Tender Specification for Supply, Erection, Testing and ... - IDCO

Tender Specification for Supply, Erection, Testing and ... - IDCO

Tender Specification for Supply, Erection, Testing and ... - IDCO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DOUBLE SKINNED CASING:<br />

The casing shall be self supporting type, factory fabricated <strong>and</strong> assembled made of extruded<br />

anodised aluminum hollow sections to make a rigid frame structure. The frame shall be assembled<br />

using pressure die cast aluminum joints. The self supporting unit shall consist of s<strong>and</strong>wiched panel<br />

made out of 0.6mm thick pre-plasticide sheet outside <strong>and</strong> 0.6mm GI sheet inside duly factory<br />

fabricated insulated with 23 mm thick injected PU foam insulation of density of 30 Kg/CMT in between<br />

(As specified in Bill of Quantities). The insulated panels shall be bolted to main frame with<br />

neoprene rubber gaskets held captive in the framed extrusion to make it leak proof. Suitable air tight<br />

access doors / panels with pressure die cast aluminum hinges <strong>and</strong> nylon h<strong>and</strong>les <strong>and</strong> locks shall be<br />

provided <strong>for</strong> access to various sections <strong>for</strong> maintenance. The entire housing shall be mounted on<br />

Extruded Aluminum channel frame work having pressure die cast aluminum jointers or the frame<br />

work shall be joined together with corner plates. Condensate Drain Pan shall be constructed of 22<br />

gauge Stainless steel sheet with all corners welded with uni<strong>for</strong>m slope from all sides leading to drain<br />

pan ensuring no stagnation of condensate water.<br />

SINGLE SKINNED CASING:<br />

The casing shall be self supporting type, factory fabricated & assembled made of extruded anodised<br />

aluminum hollow sections to make a rigid frame structure. The frame shall be assembled using<br />

pressure die cast aluminum joints. The self supporting unit shall consist of 18 G pre-plasticide / precoated<br />

GI sheet body factory fabricated. The AHU casing shall be insulated with with 23 mm thick<br />

injected PU foam insulation of density of 30 Kg/CMT from inside. The casing shall be bolted to main<br />

frame with neoprene rubber gaskets held captive in the framed extrusion to make it leak proof.<br />

Suitable air tight access doors / panels with pressure die cast aluminum hinges & nylon h<strong>and</strong>les <strong>and</strong><br />

locks shall be provided <strong>for</strong> access to various sections <strong>for</strong> maintenance. The Entire housing shall be<br />

mounted on Extruded Aluminum channel frame work having pressure die cast aluminum jointers or<br />

the frame work shall be joined together with corner plates Condensate. Drain Pan shall be<br />

constructed of 22 gauge polished stainless steel sheet with all corners welded with uni<strong>for</strong>m slope<br />

from all sides leading to drain pan ensuring no stagnation of condensate water. Drain Pan shall be<br />

insulated with 10 mm thick nitrile foam.<br />

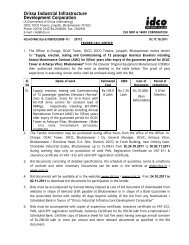

MOTOR AND DRIVE:<br />

The fan motors shall be 415 ± 10% volts, 50 ± 5 % HZ, 3 phase TEFC SQ. Cage induction motor.<br />

The motor shall be specially designed <strong>for</strong> quiet operation & motor speed shall not exceed 1440 RPM.<br />

Drive to fan shall be provided through belt drive arrangement. Belts shall be of the resistant type only.<br />

FAN OF DOUBLE/ SINGLE SKINNED AIRHANDLING UNITS:<br />

The casing shall have heavy gauge GI construction <strong>for</strong>ward curved DIDW fan statically <strong>and</strong><br />

dynamically balanced mounted on EN8 solid shaft or C 40 carbon steel. The supply air DIDW fan<br />

shall be <strong>for</strong>ward curved. The fan impeller shall be supported to housing with angle iron frame <strong>and</strong><br />

pillow block heavy duty ball bearing. The fan shall be selected <strong>for</strong> a fan speed not exceeding 1000<br />

RPM. <strong>and</strong> fan outlet velocity shall be below 10.2 meter / sec. The fan housing with TEFC Sq. Cage<br />

motor shall be mounted on a common adjustable base frame on vibration isolators in case the<br />

impeller diameter is exceeding 450 mm <strong>and</strong> rubber turret mounts vibration isolators <strong>for</strong> fan diameter<br />

up to 450mm diameter. The fan motor shall be installed inside the housing of air h<strong>and</strong>ling unit to keep<br />

low noise level. The assembly <strong>for</strong> fan <strong>and</strong> motor shall be of aluminum extruded section only.