Elegant Entry Divider - Wood Tools

Elegant Entry Divider - Wood Tools

Elegant Entry Divider - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

skill<br />

Builder<br />

Tnhil*,1 lr*w $efru,p<br />

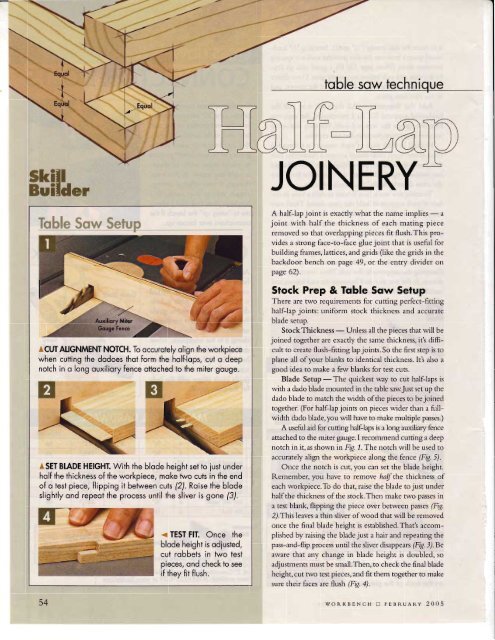

ICUTAUGNMENT NOTCH. To occurotely olign the workpiece<br />

when cuiting the dodoes thot form the holHops, cut o deep<br />

notch in o long ouxiliory fence ottoched to the miter gouge.<br />

f SET BLADE HEIGHT. With the blode height set to iust under<br />

holf the thickness of the workpiece, moke iwo cuts in the end<br />

of o test piece, flipping it between cuts (2). Roise the blode<br />

sl;ghtly ond repeot ihe process until the sliver is gone /3i.<br />

'{ TEST FlT. Once the<br />

blode height is odlusted,<br />

cut robbets in two tesr<br />

pieces, ond check to see<br />

if they fit flush.<br />

Tl f'<br />

D Il-:<br />

LIAIA J\<br />

, tt . r<br />

Ioole sow tecnntoue<br />

ll<br />

6)T.^\<br />

\-r@LlU<br />

ll<br />

JOINERY^<br />

A half-lap joint is exactly what the nanre irnplies - a<br />

joint with half the thickness of each mating piece<br />

removed so that overlapping pieces fit flush.This provides<br />

a strong fice-to-face glue joint that is useful for<br />

building franres, lattices, and grids (like the grids ir.r the<br />

backdoor bench on page 49, or the entry divider on<br />

page 62).<br />

Sfock Prep & Toble Sqw Setup<br />

There are two requirenrer-rts for cuttir-rg perfect-fitting<br />

half-lap joints: unifornr stock thickness and accurate<br />

blade setup.<br />

Stock Thickness - Ulnless all the pieces that will be<br />

joined together are exactly the sar.ne thickness, it's di{Ecult<br />

to create flush-fitting lap joints. So the first step is to<br />

plane all of 1'our blanks to identical thickness. It'.s also a<br />

good idea to make a few blanks for test cuts.<br />

Blade Setup - The quickest way to cut half-laps is<br />

with a dado blade mounted in tl.re table saw.Just set up the<br />

dado blade to match the width of the pieces to be joined<br />

together. (For half-lap joints on pieces rvider than a fullwidth<br />

dado blade, you will have to rnake nrultiple passes.)<br />

A useful aid for cutting half-laps is a long auxiliary fence<br />

attached to the miter gauge. I recomr.nend cutting a deep<br />

notch in it, as shown in Fig. 1. The notch will be used ro<br />

accurately align the workpiece along the fence (Fi.q. 5).<br />

Once the notch is cllt, you can set the blade height.<br />

Renrember, you have to remove lmlf rhe thickness of<br />

each workpiece.To do that, raise the blade to just under<br />

half the thickness of the stock.Then make fwo passes in<br />

a test blank, flipping the piece over between passes (Fig<br />

2).Thts leaves a thin sliver of wood that will be removed<br />

once the final blade height is established.That's accomplished<br />

by raising the bladejust a hair and repeating the<br />

pass-arrd-fli process until the sliver disappears (Fig.3).Be<br />

aware that any change in blade height is doubled, so<br />

adjustments nlust be small.Then, to check the final blade<br />

height, cut rwo test pieces, and fit them to€iether ro make<br />

sure their faces are flush (Fig. 4).<br />

54 woRKBENCH ! FEBRUAI{y 2005

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)