Tender Document for Repowering Project of Ghorasal 3rd Unit - BPDB

Tender Document for Repowering Project of Ghorasal 3rd Unit - BPDB

Tender Document for Repowering Project of Ghorasal 3rd Unit - BPDB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

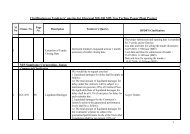

interconnecting piping & valves, spray water manifold and spray nozzles.<br />

The various components <strong>of</strong> the system are shown in schematic diagram<br />

enclosed. Wash water tank shall be used to draw and mix wash water and<br />

detergent to the required dilution, compressed air taken from existing<br />

instrument air header shall be used to pressurise this fluid and to <strong>for</strong>ward to<br />

the spray water manifold. The spray nozzles shall make a high velocity jet<br />

spray to clean the compressor blades while the rotor shall be kept in<br />

spinning operation.<br />

i) Wash water tank shall be a cylindrical pressure vessel with dished<br />

ends on both sides. This tank shall be provided with necessary<br />

appurtenances and accessories such as<br />

a) Compressed air inlet.<br />

b) Water inlet with isolation valve and inlet strainer.<br />

c) Breather vent with isolation valve.<br />

d) Drain line with isolation valve.<br />

e) Detergent inlet nozzle with isolation valve.<br />

f) Pressurised water outlet with isolation valve.<br />

g) Level gauge glass with isolation valves.<br />

h) Hand holes with covers.<br />

i) Pressure relief valves.<br />

j) Pressure gauge connection.<br />

ii)<br />

iii)<br />

iv)<br />

Detergent hopper to hold the detergent <strong>for</strong> every wash cycle.<br />

Interconnecting piping between wash water tank and compressor<br />

spray system. This line shall be provided with strainer, drain valve,<br />

pressure gauge, and orifice plate.<br />

Water wash manifolds.<br />

This manifold shall be located within the compressor inlet and it<br />

shall distribute the wash water into the compressor inlet air stream.<br />

The manifold shall be equipped with a drain valve.<br />

v) Set <strong>of</strong> spray nozzles shall effectively spray water, detergent water<br />

<strong>for</strong> efficient cleaning.<br />

To introduce the above-mentioned wet washing system <strong>for</strong><br />

compressor cleaning <strong>of</strong> gas turbine generating unit. The following<br />

works shall be re<strong>for</strong>med:<br />

a) Installation <strong>of</strong> the wash water system.<br />

b) Providing spray nozzle on compressor inlet manifolds.<br />

c) Taking a tapping from instrument compressed air header to<br />

supply compressed air <strong>for</strong> washing system.<br />

d) Routing the wash water to the Gas Turbine Compressor.<br />

e) Providing various drain lines with isolation valves at drain<br />

points from the compressor and turbine to drain the wash<br />

water during washing cycle.<br />

f) Providing bearing seal air piping to protect bearing during<br />

washing cycle.<br />

g) Drainage system to drain out the water.<br />

Re-Powering <strong>Ghorasal</strong> 210 MW 3 rd <strong>Unit</strong> (Vol-2A <strong>of</strong> 2) 46