Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R á b a A x l e L t d<br />

The Rába <strong>Axle</strong> <strong>Ltd</strong>. boasts great experience and<br />

achievements in the research and development, and<br />

manufacture of axles and axle components as well.<br />

Its products are primarily installed in<br />

• medium- and heavy-duty trucks,<br />

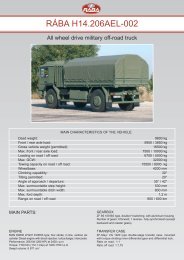

• military trucks,<br />

• specialty vehicles: tractors and construction equipments,<br />

• buses.<br />

• Tool manufacturing with CAM applications<br />

• Heat treatment (isothermal annealing, normalizing,<br />

hardening and tempering equipments)<br />

• Machining capacity<br />

• Surface treatment<br />

• Test and measurement laboratories<br />

• Assembly plant<br />

• Parts supply in painted, packed condition<br />

• Logistic solutions<br />

The vertical integration of Rába <strong>Axle</strong> <strong>Ltd</strong>. is a great<br />

advantage in meeting customer needs fast and flexilble.<br />

Cooperation<br />

The design engineers of the company have been<br />

cooperating with experts of international automotive<br />

companies for a long time. The Rába <strong>Axle</strong> <strong>Ltd</strong>. designs and<br />

tests its products in close cooperation with its automotive<br />

partners, and is ready to satisfy the most unique customer<br />

requirements.<br />

Customer focus:<br />

The organization of the company, its employees and<br />

technical equipment (CAD, electronic customer relationship<br />

management, etc.) are all lined up to fully serve the needs<br />

of OEM and Tier1 partners. We offer our customers great<br />

flexibility and a fast access to market opportunities by<br />

means of co-operation already in the design phase.<br />

Vertical integration:<br />

The strength of the Rába <strong>Axle</strong> lies in the vertically<br />

integrated production process which makes Rába capable<br />

of offering complex package to its customers including:<br />

Value creation<br />

As a market player specialized in axle and axle components<br />

production, the Rába <strong>Axle</strong> creates value to OEMs with its<br />

cost-efficient, high quality products that are designed to<br />

meet specific customer needs. The company received the<br />

certificate of ISO/TS 16949 in 2003, which was renewed in<br />

2006. The ISO/TS 16949 Quality Assurance System applicable<br />

in automotive industry provides guarantee for steady and<br />

reliable quality.<br />

Our company obtained the Certificate of Approval of ISO<br />

14001 Environmental Management System Standards in<br />

2002 as well.<br />

1<br />

• Engineering activity<br />

– forgings are designed with 3D ProE software<br />

– part deformation simulation in the die through<br />

MSC Autoforge<br />

• Forging capacity<br />

– Maxima presses 1000/2500/4000/6300 t<br />

– Hot extruding 800/1000 t<br />

– I-beam production line (400 kJ counter blow<br />

hammer)<br />

• Foundry producing nodular iron<br />

Rába <strong>Axle</strong> <strong>Ltd</strong>.