EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

EFFECTS OF EXTRUSION BLOW MOLDING INTERNAL COOLING ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

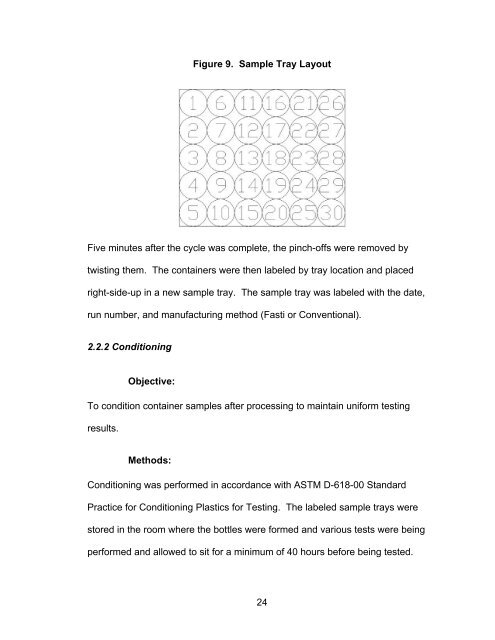

Figure 9. Sample Tray Layout<br />

Five minutes after the cycle was complete, the pinch-offs were removed by<br />

twisting them. The containers were then labeled by tray location and placed<br />

right-side-up in a new sample tray. The sample tray was labeled with the date,<br />

run number, and manufacturing method (Fasti or Conventional).<br />

2.2.2 Conditioning<br />

Objective:<br />

To condition container samples after processing to maintain uniform testing<br />

results.<br />

Methods:<br />

Conditioning was performed in accordance with ASTM D-618-00 Standard<br />

Practice for Conditioning Plastics for Testing. The labeled sample trays were<br />

stored in the room where the bottles were formed and various tests were being<br />

performed and allowed to sit for a minimum of 40 hours before being tested.<br />

24