Elegant Entry Divider - Wood Tools

Elegant Entry Divider - Wood Tools

Elegant Entry Divider - Wood Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

uildi<br />

the stqtion<br />

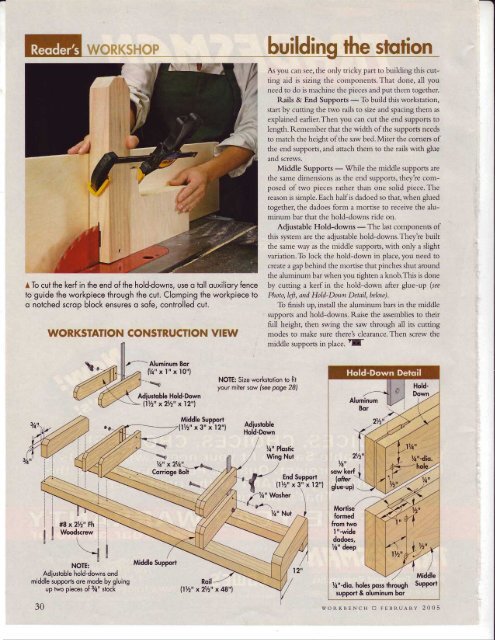

A To cut the kerf in the end of the holddowns, use o toll ouxiliory fence<br />

to guide the workpiece through the cut. Clomping the workpiece to<br />

o notched scrop block ensures o sofe, controlled cut.<br />

WORKSTATION CONSTRUCTION VIEW<br />

As you can see, the only tricky part to building this cutting<br />

aid is sizing the components. That done, all you<br />

need to do is machine the pieces and put them together.<br />

Rails & End Supports - To build this workstation,<br />

start by cutting the rwo rails to size and spacing thern as<br />

explained earlier.Then you can cut the end supports to<br />

length. Remember that the width of the supports needs<br />

to match the height of the saw bed. Miter the corners of<br />

the end supports, and attach them to the rails with glrre<br />

and screws.<br />

Middle Supports -<br />

While the middle supports are<br />

the same dimensions as the end supports, they're composed<br />

of two pieces rather than one solid piece. The<br />

reason is simple. Each half is dadoed so that, when glued<br />

together, the dadoes form a mortise to receive the aluminum<br />

bar that the hold-downs ride on.<br />

Adjustable Hold-downs - The last components of<br />

this system are the adjustable hold-downs.They re built<br />

the same way as the middle supports, with only a slight<br />

variation.To lock the hold-down in place, you need to<br />

create a gap behind the mortise that pinches shut around<br />

the aluminum bar when you tighten a knob.This is done<br />

by cutting a kerf in the hold-down<br />

Photo,left, and Hold-Down Detail, below).<br />

after glue-up (sae<br />

To finish up, install the aluminum bars in the middle<br />

supports and hold-downs. Raise the assemblies to their<br />

full height, then swing the saw through all its cutting<br />

modes to make sure there's clearance. Then screw the<br />

middle supports in place. ffi<br />

z--Aluminum Bor<br />

f/a"xl"x10")<br />

.'-\{<br />

Adiusioble Hold-Down<br />

llYz" x2Vz" x12"1<br />

NOTE: Size worksiotion to fir<br />

your miter sow {see poge 28)<br />

Middle Support<br />

(l7z"x3"xl2"l<br />

.\v<br />

.\0<br />

%" Ploslic<br />

Wing Nut<br />

lU{<br />

%"-dio.<br />

.11.'Jr'"'f;r'-qc<br />

_F<br />

q<br />

EndSupport<br />

(172" x 3" x l2"l<br />

I<br />

7th"wosh., \<br />

"f-- -a \<br />

#8x2Vz" Fh 1<br />

<strong>Wood</strong>screw<br />

\l<br />

)<br />

NOTE:<br />

Middle Support<br />

Adiustoble hold-downs ond<br />

middle supports ore mode by gluing<br />

up two pieces of 3/4rr<br />

Roil<br />

stock<br />

llVz" x2Vz" x 48"1<br />

30<br />

h"-dio. holes poss through Support<br />

supporl & oluminum bor<br />

woRKBENcH ft FEBRUAnv 2005

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)