Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WORKSHOP<br />

building the stqfion<br />

Ifyou're building this workstation, itt a sure<br />

bet you already have the most important<br />

thing - a pocket-hole jig.To make assembling<br />

the workstation quick and easy, you<br />

can use the jig itself to create the joinery.<br />

It's also used as an alignment tool when<br />

building the workstation.<br />

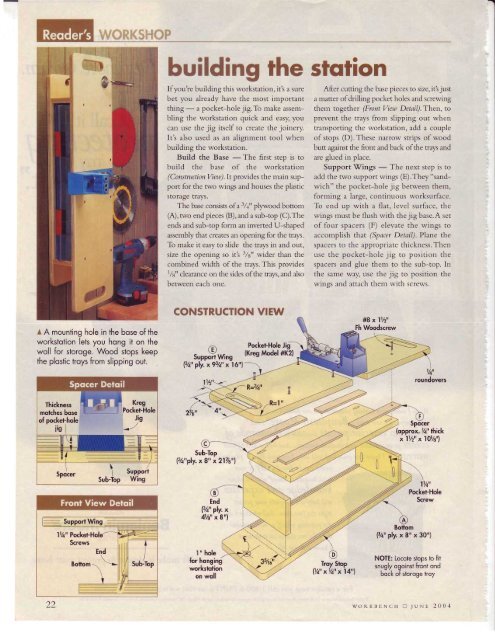

Build the Base - The first step is to<br />

build the base of the workstation<br />

(Construction View). It provides the main support<br />

for the two wings and houses the plastic<br />

storage ffays.<br />

The base consisb of a3/4" plywood boaom<br />

(A), t*o end pieces (B), and a sub-top (C).The<br />

ends and sub-top form an inverted U-shaped<br />

assembly that creates an opening for the trays.<br />

To make it easy to slide the trays in and out,<br />

size the opening so it's 3/s" wider than the<br />

combined width of the trays. This provides<br />

1/s" clearance on the sides of the traw, and also<br />

between each one.<br />

coNsTRucTroN vrEw<br />

After cutting the base pieces to size, itt just<br />

a matter of drilling pocket holes and screwing<br />

them together (Front View Detail).Then, to<br />

prevent the trays from slipping out when<br />

transporting the workstation, add a couple<br />

of stops (D).These narrow strips of wood<br />

butt agairst the front and back ofthe trala and<br />

are glued in place.<br />

Support'Wings - The next step is to<br />

add the two support wings (E).They"sandwich"<br />

the pocket-hole jig between them,<br />

forming a large, continuous worksuface.<br />

To end up with a flat, level surface, the<br />

wings must be flush with the jig base.A set<br />

of four spacers (F) elevate the wings to<br />

accomplish that (Spaeer Detail). Plane the<br />

spacers to the appropriate thickness.Then<br />

use the pocket-hole jig to position the<br />

spacers and glue them to the sub-top. In<br />

the same way, use the jig to position the<br />

wings and attach them with screws.<br />

A A mounfing hole in the bose of the<br />

workstotion lets you hong it on the<br />

woll for storoge. <strong>Wood</strong> stops keep<br />

the plostic troys from slipping ouf.<br />

PockeFHole Jig<br />

@ (Kreg Model#K2l<br />

SupportWing<br />

F/a" pV. x 9Bld'x l6"l<br />

U1.'<br />

roundovers<br />

Thickness<br />

mokhes bose<br />

Sub-Top<br />

(%"ph.x 8" x2l7/s"l<br />

Spd-cer<br />

(opprox. %" thick<br />

xllz" xl0Wl<br />

lr/a"<br />

PockeFHole<br />

Screw<br />

l " hole<br />

for hongin{<br />

worksiofion<br />

on woll<br />

l%'PV.x8"x30"f<br />

NOTE: Locote stops to fit<br />

,. 'f snugly ogoinst front ond<br />

bock of sioroge troy<br />

woRKBENcH ft luNr 2004

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)