Insurance Discount May Pay for Your BPPP Training - American ...

Insurance Discount May Pay for Your BPPP Training - American ...

Insurance Discount May Pay for Your BPPP Training - American ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

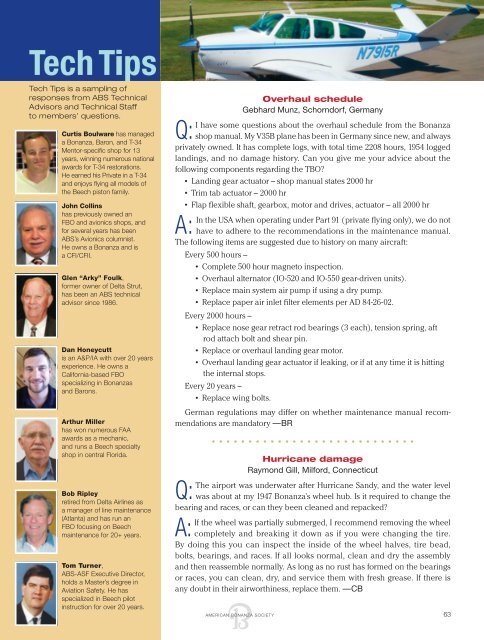

Tech Tips<br />

Tech Tips is a sampling of<br />

responses from ABS Technical<br />

Advisors and Technical Staff<br />

to members’ questions.<br />

Curtis Boulware has managed<br />

a Bonanza, Baron, and T-34<br />

Mentor-specific shop <strong>for</strong> 13<br />

years, winning numerous national<br />

awards <strong>for</strong> T-34 restorations.<br />

He earned his Private in a T-34<br />

and enjoys flying all models of<br />

the Beech piston family.<br />

John Collins<br />

has previously owned an<br />

FBO and avionics shops, and<br />

<strong>for</strong> several years has been<br />

ABS’s Avionics columnist.<br />

He owns a Bonanza and is<br />

a CFI/CFII.<br />

Glen “Arky” Foulk,<br />

<strong>for</strong>mer owner of Delta Strut,<br />

has been an ABS technical<br />

advisor since 1986.<br />

Dan Honeycutt<br />

is an A&P/IA with over 20 years<br />

experience. He owns a<br />

Cali<strong>for</strong>nia-based FBO<br />

specializing in Bonanzas<br />

and Barons.<br />

Arthur Miller<br />

has won numerous FAA<br />

awards as a mechanic,<br />

and runs a Beech specialty<br />

shop in central Florida.<br />

Bob Ripley<br />

retired from Delta Airlines as<br />

a manager of line mainte nance<br />

(Atlanta) and has run an<br />

FBO focusing on Beech<br />

maintenance <strong>for</strong> 20+ years.<br />

Tom Turner,<br />

ABS-ASF Executive Director,<br />

holds a Master’s degree in<br />

Aviation Safety. He has<br />

specialized in Beech pilot<br />

instruction <strong>for</strong> over 20 years.<br />

Overhaul schedule<br />

Gebhard Munz, Schorndorf, Germany<br />

I have some questions about the overhaul schedule from the Bonanza<br />

Q: shop manual. My V35B plane has been in Germany since new, and always<br />

privately owned. It has complete logs, with total time 2208 hours, 1954 logged<br />

landings, and no damage history. Can you give me your advice about the<br />

following components regarding the TBO?<br />

x Landing gear actuator – shop manual states 2000 hr<br />

x Trim tab actuator – 2000 hr<br />

x Flap flexible shaft, gearbox, motor and drives, actuator – all 2000 hr<br />

A:<br />

In the USA when operating under Part 91 (private flying only), we do not<br />

have to adhere to the recommendations in the maintenance manual.<br />

The following items are suggested due to history on many aircraft:<br />

Every 500 hours –<br />

x Complete 500 hour magneto inspection.<br />

x Overhaul alternator (IO-520 and IO-550 gear-driven units).<br />

x Replace main system air pump if using a dry pump.<br />

x Replace paper air inlet filter elements per AD 84-26-02.<br />

Every 2000 hours –<br />

x Replace nose gear retract rod bearings (3 each), tension spring, aft<br />

rod attach bolt and shear pin.<br />

x Replace or overhaul landing gear motor.<br />

x Overhaul landing gear actuator if leaking, or if at any time it is hitting<br />

the internal stops.<br />

Every 20 years –<br />

x Replace wing bolts.<br />

German regulations may differ on whether maintenance manual recommendations<br />

are mandatory —BR<br />

Q:<br />

A:<br />

Hurricane damage<br />

Raymond Gill, Mil<strong>for</strong>d, Connecticut<br />

The airport was underwater after Hurricane Sandy, and the water level<br />

was about at my 1947 Bonanza’s wheel hub. Is it required to change the<br />

bearing and races, or can they been cleaned and repacked?<br />

If the wheel was partially submerged, I recommend removing the wheel<br />

completely and breaking it down as if you were changing the tire.<br />

By doing this you can inspect the inside of the wheel halves, tire bead,<br />

bolts, bearings, and races. If all looks normal, clean and dry the assembly<br />

and then reassemble normally. As long as no rust has <strong>for</strong>med on the bearings<br />

or races, you can clean, dry, and service them with fresh grease. If there is<br />

any doubt in their airworthiness, replace them. —CB<br />

AMERICAN BONANZA SOCIETY 63