EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

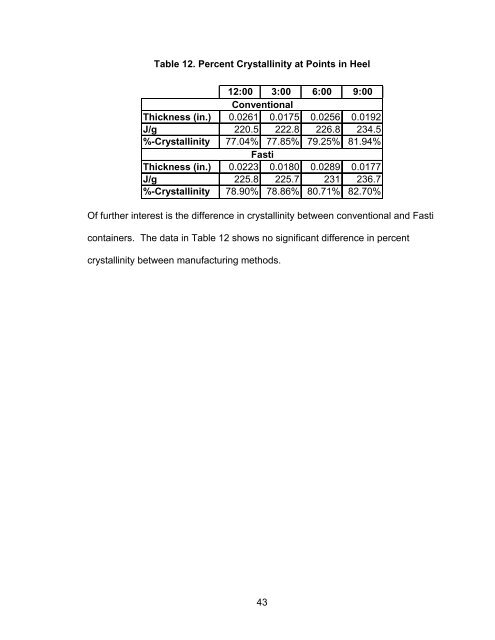

Table 12. Percent Crystallinity at Points in Heel<br />

12:00 3:00 6:00 9:00<br />

Conventional<br />

Thickness (in.) 0.0261 0.0175 0.0256 0.0192<br />

J/g 220.5 222.8 226.8 234.5<br />

%-Crystallinity 77.04% 77.85% 79.25% 81.94%<br />

Fasti<br />

Thickness (in.) 0.0223 0.0180 0.0289 0.0177<br />

J/g 225.8 225.7 231 236.7<br />

%-Crystallinity 78.90% 78.86% 80.71% 82.70%<br />

Of further interest is the difference in crystallinity between conventional and Fasti<br />

containers. The data in Table 12 shows no significant difference in percent<br />

crystallinity between manufacturing methods.<br />

43