You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COAL AND TIMBER<br />

March, 1905<br />

about 8 feet long and 3 feet wide, which is<br />

so inclined towards the face by means of<br />

a trestle under the outer end that the recoil<br />

of the machine is neutralized by gravity<br />

and feeds down to the coal. The method of<br />

and slack are desirable, and the mining may<br />

be done without producing lump.<br />

When<br />

the first cut, from 4 to 5 feet wide, is finished,<br />

the board is moved across the face<br />

and another cut commenced, this shifting<br />

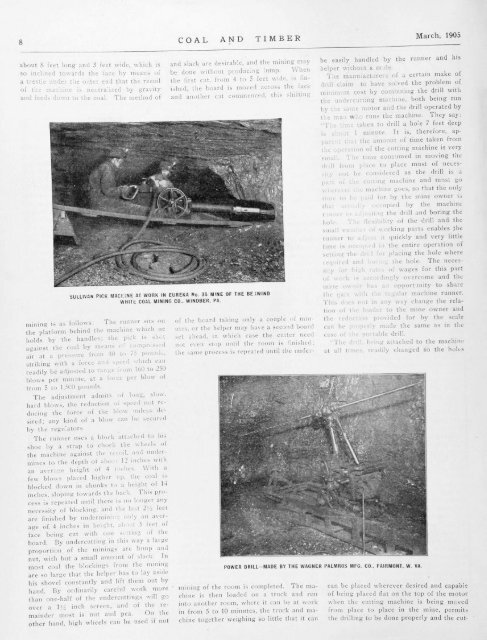

SULLIVAN PICK MACIMiNE AT WORK IN EUREKA No. 35 MINE OF THE BE.1WIND<br />

WHITE COAL MINING CO.. W1NDBER. PA.<br />

mining is as follows: The runner sits on<br />

the platform behind the machine which ne<br />

holds by the handles; the pick is sh. t<br />

against the coal by means o . impressed<br />

air at a pre,sure from 40 to 75 pounds,<br />

striking with a force and >eed .Inch can<br />

readily be adjusted to range from 160 to 250<br />

blows per minute, at a force per blow of<br />

from 5 to 1,510 pounds.<br />

The adjustment admits of long, slow.<br />

hard blows, the reduction of speed not reducing<br />

the force of the blow unless desired;<br />

any kind of a blow can be secured<br />

by the regulators.<br />

The runner uses a block attached to his<br />

shoe by a strap to chock the wheels oi<br />

the machine against the recoil, and undermines<br />

to the depth of abo: 12 niche, with<br />

an average height of 4 i iches. With a<br />

few blows placed higher up, the coal is<br />

blocked down in chunks to a height ol 14<br />

inches, sloping towards the back. Tins process<br />

is repeated until there is no longer any<br />

necessity of blocking, and the last JJ feet<br />

are finished by underminii only an average<br />

of. 4 inches in height, about 5 feet of<br />

face being cut with one -King of the<br />

board. By undercutting in this way a large<br />

proportion of the minings are lump and<br />

nut, with but a small amount of slack. In<br />

most coal the blockings from tlie mining<br />

are so large that the helper has to lay aside<br />

his shovel constantly and lift them out by<br />

hand. By ordinarily careful work more<br />

than one-half of the undercuttings will go<br />

over a VJi, inch screen, and of the remainder<br />

most is nut and pea. On the<br />

other hand, high wheels can be used if nut<br />

of the board taking only a couple of minutes,<br />

or the helper may have a second board<br />

set ahead, in which case the cutter need<br />

not even stop until the room is finished;<br />

the same process is repeated until the underlie<br />

easily handled by the runner and his<br />

helper without a mule.<br />

The manufacturers of a certain make of<br />

drill claim to have solved the problem of<br />

minimum cost by combining the drill with<br />

the undercutting machine, both being run<br />

by the same motor and the drill operated by<br />

the man who runs the machine. They say:<br />

e taken to drill a hole 7 feet deep<br />

about 1 minute. It is, therefore, apt<br />

the amount of time taken from<br />

leration of the cutting machine is very<br />

The time consumed in moving the<br />

drill from place to place must of neces-<br />

3jlj not be considered as the drill is a<br />

part 0] cutting machine and must go<br />

machine goes, so that the only<br />

I for by the mine owner is<br />

th, | occupied by the machine<br />

runner i<br />

die drill and boring the<br />

| 101 i ' flexibility of the drill and the<br />

small ,,u<br />

orking parts enables the<br />

runner to idjusl it quickly and very little<br />

time is o<br />

the entire operation of<br />

ig the dn 1 for placing the hole where<br />

required and I the hole. The necessity<br />

or high rate of wages for this part<br />

of work is ccordingly overcome and the<br />

mine owner hi - a i opportunity to share<br />

the gain with I liar machine runner.<br />

This does not in any way change the relation<br />

of the loader to the mine owner and<br />

the reduction provided for by the scale<br />

can be properly made the same as in tke<br />

case of the portable drill.<br />

"The drill, being attached to the machine<br />

at all times, readily changed so the holes<br />

POWER DRILL-MADE BY THE WAGNER PALMROS MFG. CO.. FAIRMONT. W. VA.<br />

milling of the room is completed. The machine<br />

is then loaded on a truck and run<br />

into another room, where it can be at work<br />

in from 5 to 10 minutes, the truck and machine<br />

together weighing so little that it can<br />

can be placed wherever desired and capable<br />

of being placed flat on the top of the motor<br />

when the cutting machine is being moved<br />

from place to place in the mine, permits<br />

the drilling to be done properly and the cut-