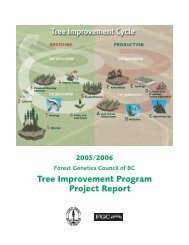

Tree Improvement Program Project Report 2006 / 2007

Tree Improvement Program Project Report 2006 / 2007

Tree Improvement Program Project Report 2006 / 2007

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ut there was a substantial decrease in potential seedlings.<br />

We found no fungal contamination (Fusarium spp.) or<br />

infection (Caloscypha fulgens) in any of the seed fractions.<br />

The liquid separation was not very efficient because the<br />

poor fraction still germinated at 43 percent, although with<br />

the attempt to remove the chitted seed, we expected that<br />

some germination would occur in the poor fraction. We<br />

don’t consider this effort a success, and future upgrading<br />

efforts with seed lots of similar seed characteristics and<br />

quality are likely to produce similar results.<br />

Portion Volume Pot. <strong>Tree</strong>s D1 GC W1 GC G20 GC<br />

CONTROL 96.0 Kg 6.36 M 67% 50% 39%<br />

Upgraded 80.3 Kg 5.48 M 70% 42% 40%<br />

Poor 15.5 Kg 0.62 M 43% 29% 18%<br />

Table 2 .<br />

.3. Eng neer ng Consultat on<br />

for K ln and/or Controller<br />

Upgrades: <strong>Project</strong> 0 7E27<br />

Dave Kolotelo<br />

The funds for to this project were allocated to two separate<br />

kiln projects:<br />

a) training and upgrades to our ARGUS Control System<br />

b) engineering evaluation of our kiln<br />

With regard to our ARGUS system, we had a meeting<br />

with one of the manufacturer’s technicians/programmers<br />

to better understand the operational complexities of our<br />

kiln programming. We also invested in an upgrade to our<br />

ARGUS software, including some application engineering<br />

time.<br />

To obtain an engineering evaluation of our kiln,<br />

we extended an invitation to quote, and the successful<br />

company was Custom Air Conditioning Ltd. The primary<br />

issues addressed were the inability to maintain humidity<br />

levels and the inability to keep temperatures within the kiln<br />

at the desired set points. A thorough investigation of the<br />

mechanical system determined that:<br />

a) all components were operating properly<br />

T R E E I M P R O V E M E N T P R O G R A M<br />

P R O J E C T R E P O R T 2 0 0 6 / 2 0 0 7<br />

b) the temperature variation was within acceptable<br />

parameters (± 2°F)<br />

c) the burner completely shuts down after reaching set point<br />

d) high temperature overshoot is attempted to be overcome<br />

by venting<br />

e) humidity set points are not achievable over the duration<br />

of the kiln<br />

f) the burner system is antiquated and not energy efficient<br />

by today’s standards<br />

The engineering recommendation is that even with<br />

significant modifications to our existing kiln, we will not<br />

be able to maintain both temperature and humidity set<br />

points. At 21 years of age and without any modifications,<br />

our existing kiln design is perhaps beyond its period of useful<br />

life. The recommendation is to remove the existing burner<br />

configuration and replace it with a packaged dehumidifier<br />

system (heat pump) with the ability to add steam to the kiln.<br />

This is a very energy efficient system and will reduce natural<br />

gas use.<br />

The total cost of this improvement is in the range<br />

of $75,000 to $100,000, and equipment delivery and<br />

installation would require approximately 17-22 weeks. No<br />

other minor changes were recommended, and that is why the<br />

project spent only about 60 percent of the allotted funding.<br />

6.0 Extens on and<br />

Commun cat ons<br />

6.1 ETAC Extens on and<br />

Commun cat ons<br />

D ane Douglas<br />

F eld Tours and Workshops<br />

• Prince George area field tour – Anna Monetta with the<br />

Northern Silviculture Committee (NSC) approached<br />

ETAC regarding a Forest Genetics field tour following<br />

the June NSC on June 22, <strong>2006</strong>. The tour was a<br />

resounding success, with registration logistics handled<br />

by Rob Bryce of UNBC and excellent presentations by<br />

Michael Carlson, Barry Jaquish, and Richard Reich.<br />

David Reid and Rita Wagner hosted the tour of PGTIS.<br />

73