You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

April, 1905 COAL AND TIMBER 13<br />

this holds good whether one locomotive<br />

is in use or 20, and that all of the locomotives<br />

Supplied by the compressor can be<br />

worked at their full power simultaneously,<br />

or all can be idle, without affecting the uniform<br />

economical operation of the compressor.<br />

This, they assert, means the economical<br />

use of steam and the saving of fuel<br />

used to produce it. This fact, it is asserted,<br />

is never made use of by theorists<br />

when writing articles on electric hauling.<br />

One objection is frequently made against<br />

the use of compressed air on the ground<br />

that much power is lost through the great<br />

friction developed by the compressed air<br />

passing through a long pipe, especially<br />

where small pipe is used. This objection,<br />

is declared to be wholly theoretical. Mind not<br />

borne out in fact.<br />

A compressed air haulage installation consists<br />

essentially of the following equipment:<br />

First, suitable compressor, generally operated<br />

by steam, but which may be operated<br />

by water power or any other form of power<br />

that may be more convenient or cheaper.<br />

The method of operation of air haulage<br />

is as follows:<br />

The compressor which has<br />

a capacity of intake of cubic feet of air<br />

commensurate to the amount of output,<br />

length of haul, and grades encountered, is<br />

adjusted as to speed and maximum pressure<br />

of air, and is operated at a very nearly<br />

uniform rate during working hours. If<br />

business is slack, the compressor may be<br />

adjusted to a lower air pressure, or to deliver<br />

a lesser amount of air in a given time,<br />

:md also in its daily operation, is automatic,<br />

slowing down in speed, or increasing<br />

in speed, as may be demanded at the<br />

moment. This secures the utmost economy<br />

in the production of the compressed air<br />

which is the operating power of the locomotives.<br />

The compressor pumps the storage<br />

system of tanks, or pipe line, up to the<br />

required pressure, and, as this pressure is<br />

reached, slows down.<br />

The compressed air locomotive is connected<br />

with the charging" pipe at the station<br />

and then the air is turned on, connecting<br />

the locomotive to the line pipe.<br />

cut loose, .and start off again on<br />

another<br />

trip inside of one minute and a half.<br />

The compressed air locomotive is essentially<br />

similar to the steam locomotive; the<br />

tank holding the compressed air taking the<br />

place of the boiler on an ordinary locomotive.<br />

Some persons have had the idea that<br />

the amount of air pressure carried by a<br />

compressed air locomotive is dangerously<br />

high. The opposite is the fact, as the compressed<br />

air locomotive is much safer, so<br />

far as liability of accident is concerned, than<br />

a steam locomotive.<br />

The locomotive tank is made of heavy<br />

high tensile steel, quadruple or sextuple riveted<br />

joints, with inside and outside welt<br />

strips, with heavy steel head, hydraulically<br />

flanged. The rivet holes are drilled, the<br />

tank fitted exactly together, and the riveting<br />

done with a pressure of 150 tons. The pressure<br />

which the tank is to carry is settled<br />

before hand, and by no possibility can this<br />

pressure be exceeded. Under this system,<br />

no explosive power can possibly be developed.<br />

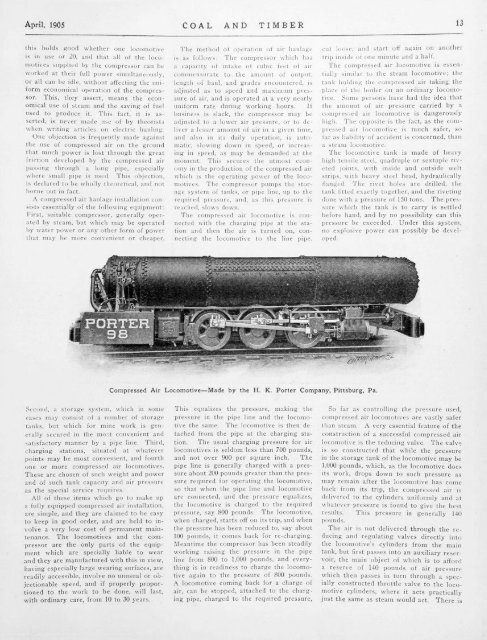

Compressed Air Locomotive—Made by the H. K. Porter Company, Pittsburg, Pa.<br />

Second, a storage system, which in some<br />

cases may consist of a number of storage<br />

tanks, but which for mine work is generally<br />

secured in the most convenient and<br />

satisfactory manner by a pipe line. Third,<br />

charging stations, situated at whatever<br />

points may be most convenient, and fourth<br />

one or more compressed air locomotives.<br />

These are chosen of such weight and power<br />

and of such tank capacity and air pressure<br />

as the special service requires.<br />

All of these items which go to make up<br />

a fully equipped compressed air installation,<br />

are simple, and they are claimed to be easy<br />

to keep in good order, and are held to involve<br />

a very low cost of permanent maintenance.<br />

The locomotives and the compressor<br />

are the only parts of the equipment<br />

which are specially liable to wear<br />

and they are manufactured with this in view,<br />

having especially large wearing surfaces, are<br />

readily accessible, involve no unusual or objectionable<br />

speed, and if properly proportioned<br />

to the work to be done, will last,<br />

with ordinary care, from 10 to 30 years.<br />

This equalizes the pressure, making the<br />

pressure in the pipe line and the locomotive<br />

the same.<br />

The locomotive is then detached<br />

from the pipe at the charging station.<br />

The usual charging pressure for air<br />

locomotives is seldom less than 700 pounds,<br />

and not over 900 per square inch. The<br />

pipe line is generally charged with a pressure<br />

about 200 pounds greater than the pressure<br />

required for operating the locomotive,<br />

so that when the pipe line and locomotive<br />

are connected, and the pressure equalizes,<br />

the locomotive is charged to the required<br />

pressure, say 800 pounds. The locomotive,<br />

when charged, starts off on its trip, and when<br />

the pressure has been reduced to, say about<br />

100 pounds, it comes back for re-charging.<br />

Meantime the compressor has been steadily<br />

working raising the pressure in the pipe<br />

line from 800 to 1,000 pounds, and everything<br />

is in readiness to charge the locomotive<br />

again to the pressure of 800 pounds.<br />

A locomotive coming back for a charge of<br />

air, can be stopped, attached to the charging<br />

pipe, charged to the required pressure,<br />

So far as controlling the pressure used,<br />

compressed air locomotives are vastly safer<br />

than steam.<br />

A very essential feature of the<br />

construction of a successful compressed air<br />

locomotive is the reducing valve. The valve<br />

is so constructed that while the pressure<br />

in the storage tank of the locomotive may be<br />

1,000 pounds, which, as the locomotive does<br />

its work, drops down to such pressure as<br />

may remain after the locomotive has come<br />

back from its trip, the compressed air is<br />

delivered to the cylinders uniformly and ;it<br />

whatever pressure is found to give the best<br />

results. This pressure is generally 140<br />

pounds.<br />

The air is not delivered through the reducing<br />

and regulating valves directly into<br />

the locomotive's cylinders from the main<br />

tank, but firstpasses into an auxiliary reservoir,<br />

the main object of which is to afford<br />

a reserve of 140 pounds of air pressure<br />

which then passes in turn through a specially<br />

constructed throttle valve to the locomotive<br />

cylinders, where it acts practically<br />

just the same as steam would act. There is