You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ossembling the<br />

STORAGE TRAYS<br />

With the rail assemblies complete,<br />

you can turn your attention to the<br />

trays that fit inside them.<br />

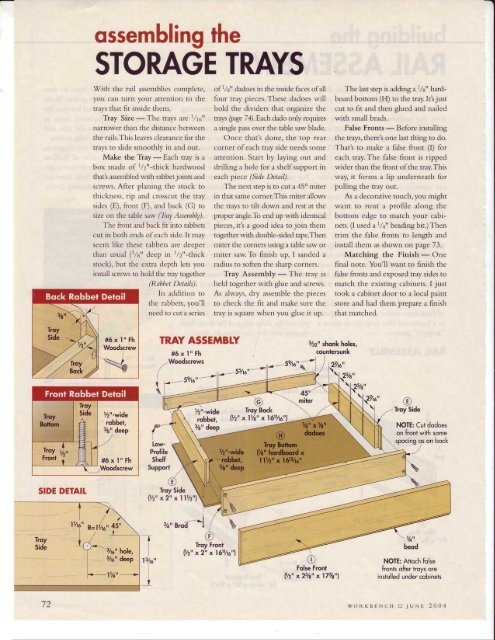

Tiay Size - The trays are l/16"<br />

narrower than the distance berween<br />

the rails.This leaves clearance for the<br />

trays to slide smoothly in and out.<br />

Make the Tiray - Each tray is a<br />

box made of 1/2"-thick hardwood<br />

that's assembied with rabbet joints and<br />

screws. After planing the stock to<br />

thickness, rip and crosscut the tray<br />

sides (E), front (F), and back (G) to<br />

size on the table saw (Tiay Assembly).<br />

The front and back fit into rabbets<br />

cut in both ends of each side. It rnay<br />

seem like these rabbets are deeper<br />

than usual (3/s" deep in l/2"-thick<br />

stock), but the extra depth lets you<br />

install screws to hold the tray together<br />

(Rabbet Detaik).<br />

In addition to<br />

the rabbets, you'Il<br />

need to cut a series<br />

of1ls" dadoes in the inside faces ofall<br />

four tray pieces. These dadoes will<br />

hold the dividers that organize the<br />

rays (page 74).Each dado only requires<br />

a single pass over the table saw blade.<br />

Once that's done, the top rear<br />

corner of each tray side needs some<br />

attention. Start by laying out and<br />

drilling a hole for a shelf support in<br />

each piece (Side Detail).<br />

The next step is to cut a 45o miter<br />

in that same corner.This miter allows<br />

the trays to tilt down and rest at the<br />

proper angle.To end up with identical<br />

pieces, it's a good idea to join them<br />

together with double-sided tape.Then<br />

miter the corners using a table saw or<br />

miter saw. To finish up, I sanded a<br />

radius to soften the sharp corners.<br />

Tray Assembly - The tray is<br />

held together with glue and screws.<br />

As always, dry assemble the pieces<br />

to check the fit and make sure the<br />

tray is square when you glue it up.<br />

The last step is adding al/eu hardboard<br />

bottom (H) to the tray. Itt just<br />

cut to fit and then glued and nailed<br />

with small brads.<br />

False Fronts _ Before ll5galling<br />

the trays, there's one last thing to do.<br />

That's to make a false front (l) for<br />

each tray. The false front is ripped<br />

wider than the front of the tray.This<br />

way, it forms a lip underneath for<br />

pulling the tray out.<br />

As a decorative touch, you might<br />

want to rout a profile along the<br />

bottom edge to match your cabinets.<br />

(l used a1/a" beadingbit.) Then<br />

trim the false fronts to length and<br />

install them as shown on page 73.<br />

Matching the Finish - One<br />

{inal note. You'll want to finish the<br />

false fronts and exposed tray sides to<br />

match the existing cabinets. I just<br />

took a cabinet door to a local paint<br />

store and had them prepare a finish<br />

that matched.<br />

TRAY ASSE'VIBIY<br />

#6xl"Fh<br />

-<strong>Wood</strong>screws<br />

7rz" shonk holes,<br />

countersunk<br />

59A0"-4 27Ac"<br />

(<br />

q<br />

low-<br />

Profile<br />

Shelf<br />

Support<br />

SeAe"<br />

@<br />

Troy Side<br />

NOTE: Cut dodoes<br />

'\....<br />

on front with some<br />

spocing os on bock<br />

%<br />

SIDE DETAII.<br />

Troy Side \<br />

(/z"x2xll7z"l<br />

3/" Bro{-1 v,<br />

Troy Front<br />

l/2" x2" x l6l%a"l<br />

Folse Fronl<br />

I/2" x25/a" x lV/s"l<br />

U4"<br />

beod<br />

NOTE: Attoch forse<br />

fronls ofter lroys ore<br />

instolled under cobinets<br />

72<br />

woRKBENcH E JUNE 2004

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)