Untitled - HUBER

Untitled - HUBER

Untitled - HUBER

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

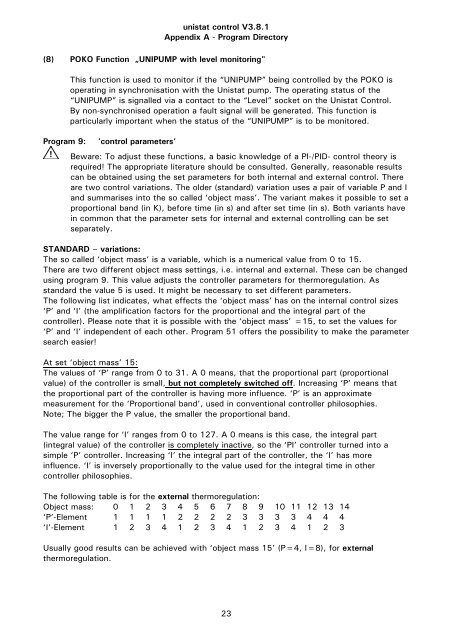

unistat control V3.8.1<br />

Appendix A - Program Directory<br />

(8) POKO Function „UNIPUMP with level monitoring"<br />

This function is used to monitor if the “UNIPUMP” being controlled by the POKO is<br />

operating in synchronisation with the Unistat pump. The operating status of the<br />

“UNIPUMP” is signalled via a contact to the “Level” socket on the Unistat Control.<br />

By non-synchronised operation a fault signal will be generated. This function is<br />

particularly important when the status of the “UNIPUMP” is to be monitored.<br />

Program 9: ‘control parameters’<br />

! Beware: To adjust these functions, a basic knowledge of a PI-/PID- control theory is<br />

required! The appropriate literature should be consulted. Generally, reasonable results<br />

can be obtained using the set parameters for both internal and external control. There<br />

are two control variations. The older (standard) variation uses a pair of variable P and I<br />

and summarises into the so called ‘object mass’. The variant makes it possible to set a<br />

proportional band (in K), before time (in s) and after set time (in s). Both variants have<br />

in common that the parameter sets for internal and external controlling can be set<br />

separately.<br />

STANDARD – variations:<br />

The so called ‘object mass’ is a variable, which is a numerical value from 0 to 15.<br />

There are two different object mass settings, i.e. internal and external. These can be changed<br />

using program 9. This value adjusts the controller parameters for thermoregulation. As<br />

standard the value 5 is used. It might be necessary to set different parameters.<br />

The following list indicates, what effects the ‘object mass’ has on the internal control sizes<br />

‘P’ and ‘I’ (the amplification factors for the proportional and the integral part of the<br />

controller). Please note that it is possible with the ‘object mass’ =15, to set the values for<br />

‘P’ and ‘I’ independent of each other. Program 51 offers the possibility to make the parameter<br />

search easier!<br />

At set ‘object mass’ 15:<br />

The values of ‘P’ range from 0 to 31. A 0 means, that the proportional part (proportional<br />

value) of the controller is small, but not completely switched off. Increasing ‘P’ means that<br />

the proportional part of the controller is having more influence. ‘P’ is an approximate<br />

measurement for the ‘Proportional band’, used in conventional controller philosophies.<br />

Note; The bigger the P value, the smaller the proportional band.<br />

The value range for ‘I’ ranges from 0 to 127. A 0 means is this case, the integral part<br />

(integral value) of the controller is completely inactive, so the ‘PI’ controller turned into a<br />

simple ‘P’ controller. Increasing ‘I’ the integral part of the controller, the ‘I’ has more<br />

influence. ‘I’ is inversely proportionally to the value used for the integral time in other<br />

controller philosophies.<br />

The following table is for the external thermoregulation:<br />

Object mass: 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14<br />

‘P’-Element 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4<br />

‘I’-Element 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3<br />

Usually good results can be achieved with ‘object mass 15’ (P=4, I=8), for external<br />

thermoregulation.<br />

23