Technical Development of Waste Sector in Sweden: Survey

Technical Development of Waste Sector in Sweden: Survey

Technical Development of Waste Sector in Sweden: Survey

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MASTER’S THESIS IN ENVIRONMENTAL STRATEGIES RESEARCH<br />

particulates from the pyrolysis/gasification processes. However, the emission <strong>of</strong> oxides <strong>of</strong> nitrogen,<br />

VOCs and diox<strong>in</strong>s might be similar with the other thermal waste treatment technology (DEFRA,<br />

2004).<br />

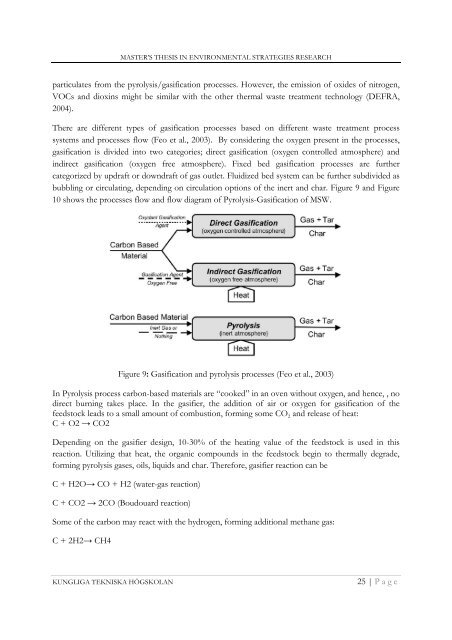

There are different types <strong>of</strong> gasification processes based on different waste treatment process<br />

systems and processes flow (Feo et al., 2003). By consider<strong>in</strong>g the oxygen present <strong>in</strong> the processes,<br />

gasification is divided <strong>in</strong>to two categories; direct gasification (oxygen controlled atmosphere) and<br />

<strong>in</strong>direct gasification (oxygen free atmosphere). Fixed bed gasification processes are further<br />

categorized by updraft or downdraft <strong>of</strong> gas outlet. Fluidized bed system can be further subdivided as<br />

bubbl<strong>in</strong>g or circulat<strong>in</strong>g, depend<strong>in</strong>g on circulation options <strong>of</strong> the <strong>in</strong>ert and char. Figure 9 and Figure<br />

10 shows the processes flow and flow diagram <strong>of</strong> Pyrolysis-Gasification <strong>of</strong> MSW.<br />

Figure 9: Gasification and pyrolysis processes (Feo et al., 2003)<br />

In Pyrolysis process carbon-based materials are “cooked” <strong>in</strong> an oven without oxygen, and hence, , no<br />

direct burn<strong>in</strong>g takes place. In the gasifier, the addition <strong>of</strong> air or oxygen for gasification <strong>of</strong> the<br />

feedstock leads to a small amount <strong>of</strong> combustion, form<strong>in</strong>g some CO 2 and release <strong>of</strong> heat:<br />

C + O2 → CO2<br />

Depend<strong>in</strong>g on the gasifier design, 10-30% <strong>of</strong> the heat<strong>in</strong>g value <strong>of</strong> the feedstock is used <strong>in</strong> this<br />

reaction. Utiliz<strong>in</strong>g that heat, the organic compounds <strong>in</strong> the feedstock beg<strong>in</strong> to thermally degrade,<br />

form<strong>in</strong>g pyrolysis gases, oils, liquids and char. Therefore, gasifier reaction can be<br />

C + H2O→ CO + H2 (water-gas reaction)<br />

C + CO2 → 2CO (Boudouard reaction)<br />

Some <strong>of</strong> the carbon may react with the hydrogen, form<strong>in</strong>g additional methane gas:<br />

C + 2H2→ CH4<br />

KUNGLIGA TEKNISKA HÖGSKOLAN<br />

25 | Page