4 - Certificazione energetica edifici

4 - Certificazione energetica edifici

4 - Certificazione energetica edifici

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

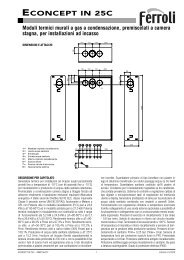

Wall-hung pre-mixed condensation gas boilers<br />

•“termo” FUTURIA N<br />

- Ultra-high efficiency proof condensation boilers, suitable for heating.<br />

- Ultra-high heat exchange aluminium lamellar exchanger.<br />

- Flame injection pre-mixed ceramic burner.<br />

- Ideal for low temperature system operation.<br />

- Suitable for water and electrical connection to the boiler kit (boiler<br />

circulator and temperature probe).<br />

- Special casting aluminium corrosion proofing enbloc exchanger.<br />

- Adjustable opening pneumatic gas valve.<br />

- Microprocessor electronic card suitable for connection to the cascade<br />

control board and possible external probe.<br />

- Variable speed fan.<br />

- Ionization flame control electronic ignition.<br />

- Electronically controlled continuous modulation for both heating<br />

circuits with steady air/gas ratio.<br />

- Natural gas or G.P.L. operation.<br />

- Instruments for retraction unit control and regulation.<br />

- High-prevalence circulator.<br />

- 10 Lt. expansion tank (models 15, 25 and 35).<br />

- Check valve.<br />

- G.P.L. kit supplied with the boiler.<br />

- Water trap siphon<br />

- Class: NOx = 5.<br />

- IP X4D protection degree.<br />

Classe<br />

NOx<br />

5<br />

• Installation and Maintenance<br />

- Series of modules being cascade connected can be managed and easily<br />

assembled. The machine electronic unit is arranged for the connection<br />

of the control room to the cascade control and managament<br />

microprocessor.<br />

- Easy installation thanks to template connections and water connection<br />

kits (on demand).<br />

- Maintenance is made simple thanks to easy accessibility to internal<br />

components.<br />

• Optional accessories<br />

- For accessories suitable for FUTURIA N boiler, see page 85.<br />

- Flue inlet/outlet kits are not included in the supply. See accessories on<br />

demand on page 85.<br />

- Water connection kits are not included in the supply. See accessories on<br />

demand on page 85.<br />

- When installing a Ø60/ Ø100 concentric kit, a “flanged<br />

concentric connection kit” (code 08516310) shall be assembled<br />

between the boiler and the concentric kit.<br />

800<br />

Aria* Air*<br />

B C D<br />

Aria* Air*<br />

Exaust* Fumi*<br />

E<br />

• Certification<br />

- FUTURIA N boilers are EC type approved.<br />

A 410<br />

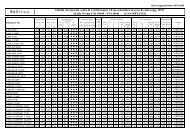

boiler furnace power useful efficiency Maximum power A B C D E Weight<br />

type a 50/30°C a 80/60°C pressure voltage<br />

kW kcal/h 100% 30% 100% bar V/Hz mm. mm. mm. mm. mm. Kg<br />

FUTURIA N 15 MT W TOP/IT 3,6÷ 15,3 3.096÷ 13.158 106,5 109 98 3 230/50 450 120 120 105 180 46,5<br />

FUTURIA N 25 MT W TOP/IT 7,5÷ 25,2 6.450÷ 21.670 104,7 109 98 3 230/50 450 120 120 105 180 47,5<br />

FUTURIA N 35 MT W TOP/IT 10,4÷ 34,8 8.940÷ 29.920 104,7 109,1 99,5 3 230/50 490 120 120 125 180 49,5<br />

FUTURIA N 50 MT W TOP/IT 13,8÷ 46 11.868÷ 39.560 105,3 109 98,2 3 230/50 600 120 120 180 130 51,5<br />

* Flue connections: concentric or split discharge<br />

boiler Fuel boiler 50/30°C useful power 80/60°C useful power<br />

code type kW kcal/h kW kcal/h<br />

00905520 nat. gas/LPG FUTURIA N 15 MT W TOP/IT 3,8÷ 16,3 3.268÷ 14.018 3,5÷ 15 3.010÷ 12.900<br />

00905560 nat. gas/LPG FUTURIA N 25 MT W TOP/IT 8÷ 26,4 6.880÷ 22.700 7,3÷ 24,7 6.280÷ 21.240<br />

00905530 nat. gas/LPG FUTURIA N 35 MT W TOP/IT 11,1÷ 36,4 9.540÷ 31.300 10,2÷ 34,6 8.770÷ 29.750<br />

00905550 nat. gas/LPG FUTURIA N 50 MT W TOP/IT 14,4÷ 48,4 12.384÷ 41.624 13,6÷ 45,2 11.696÷ 38.872<br />

42