Full Issue (17 MB) - Pile Driving Contractors Association

Full Issue (17 MB) - Pile Driving Contractors Association

Full Issue (17 MB) - Pile Driving Contractors Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

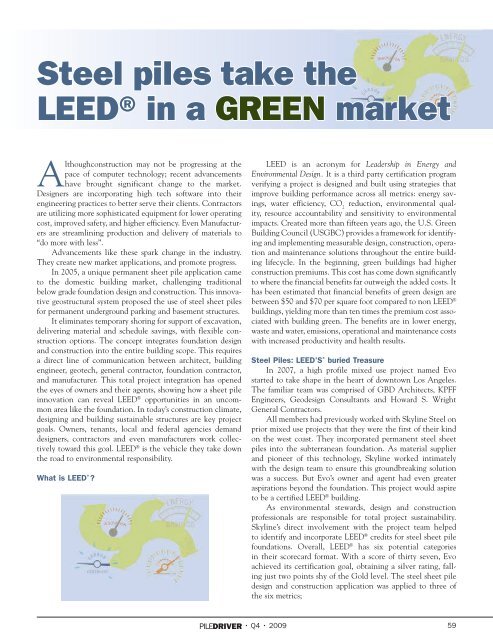

Steel piles take the<br />

LEED® in a GREEN market<br />

Althoughconstruction may not be progressing at the<br />

pace of computer technology; recent advancements<br />

have brought significant change to the market.<br />

Designers are incorporating high tech software into their<br />

engineering practices to better serve their clients. <strong>Contractors</strong><br />

are utilizing more sophisticated equipment for lower operating<br />

cost, improved safety, and higher efficiency. Even Manufacturers<br />

are streamlining production and delivery of materials to<br />

“do more with less”.<br />

Advancements like these spark change in the industry.<br />

They create new market applications, and promote progress.<br />

In 2005, a unique permanent sheet pile application came<br />

to the domestic building market, challenging traditional<br />

below grade foundation design and construction. This innovative<br />

geostructural system proposed the use of steel sheet piles<br />

for permanent underground parking and basement structures.<br />

It eliminates temporary shoring for support of excavation,<br />

delivering material and schedule savings, with flexible construction<br />

options. The concept integrates foundation design<br />

and construction into the entire building scope. This requires<br />

a direct line of communication between architect, building<br />

engineer, geotech, general contractor, foundation contractor,<br />

and manufacturer. This total project integration has opened<br />

the eyes of owners and their agents, showing how a sheet pile<br />

innovation can reveal LEED ® opportunities in an uncommon<br />

area like the foundation. In today’s construction climate,<br />

designing and building sustainable structures are key project<br />

goals. Owners, tenants, local and federal agencies demand<br />

designers, contractors and even manufacturers work collectively<br />

toward this goal. LEED ® is the vehicle they take down<br />

the road to environmental responsibility.<br />

What is LEED ® ?<br />

LEED is an acronym for Leadership in Energy and<br />

Environmental Design. It is a third party certification program<br />

verifying a project is designed and built using strategies that<br />

improve building performance across all metrics: energy savings,<br />

water efficiency, CO 2<br />

reduction, environmental quality,<br />

resource accountability and sensitivity to environmental<br />

impacts. Created more than fifteen years ago, the U.S. Green<br />

Building Council (USGBC) provides a framework for identifying<br />

and implementing measurable design, construction, operation<br />

and maintenance solutions throughout the entire building<br />

lifecycle. In the beginning, green buildings had higher<br />

construction premiums. This cost has come down significantly<br />

to where the financial benefits far outweigh the added costs. It<br />

has been estimated that financial benefits of green design are<br />

between $50 and $70 per square foot compared to non LEED ®<br />

buildings, yielding more than ten times the premium cost associated<br />

with building green. The benefits are in lower energy,<br />

waste and water, emissions, operational and maintenance costs<br />

with increased productivity and health results.<br />

Steel <strong>Pile</strong>s: LEED’S ® buried Treasure<br />

In 2007, a high profile mixed use project named Evo<br />

started to take shape in the heart of downtown Los Angeles.<br />

The familiar team was comprised of GBD Architects, KPFF<br />

Engineers, Geodesign Consultants and Howard S. Wright<br />

General <strong>Contractors</strong>.<br />

All members had previously worked with Skyline Steel on<br />

prior mixed use projects that they were the first of their kind<br />

on the west coast. They incorporated permanent steel sheet<br />

piles into the subterranean foundation. As material supplier<br />

and pioneer of this technology, Skyline worked intimately<br />

with the design team to ensure this groundbreaking solution<br />

was a success. But Evo’s owner and agent had even greater<br />

aspirations beyond the foundation. This project would aspire<br />

to be a certified LEED ® building.<br />

As environmental stewards, design and construction<br />

professionals are responsible for total project sustainability.<br />

Skyline’s direct involvement with the project team helped<br />

to identify and incorporate LEED ® credits for steel sheet pile<br />

foundations. Overall, LEED ® has six potential categories<br />

in their scorecard format. With a score of thirty seven, Evo<br />

achieved its certification goal, obtaining a silver rating, falling<br />

just two points shy of the Gold level. The steel sheet pile<br />

design and construction application was applied to three of<br />

the six metrics;<br />

• Q4 • 2009<br />

59