Part II - IPA SA

Part II - IPA SA

Part II - IPA SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

38 REVISTA ROMÂN DE AUTOMATIC<br />

dedicated systems developed by<br />

acknowledged companies for the special<br />

monitoring domains such as vibrations and<br />

partial discharges.<br />

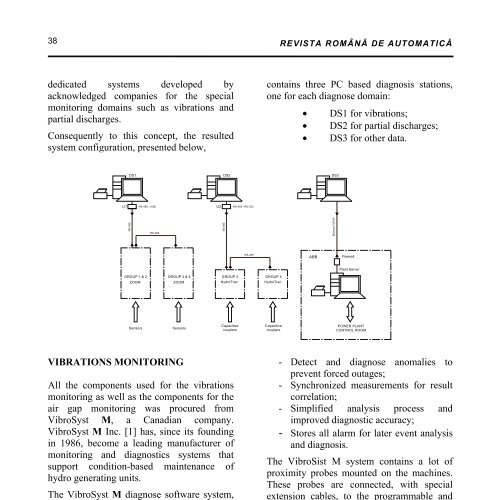

Consequently to this concept, the resulted<br />

system configuration, presented below,<br />

contains three PC based diagnosis stations,<br />

one for each diagnose domain:<br />

• DS1 for vibrations;<br />

• DS2 for partial discharges;<br />

• DS3 for other data.<br />

DS1<br />

DS2<br />

DS3<br />

U1 RS-485 / USB U2 RS-485 / RS-232<br />

RS-485<br />

RS-485<br />

RS-485<br />

Ethernet TCP/IP<br />

RS-485<br />

ABB<br />

Firewall<br />

Plant Server<br />

GROUP 1 & 2 GROUP 3 & 4<br />

ZOOM<br />

ZOOM<br />

GROUP 3 GROUP 4<br />

HydroTrac<br />

HydroTrac<br />

Sensors<br />

Sensors<br />

Capacitive<br />

couplers<br />

Capacitive<br />

couplers<br />

POWER PLANT<br />

CONTROL ROOM<br />

VIBRATIONS MONITORING<br />

All the components used for the vibrations<br />

monitoring as well as the components for the<br />

air gap monitoring was procured from<br />

VibroSyst M, a Canadian company.<br />

VibroSyst M Inc. [1] has, since its founding<br />

in 1986, become a leading manufacturer of<br />

monitoring and diagnostics systems that<br />

support condition-based maintenance of<br />

hydro generating units.<br />

The VibroSyst M diagnose software system,<br />

named “ZOOM” (Zero Outage On-line<br />

Monitoring) was adopted for monitoring and<br />

diagnostics acquisition of hydro generating<br />

units. The ZOOM System is easy to use,<br />

simplifies measurement procedures,<br />

facilitates behavior analysis and warns the<br />

user of alarm conditions.<br />

The ZOOM System database assures<br />

improved operations and maintenance of<br />

hydro generators, increasing its service<br />

availability and producing significant<br />

savings. The system represents an powerful<br />

analytical and diagnostic tool which:<br />

- Detect and diagnose anomalies to<br />

prevent forced outages;<br />

- Synchronized measurements for result<br />

correlation;<br />

- Simplified analysis process and<br />

improved diagnostic accuracy;<br />

- Stores all alarm for later event analysis<br />

and diagnosis.<br />

The VibroSist M system contains a lot of<br />

proximity probes mounted on the machines.<br />

These probes are connected, with special<br />

extension cables, to the programmable and<br />

monitoring units logged by <strong>IPA</strong> in two<br />

cabinets near the hydro generator units: one<br />

cabinet for group 1 and group 2 and another<br />

cabinet for group 3 and group 4. These two<br />

cabinets are connected via RS-485 network to<br />

the DS1 diagnosis station which is loaded<br />

with the ZOOM software.<br />

The monitoring refers to the shaft relative<br />

vibration, the bearing absolute vibration and<br />

the generator air gap correlated with a<br />

synchro probe.