EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

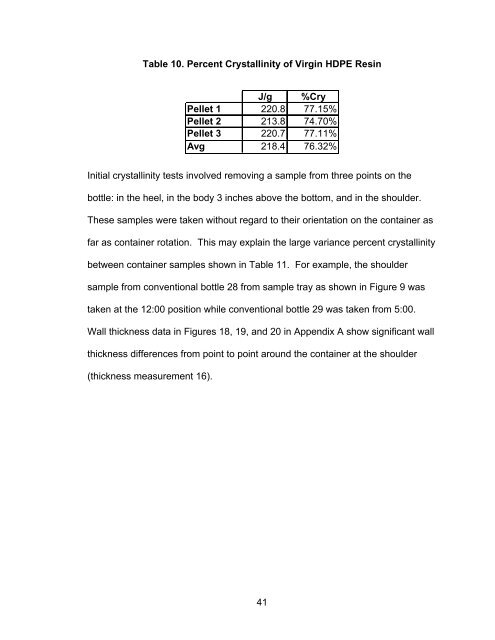

Table 10. Percent Crystallinity of Virgin HDPE Resin<br />

J/g %Cry<br />

Pellet 1 220.8 77.15%<br />

Pellet 2 213.8 74.70%<br />

Pellet 3 220.7 77.11%<br />

Avg 218.4 76.32%<br />

Initial crystallinity tests involved removing a sample from three points on the<br />

bottle: in the heel, in the body 3 inches above the bottom, and in the shoulder.<br />

These samples were taken without regard to their orientation on the container as<br />

far as container rotation. This may explain the large variance percent crystallinity<br />

between container samples shown in Table 11. For example, the shoulder<br />

sample from conventional bottle 28 from sample tray as shown in Figure 9 was<br />

taken at the 12:00 position while conventional bottle 29 was taken from 5:00.<br />

Wall thickness data in Figures 18, 19, and 20 in Appendix A show significant wall<br />

thickness differences from point to point around the container at the shoulder<br />

(thickness measurement 16).<br />

41