Technical Development of Waste Sector in Sweden: Survey

Technical Development of Waste Sector in Sweden: Survey

Technical Development of Waste Sector in Sweden: Survey

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MASTER’S THESIS IN ENVIRONMENTAL STRATEGIES RESEARCH<br />

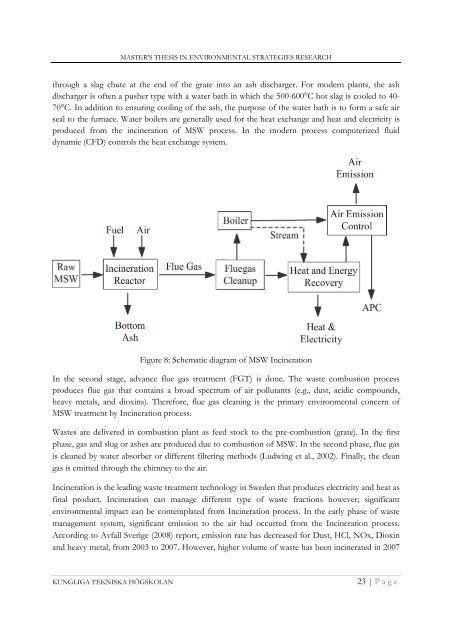

through a slag chute at the end <strong>of</strong> the grate <strong>in</strong>to an ash discharger. For modern plants, the ash<br />

discharger is <strong>of</strong>ten a pusher type with a water bath <strong>in</strong> which the 500-600°C hot slag is cooled to 40-<br />

70°C. In addition to ensur<strong>in</strong>g cool<strong>in</strong>g <strong>of</strong> the ash, the purpose <strong>of</strong> the water bath is to form a safe air<br />

seal to the furnace. Water boilers are generally used for the heat exchange and heat and electricity is<br />

produced from the <strong>in</strong>c<strong>in</strong>eration <strong>of</strong> MSW process. In the modern process computerized fluid<br />

dynamic (CFD) controls the heat exchange system.<br />

Figure 8: Schematic diagram <strong>of</strong> MSW Inc<strong>in</strong>eration<br />

In the second stage, advance flue gas treatment (FGT) is done. The waste combustion process<br />

produces flue gas that conta<strong>in</strong>s a broad spectrum <strong>of</strong> air pollutants (e.g., dust, acidic compounds,<br />

heavy metals, and diox<strong>in</strong>s). Therefore, flue gas clean<strong>in</strong>g is the primary environmental concern <strong>of</strong><br />

MSW treatment by Inc<strong>in</strong>eration process.<br />

<strong>Waste</strong>s are delivered <strong>in</strong> combustion plant as feed stock to the pre-combustion (grate). In the first<br />

phase, gas and slug or ashes are produced due to combustion <strong>of</strong> MSW. In the second phase, flue gas<br />

is cleaned by water absorber or different filter<strong>in</strong>g methods (Ludw<strong>in</strong>g et al., 2002). F<strong>in</strong>ally, the clean<br />

gas is emitted through the chimney to the air.<br />

Inc<strong>in</strong>eration is the lead<strong>in</strong>g waste treatment technology <strong>in</strong> <strong>Sweden</strong> that produces electricity and heat as<br />

f<strong>in</strong>al product. Inc<strong>in</strong>eration can manage different type <strong>of</strong> waste fractions however; significant<br />

environmental impact can be contemplated from Inc<strong>in</strong>eration process. In the early phase <strong>of</strong> waste<br />

management system, significant emission to the air had occurred from the Inc<strong>in</strong>eration process.<br />

Accord<strong>in</strong>g to Avfall Sverige (2008) report, emission rate has decreased for Dust, HCl, NOx, Diox<strong>in</strong><br />

and heavy metal, from 2003 to 2007. However, higher volume <strong>of</strong> waste has been <strong>in</strong>c<strong>in</strong>erated <strong>in</strong> 2007<br />

KUNGLIGA TEKNISKA HÖGSKOLAN<br />

23 | Page