You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

February, 1905 COAL AND TIMBER 15<br />

bills comparatively light. On account of<br />

the coal being carried the full length of the<br />

hopper before being pushed into the car,<br />

the breakage of coal is very slight. One<br />

objection raised by a company using a<br />

number of these loaders is that the coal<br />

is not pushed far enough into the ends<br />

of long box cars, on account of which fact<br />

it is impossible to load them to their rated<br />

capacity. This difficuhty has been overcome<br />

in the latest machines which have<br />

longer hoppers than the earlier ones.<br />

An Illinois mining engineer wrote: "The<br />

coal at this mine is delivered to the loader<br />

by a shaking screen and it works admirably,<br />

with very light repair bills. It is<br />

the only loader with which I am familiar<br />

which allows the pickers to get into the car<br />

and pick the impurities out of the coal<br />

while loading at alternate ends. It will<br />

handle all the coal delivered to it by a large<br />

shaking screen. I should rate its capacity<br />

at from 100 to 125 tons per hour." The<br />

general manager of the largest coal company<br />

in West Virginia wrote: "We have<br />

several of these loaders in use, and our<br />

experience with them has been decidely<br />

satisfactory. We load from 20 to 25 box<br />

cars a day with each loader. The cost of<br />

repairs at one mine at which we have kept<br />

an accurate record amounts to about $8 to<br />

$10 per month." The superintendent of a<br />

Maryland Company wrote: "Our Ottumwa<br />

loaders have been doing very satisfactory<br />

work, although they require considerable<br />

expenditure for repairs. This<br />

item has not been so heavy recently as<br />

heretofore on account of improvements<br />

made, but even at its worst, the machine<br />

effected a very decided economy as compared<br />

with loading by hand. If everything<br />

is working right, we can count on<br />

loading about one car in 25 minutes. They<br />

break ihe coal very little." The superintendent<br />

of the mining department of one<br />

ot the western railroads, in discussing the<br />

OttMimwa loader at one of their Wyoming<br />

mines, wrote: "We have been using this<br />

loader for a number of years and believe<br />

it lo be superior to any other loader on<br />

the market. The first loaders we had were<br />

continually breaking down and causing a<br />

great many deiays, but since then most of<br />

the parts have been made heavier and reinforced<br />

so that breakage is reduced to a<br />

minimum We still have breakdowns, but<br />

they are caused mostly by loading small<br />

cars to large capacity when the loader has<br />

to force the coal into the ends of the cars.<br />

About 1000 tons per day is what the loader<br />

can. handle without very much cost for<br />

repairs. It does not break the coal much,<br />

except in cases where the cars are small<br />

for their rated capacities, and then in<br />

crowding the coal back, there is some slack<br />

made by the constant grinding of the hopper<br />

and chain on the coal."<br />

The Christy loader, invented by J. M.<br />

Christy of Des Moines, Iowa, and manufactured<br />

by the Christy Box Car Loader<br />

Co., of that city, was the first successful<br />

loader which operated by throwing the coal<br />

into the car from an endless conveyor.<br />

The first loader was installed at a Des<br />

Moines mine in 1898 and the second at the<br />

Divernon, 111., mine of the Madison Coal<br />

Co. One hundred of these loaders have<br />

been placed on the market since 1900.<br />

Numerous changes and improvements have<br />

been made and the "Christy" is now recognized<br />

as one of the few really successful<br />

types of loaders. It is made to run with<br />

either steam or electricity.<br />

Ihe Christy loader is built on a movable<br />

