EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.3 Fasti System<br />

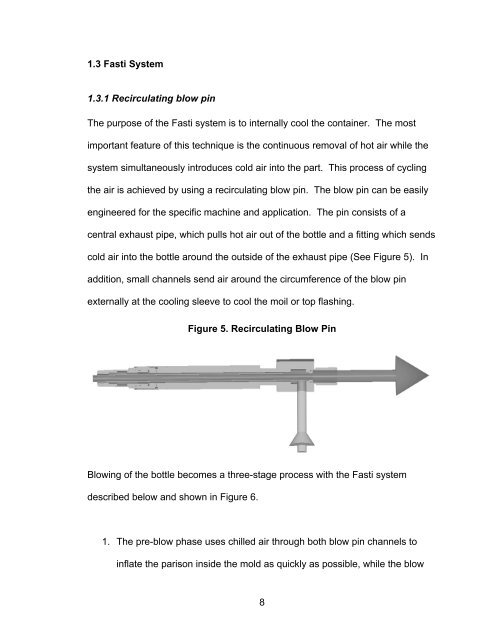

1.3.1 Recirculating blow pin<br />

The purpose of the Fasti system is to internally cool the container. The most<br />

important feature of this technique is the continuous removal of hot air while the<br />

system simultaneously introduces cold air into the part. This process of cycling<br />

the air is achieved by using a recirculating blow pin. The blow pin can be easily<br />

engineered for the specific machine and application. The pin consists of a<br />

central exhaust pipe, which pulls hot air out of the bottle and a fitting which sends<br />

cold air into the bottle around the outside of the exhaust pipe (See Figure 5). In<br />

addition, small channels send air around the circumference of the blow pin<br />

externally at the cooling sleeve to cool the moil or top flashing.<br />

Figure 5. Recirculating Blow Pin<br />

Blowing of the bottle becomes a three-stage process with the Fasti system<br />

described below and shown in Figure 6.<br />

1. The pre-blow phase uses chilled air through both blow pin channels to<br />

inflate the parison inside the mold as quickly as possible, while the blow<br />

8