EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

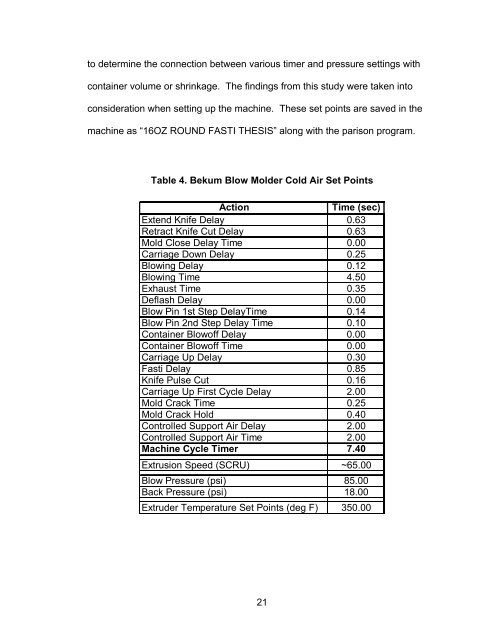

to determine the connection between various timer and pressure settings with<br />

container volume or shrinkage. The findings from this study were taken into<br />

consideration when setting up the machine. These set points are saved in the<br />

machine as “16OZ ROUND FASTI THESIS” along with the parison program.<br />

Table 4. Bekum Blow Molder Cold Air Set Points<br />

Action<br />

Time (sec)<br />

Extend Knife Delay 0.63<br />

Retract Knife Cut Delay 0.63<br />

Mold Close Delay Time 0.00<br />

Carriage Down Delay 0.25<br />

Blowing Delay 0.12<br />

Blowing Time 4.50<br />

Exhaust Time 0.35<br />

Deflash Delay 0.00<br />

Blow Pin 1st Step DelayTime 0.14<br />

Blow Pin 2nd Step Delay Time 0.10<br />

Container Blowoff Delay 0.00<br />

Container Blowoff Time 0.00<br />

Carriage Up Delay 0.30<br />

Fasti Delay 0.85<br />

Knife Pulse Cut 0.16<br />

Carriage Up First Cycle Delay 2.00<br />

Mold Crack Time 0.25<br />

Mold Crack Hold 0.40<br />

Controlled Support Air Delay 2.00<br />

Controlled Support Air Time 2.00<br />

Machine Cycle Timer 7.40<br />

Extrusion Speed (SCRU) ~65.00<br />

Blow Pressure (psi) 85.00<br />

Back Pressure (psi) 18.00<br />

Extruder Temperature Set Points (deg F) 350.00<br />

21