platform consisting of a pair of 10 inch I<br />

beams 15 feet long carried on four 12 inch<br />

wheels, which are keyed to two 2V; inch<br />

axles and run on a pair of rails set 40 inches<br />

apart. The long axis of the platform and<br />

the rails upon which it moves, are perpendicular<br />

to the track upon which the box cars<br />

are loaded, and the platform rests upon a<br />

timber foundation of sufficient height to<br />

bring the bottom of the I beams a little<br />

above the height of the bottom of a car.<br />

The engines or dynamo are securely<br />

bolted to the 1 beams at the inner end of<br />

the platform and a conveyor or loading<br />

belt is located at the outer end. In the<br />

steam machines, a pair of 10"x8" reversible<br />

Christy engines are connected to a 3 inch<br />

shaft running the full length of the platform<br />

between the I beams, while in the<br />

electric machine a 50 H.-P. Western<br />

Electric Co. motor wound for 220, 250 or<br />

500 volts is geared to the shaft. In either<br />

style of machine the platform is moved<br />

forward and back a sufficient distance to<br />

place the loading belt in a car or to remove<br />

it, by bringing a bevel gear on the main<br />

shaft into play with one on the front axle<br />

of the platform, motion being produced by<br />

traction.<br />

The loading belt is 8 feet long over all,<br />

30 inches wide, and at the center is 354<br />

feet above the rails upon which the platform<br />

moves, but curves upwards at each<br />

end. Tts sides are heavy sheet steel and<br />

support three shafts, one at the center and<br />

one at each end. The center shaft is<br />

geared to the main engine or dynamo shaft,<br />

and by means of a link chain and sprockets<br />

Mit the rear of the belt, drives one of the<br />

end shafts. Each end shaft carries a pair<br />

of 17>/j inch sprocket wheels around which<br />

pass two endless link chains. To these<br />

chains are bolted l / 2"x3}4" steel plates, 30<br />

inches long, and 2 inch angle irons are<br />

fastened to the belt at intervals of 2 feet.<br />

The belt being too long to pass through a<br />

car door when in position to load, is turned<br />

on its pivoted support through an angle of<br />

90 degrees by means of a 4'x6" steam<br />

cylinder in the steam machine or a 4'x2"<br />

screw in the electric machine. The entire<br />

platform is then moved forward on its<br />

wheels until the belt is inside the car,<br />

when the cylinder or screw returns the belt<br />

to a position in line with the car. Two<br />

5"X3J/MM" angle irons, just above the platform<br />

wheels on each side, hold the loader<br />

in eqiulibrium in all positions.<br />

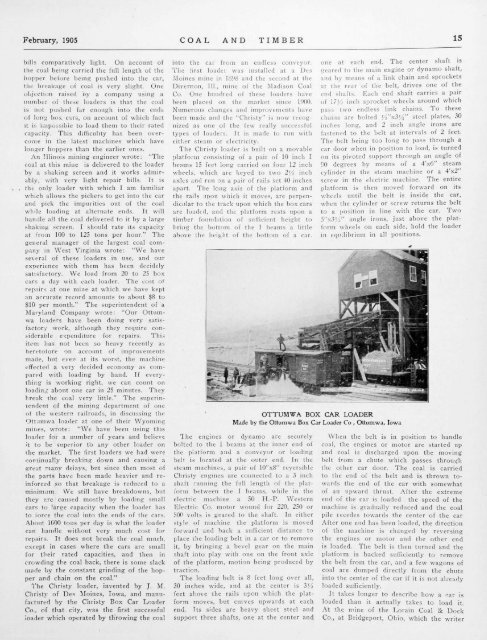

OTTUMWA BOX CAR LOADER<br />

Made by the Ottumwa Box Car Loader Co , Ottumwa, Iowa<br />

When the belt is in position to handle<br />

coal, the engines or motor are started up<br />

and coal is discharged upon the moving<br />

belt from a chute which passes through<br />

the other car door. The coal is carried<br />

to the end of the belt and is thrown towards<br />

the end of the car with somewhat<br />

of an upward thrust. After the extreme<br />

end of the car is loaded the speed of the<br />

machine is gradually reduced and the coal<br />

pile recedes towards the center of the car<br />

After one end has been loaded, the direction<br />

ol the machine is changed by reversing<br />

the engines or motor and the other end<br />

is loaded. The belt is then turned and the<br />

platform is backed sufficiently to remove<br />

the belt from the car, and a few wagons of<br />

coal are dumped directly from the chute<br />

into the center of the car if it is not already<br />

loaded sufficiently.<br />

It takes longer to describe how a car is<br />

loaded than it actually takes to load it.<br />

At the m.ine of the Lorain Coal & Dock<br />

Co., at Bridgeport, Ohio, which the writer