NuMi Off-Axis Neutrino Appearance - NOVA Document Database ...

NuMi Off-Axis Neutrino Appearance - NOVA Document Database ...

NuMi Off-Axis Neutrino Appearance - NOVA Document Database ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

• The task manager illustrated high-quality connection to the schedules.<br />

• Manpower appears to be adequate to receive CD-2 approval. The project realizes the<br />

need to hire the first factory manager immediately.<br />

• Structural analysis support appears thin and the project should evaluate the<br />

engineering manpower profile between the R&D and production phases for<br />

continuity.<br />

Time and motion studies for some assembly steps were very well done, but are incomplete.<br />

The routing of the fiber into the manifold is advanced, as is the testing plans for the modules<br />

through their various phases of construction. A similarly thorough assessment for all phases of<br />

module assembly is needed for CD-2. The prototype effort scheduled for this summer should<br />

provide significant insight into the steps necessary to properly assemble and test functional<br />

modules. The prototyping effort should include time and motion definition as one of its<br />

objectives.<br />

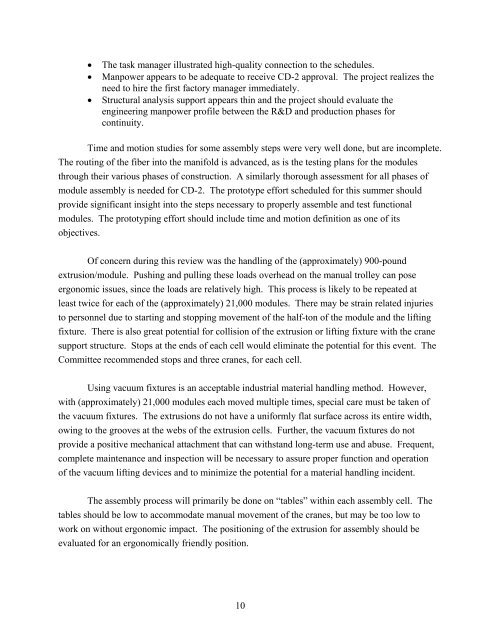

Of concern during this review was the handling of the (approximately) 900-pound<br />

extrusion/module. Pushing and pulling these loads overhead on the manual trolley can pose<br />

ergonomic issues, since the loads are relatively high. This process is likely to be repeated at<br />

least twice for each of the (approximately) 21,000 modules. There may be strain related injuries<br />

to personnel due to starting and stopping movement of the half-ton of the module and the lifting<br />

fixture. There is also great potential for collision of the extrusion or lifting fixture with the crane<br />

support structure. Stops at the ends of each cell would eliminate the potential for this event. The<br />

Committee recommended stops and three cranes, for each cell.<br />

Using vacuum fixtures is an acceptable industrial material handling method. However,<br />

with (approximately) 21,000 modules each moved multiple times, special care must be taken of<br />

the vacuum fixtures. The extrusions do not have a uniformly flat surface across its entire width,<br />

owing to the grooves at the webs of the extrusion cells. Further, the vacuum fixtures do not<br />

provide a positive mechanical attachment that can withstand long-term use and abuse. Frequent,<br />

complete maintenance and inspection will be necessary to assure proper function and operation<br />

of the vacuum lifting devices and to minimize the potential for a material handling incident.<br />

The assembly process will primarily be done on “tables” within each assembly cell. The<br />

tables should be low to accommodate manual movement of the cranes, but may be too low to<br />

work on without ergonomic impact. The positioning of the extrusion for assembly should be<br />

evaluated for an ergonomically friendly position.<br />

10