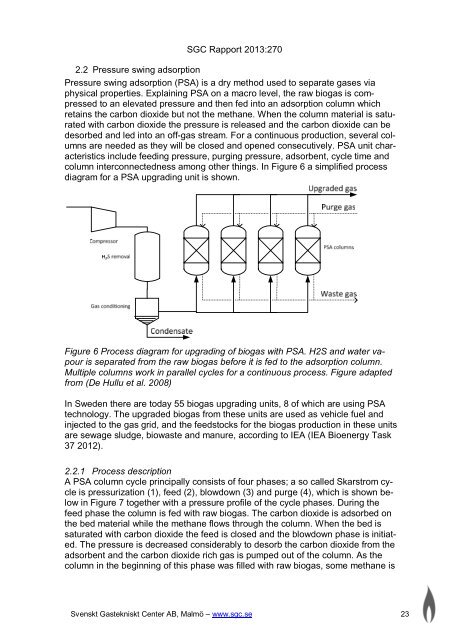

Pressure swing adsorption (PSA) is a dry method used to separate gases via<br />

physical properties. Explaining PSA on a macro level, the raw biogas is compressed<br />

to an elevated pressure and then fed into an adsorption column which<br />

retains the carbon dioxide but not the methane. When the column material is saturated<br />

with carbon dioxide the pressure is released and the carbon dioxide can be<br />

desorbed and led into an <strong>of</strong>f-gas stream. For a continuous production, several columns<br />

are needed as they will be closed and opened consecutively. PSA unit characteristics<br />

include feeding pressure, purging pressure, adsorbent, cycle time and<br />

column interconnectedness among other things. In Figure 6 a simplified process<br />

diagram for a PSA <strong>upgrading</strong> unit is shown.<br />

Figure 6 Process diagram for <strong>upgrading</strong> <strong>of</strong> biogas with PSA. H2S and water vapour<br />

is separated from the raw biogas before it is fed to the adsorption column.<br />

Multiple columns work in parallel cycles for a continuous process. Figure adapted<br />

from (De Hullu et al. 2008)<br />

In Sweden there are today 55 biogas <strong>upgrading</strong> units, 8 <strong>of</strong> which are using PSA<br />

technology. The upgraded biogas from these units are used as vehicle fuel and<br />

injected to the gas grid, and the feedstocks for the biogas production in these units<br />

are sewage sludge, biowaste and manure, according to IEA (IEA Bioenergy Task<br />

37 2012).<br />

2.2.1 Process description<br />

A PSA column cycle principally consists <strong>of</strong> four phases; a so called Skarstrom cycle<br />

is pressurization (1), feed (2), blowdown (3) and purge (4), which is shown below<br />

in Figure 7 together with a pressure pr<strong>of</strong>ile <strong>of</strong> the cycle phases. During the<br />

feed phase the column is fed with raw biogas. The carbon dioxide is adsorbed on<br />

the bed material while the methane flows through the column. When the bed is<br />

saturated with carbon dioxide the feed is closed and the blowdown phase is initiated.<br />

The pressure is decreased considerably to desorb the carbon dioxide from the<br />

adsorbent and the carbon dioxide rich gas is pumped out <strong>of</strong> the column. As the<br />

column in the beginning <strong>of</strong> this phase was filled with raw biogas, some methane is<br />

Svenskt Gastekniskt Center AB, Malmö <strong>–</strong> www.sgc.se 23