Full Issue (17 MB) - Pile Driving Contractors Association

Full Issue (17 MB) - Pile Driving Contractors Association

Full Issue (17 MB) - Pile Driving Contractors Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

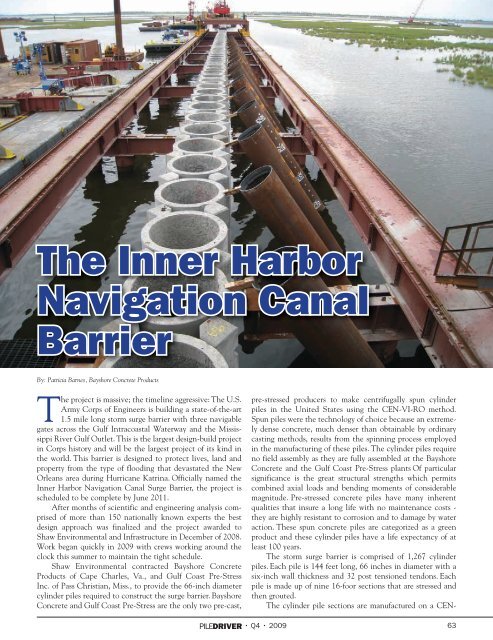

The Inner Harbor<br />

Navigation Canal<br />

Barrier<br />

By: Patricia Barnes, Bayshore Concrete Products<br />

The project is massive; the timeline aggressive: The U.S.<br />

Army Corps of Engineers is building a state-of-the-art<br />

1.5 mile long storm surge barrier with three navigable<br />

gates across the Gulf Intracoastal Waterway and the Mississippi<br />

River Gulf Outlet. This is the largest design-build project<br />

in Corps history and will be the largest project of its kind in<br />

the world. This barrier is designed to protect lives, land and<br />

property from the type of flooding that devastated the New<br />

Orleans area during Hurricane Katrina. Officially named the<br />

Inner Harbor Navigation Canal Surge Barrier, the project is<br />

scheduled to be complete by June 2011.<br />

After months of scientific and engineering analysis comprised<br />

of more than 150 nationally known experts the best<br />

design approach was finalized and the project awarded to<br />

Shaw Environmental and Infrastructure in December of 2008.<br />

Work began quickly in 2009 with crews working around the<br />

clock this summer to maintain the tight schedule.<br />

Shaw Environmental contracted Bayshore Concrete<br />

Products of Cape Charles, Va., and Gulf Coast Pre-Stress<br />

Inc. of Pass Christian, Miss., to provide the 66-inch diameter<br />

cylinder piles required to construct the surge barrier. Bayshore<br />

Concrete and Gulf Coast Pre-Stress are the only two pre-cast,<br />

pre-stressed producers to make centrifugally spun cylinder<br />

piles in the United States using the CEN-VI-RO method.<br />

Spun piles were the technology of choice because an extremely<br />

dense concrete, much denser than obtainable by ordinary<br />

casting methods, results from the spinning process employed<br />

in the manufacturing of these piles. The cylinder piles require<br />

no field assembly as they are fully assembled at the Bayshore<br />

Concrete and the Gulf Coast Pre-Stress plants Of particular<br />

significance is the great structural strengths which permits<br />

combined axial loads and bending moments of considerable<br />

magnitude. Pre-stressed concrete piles have many inherent<br />

qualities that insure a long life with no maintenance costs -<br />

they are highly resistant to corrosion and to damage by water<br />

action. These spun concrete piles are categorized as a green<br />

product and these cylinder piles have a life expectancy of at<br />

least 100 years.<br />

The storm surge barrier is comprised of 1,267 cylinder<br />

piles. Each pile is 144 feet long, 66 inches in diameter with a<br />

six-inch wall thickness and 32 post tensioned tendons. Each<br />

pile is made up of nine 16-foor sections that are stressed and<br />

then grouted.<br />

The cylinder pile sections are manufactured on a CEN-<br />

• Q4 • 2009<br />

63